D shaft sleeve drilling pneumatic full-automatic positioning and clamping equipment of industrial sewing machine

An industrial sewing machine, positioning and clamping technology, which is applied in the direction of metal processing equipment, positioning devices, metal processing machinery parts, etc., can solve the problems of complex manual clamping methods, rising failure rate, and easy falling off of workpieces, etc., and achieve good clamping Stability, reduction of scrap rate, and shortening of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

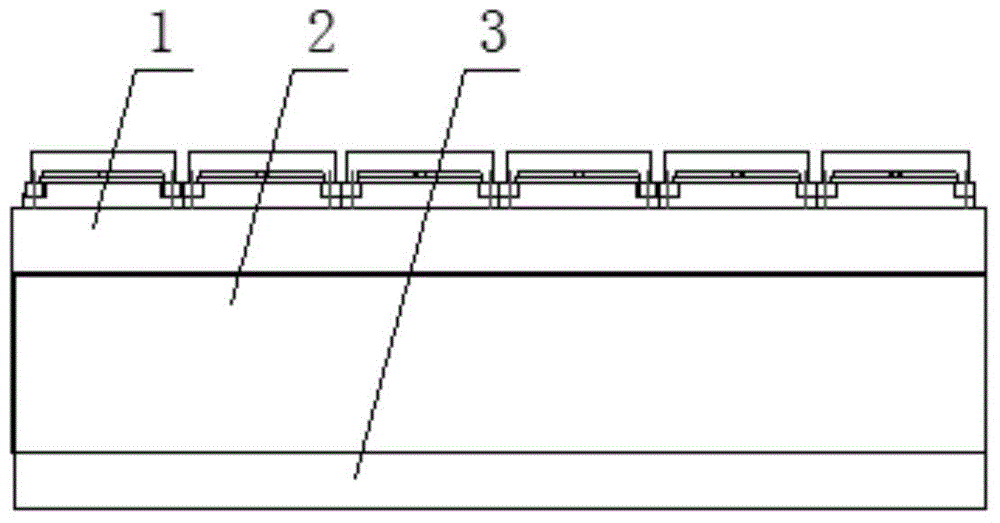

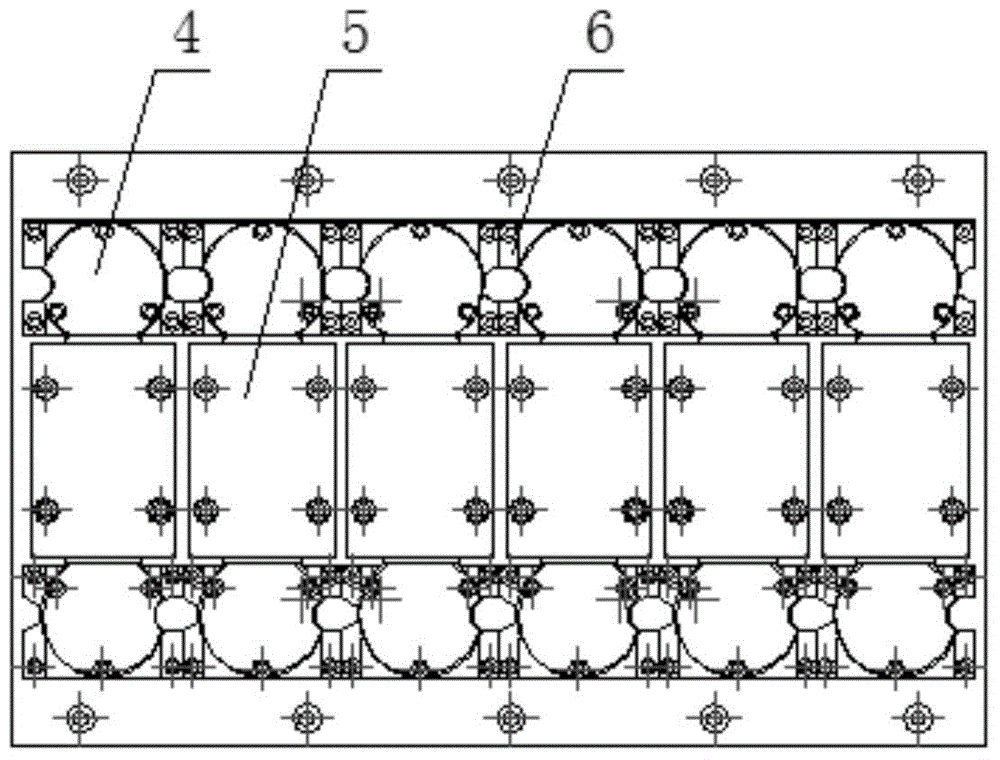

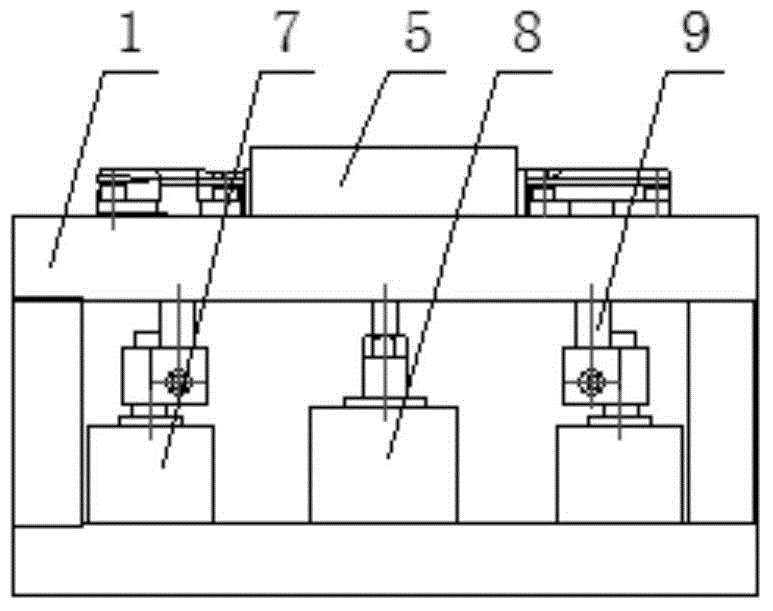

[0020] A pneumatic automatic positioning and clamping device for drilling D shaft sleeves of industrial sewing machines, including a bottom plate 3, a support plate 2, a main board 1, a clamp cylinder 8, an unloading cylinder 7 and a mounting plate 6, and the bottom plate is fixedly connected by multiple support plates motherboard. A plurality of clamp cylinders are evenly distributed on the base plate, and the clamp cylinders are arranged in a row and are all located in the middle of the base plate. The upper end of each fixture cylinder is connected with a center top block 11, and the main board is made on the main board for the opening that the center top block passes through. , the width of the upper end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com