Glue sealing machine for mobile phone screen side edges

A technology of mobile phone screen and glue sealing machine, which is applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of incomplete cleaning, difficult operation, low operation efficiency, etc., to achieve simple structure and operation method, improve Operational efficiency, the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

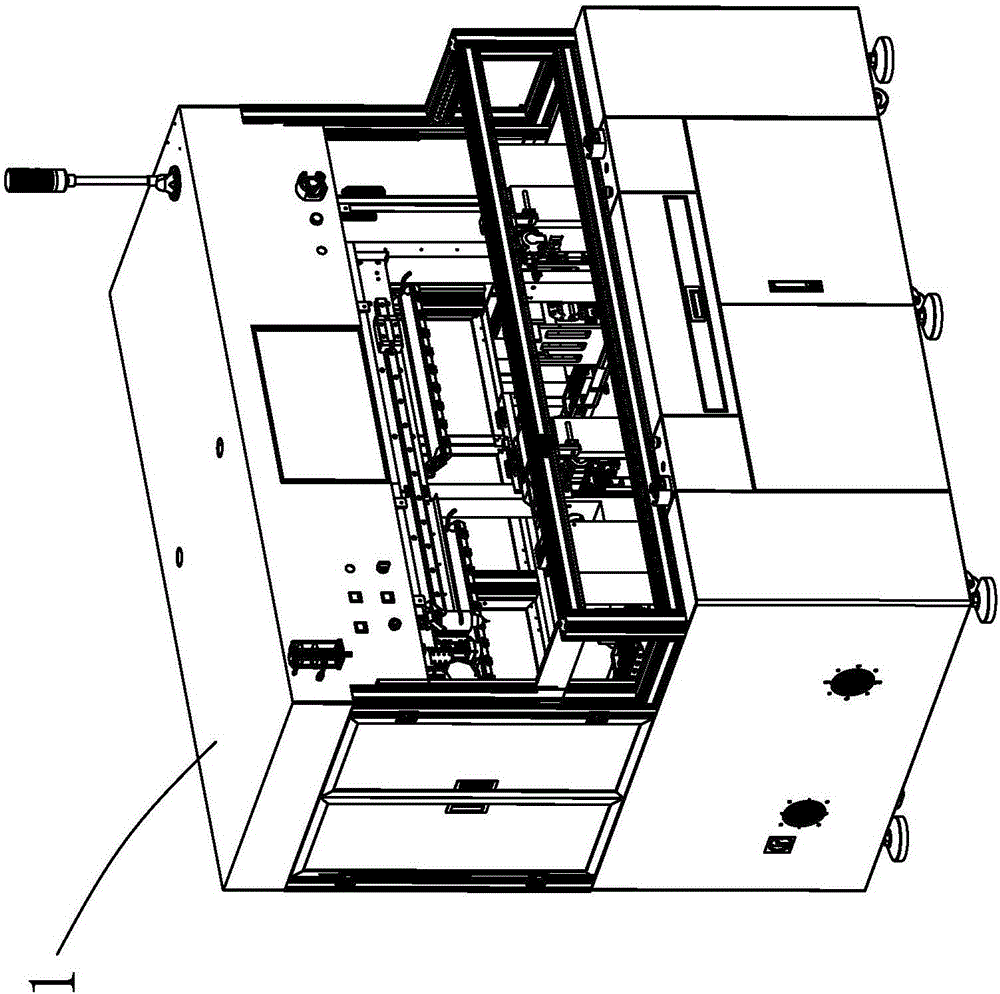

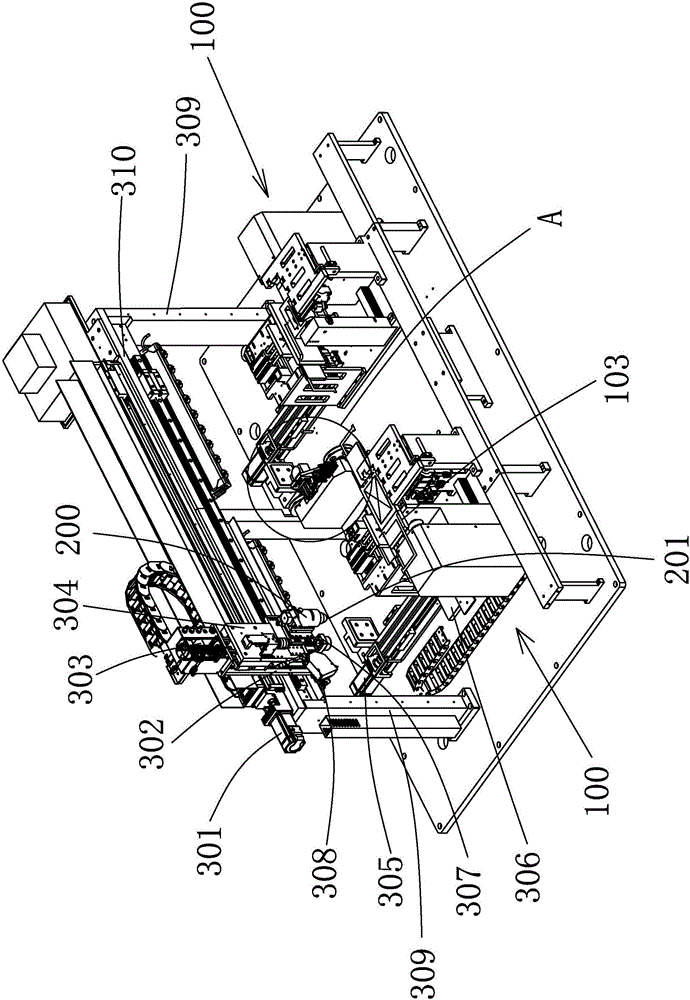

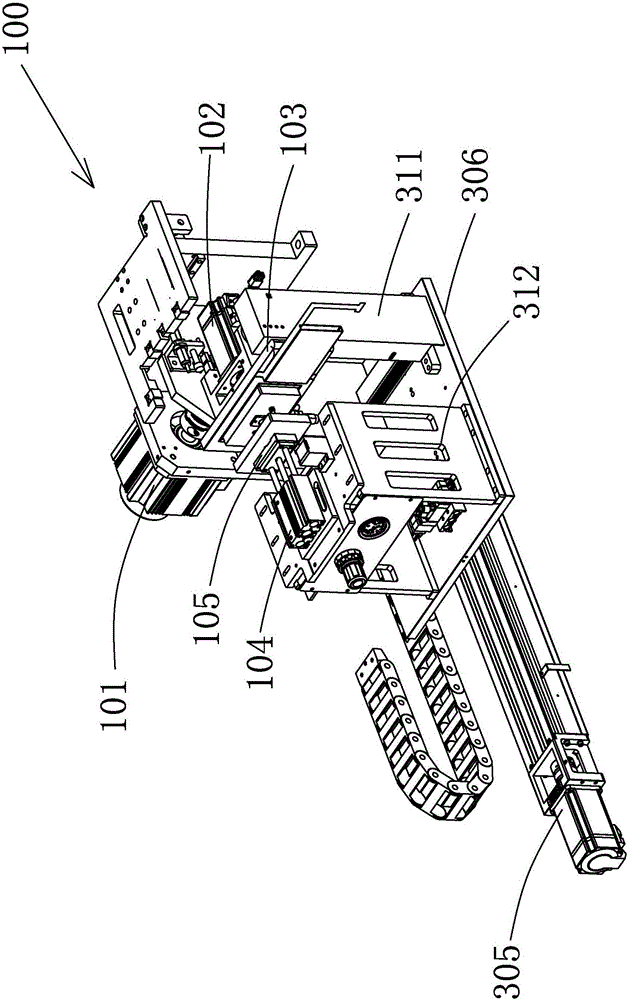

[0027] Mobile phone screen side sealing machine, see Figure 1 ~ Figure 3 As shown, it includes the adjustment device and the sealing device on the side of the mobile phone screen. The adjustment device includes at least one adjustment mechanism 100 and at least one action control mechanism of the adjustment mechanism 100. Each adjustment mechanism is respectively fixed on the action control mechanism of each adjustment mechanism. The action end of each adjustment mechanism 100 is controlled by the action control mechanism of each adjustment mechanism 100 to move along the Y axis. Each adjustment mechanism 100 includes a first driving member 101, a second driving member 102, and The working platform 103 of the mobile phone screen, the working platform 103 is positioned at the output end of the second driving part 102, the second driving part is positioned at the output end of the first driving part 101, and the first driving part 101 can drive the second driving part 102 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com