Machining tool suitable for shaft workpiece

A shaft workpiece and tooling technology, which is applied in the field of shaft workpiece processing tooling, can solve the problems of inability to guarantee the coaxiality of the workpiece, poor surface quality, etc., and achieve the effect of ensuring the coaxiality and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

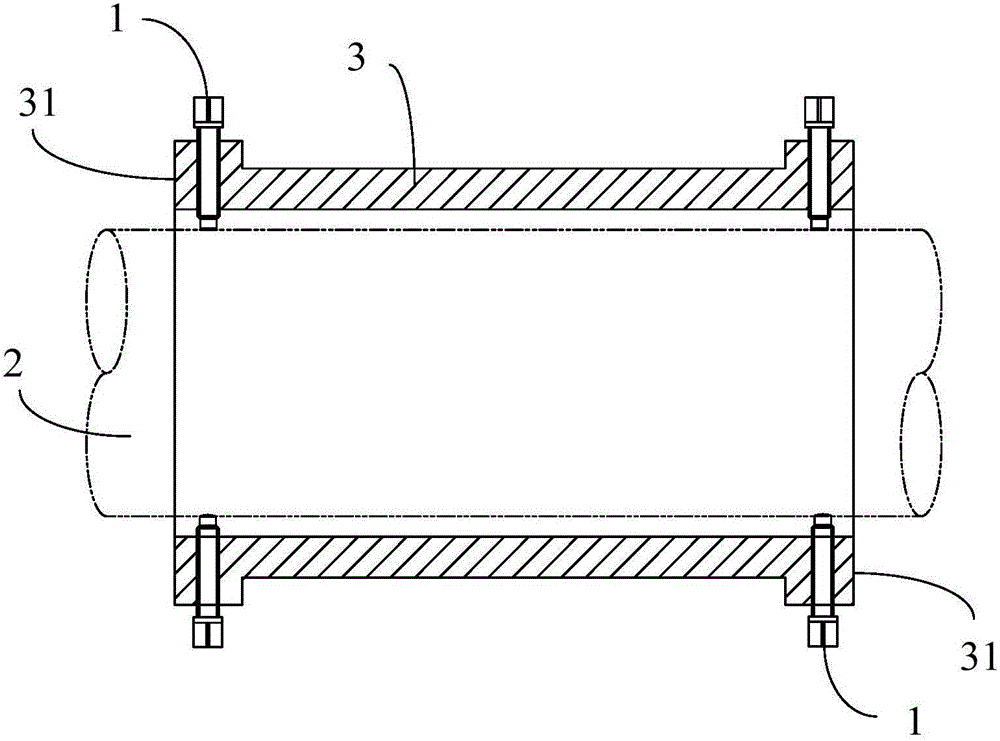

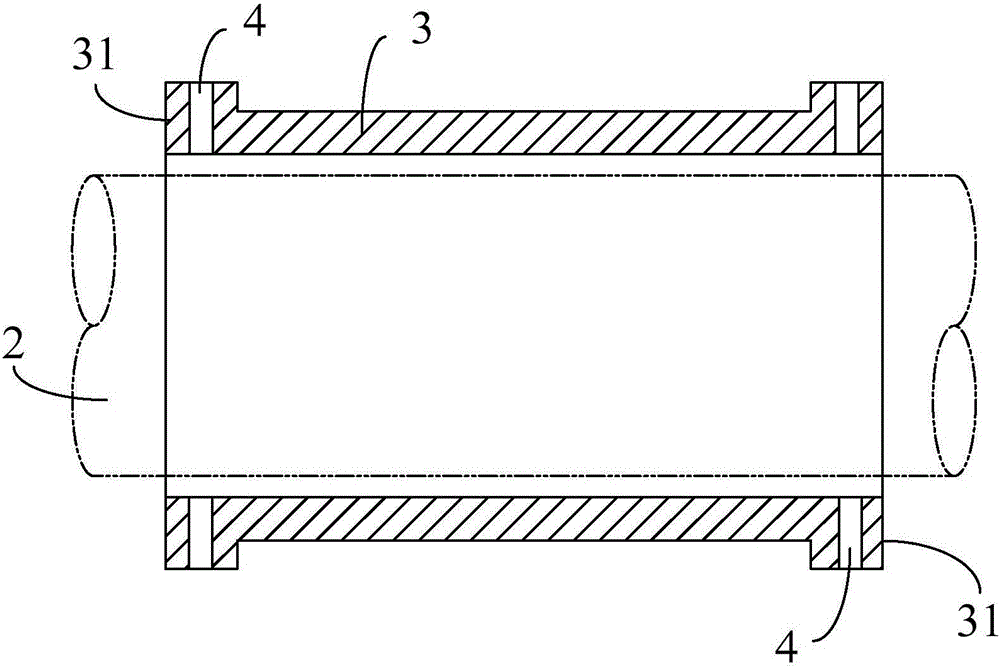

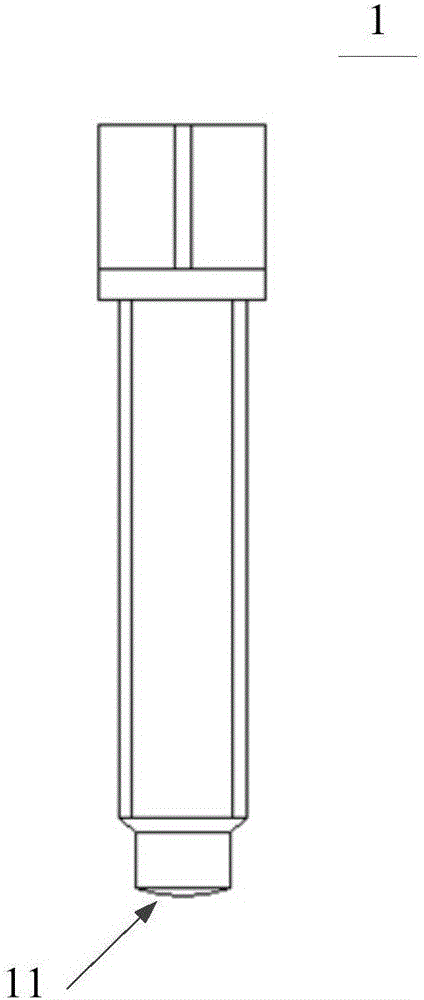

[0025] A processing tool suitable for shaft workpieces provided by an embodiment of the present invention, such as figure 1 As shown, the processing tooling includes: a plurality of adjusting bolts 1, a shaft sleeve 3 for being set outside the shaft workpiece 2 to be processed, the inner diameter of the shaft sleeve 3 is larger than the outer diameter of the shaft workpiece 2 to be processed, and the shaft sleeve 3 Flange structures 31 are respectively provided at both ends, and the peripheral wall of flange structure 31 is provided with screw holes 4 matched with adjusting bolts 1 along the circumferential direction (see figure 2 ), the adjusting bolt 1 is inserted into the shaft sleeve 3 through the screw hole 4, and the thread length of the adjusting bolt 1 is greater than the wall thickness of the flange structure 31. During processing, the shaft sleeve 3 is fixedly installed on the shaft to be processed On the outside of the workpiece 2, the center frame used to support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com