Continuous casting billet online weight fixing system

A continuous casting billet and weight technology, which is applied in the configuration of casting equipment, manufacturing tools, indicating equipment/measuring equipment, etc., can solve the problems of inability to meet the requirements of efficient continuous casting production, short life of load cells, and high temperature of continuous casting billets. , to meet the requirements of high-efficiency continuous casting production, long service life, and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

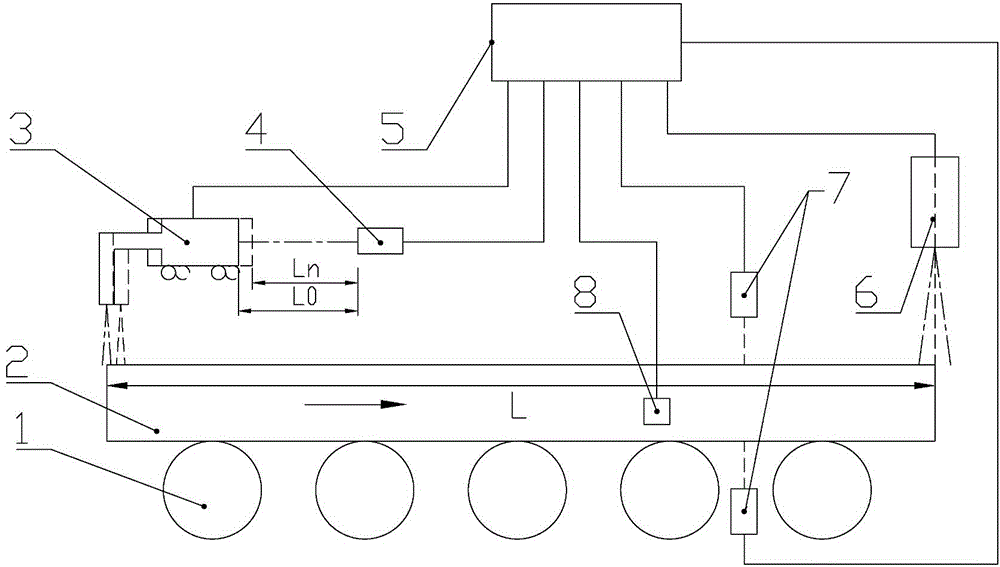

[0014] Such as figure 1 As shown, the continuous casting slab 2 moves from left to right on the roller table 1 at a certain speed, and the flame cutting device 3 is arranged at the left end of the continuous casting slab 2 to cut off the continuous casting slab. When cutting the continuous casting slab, it synchronously follows The continuous casting slab moves to the right, and after the cutting is completed, it returns to the waiting position to the left and waits for the next cutting. The waiting position refers to the position where the flame cutting device returns to the original position after each cutting is completed until it stops and waits for the next cutting. The weight measuring device for measuring the weight of the continuous casting slab includes a computer 5 and a length measurement module, a width measurement module and a thickness measurement module for measuring the length, width and thickness of the continuous casting slab electrically connected to it, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com