A CNC lathe with a vacuum suction cup

A technology of CNC lathes and vacuum suction cups, which is applied in the directions of manufacturing tools, clamping, and supporting, and can solve the problems of difficult processing, difficult to fix and clamp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

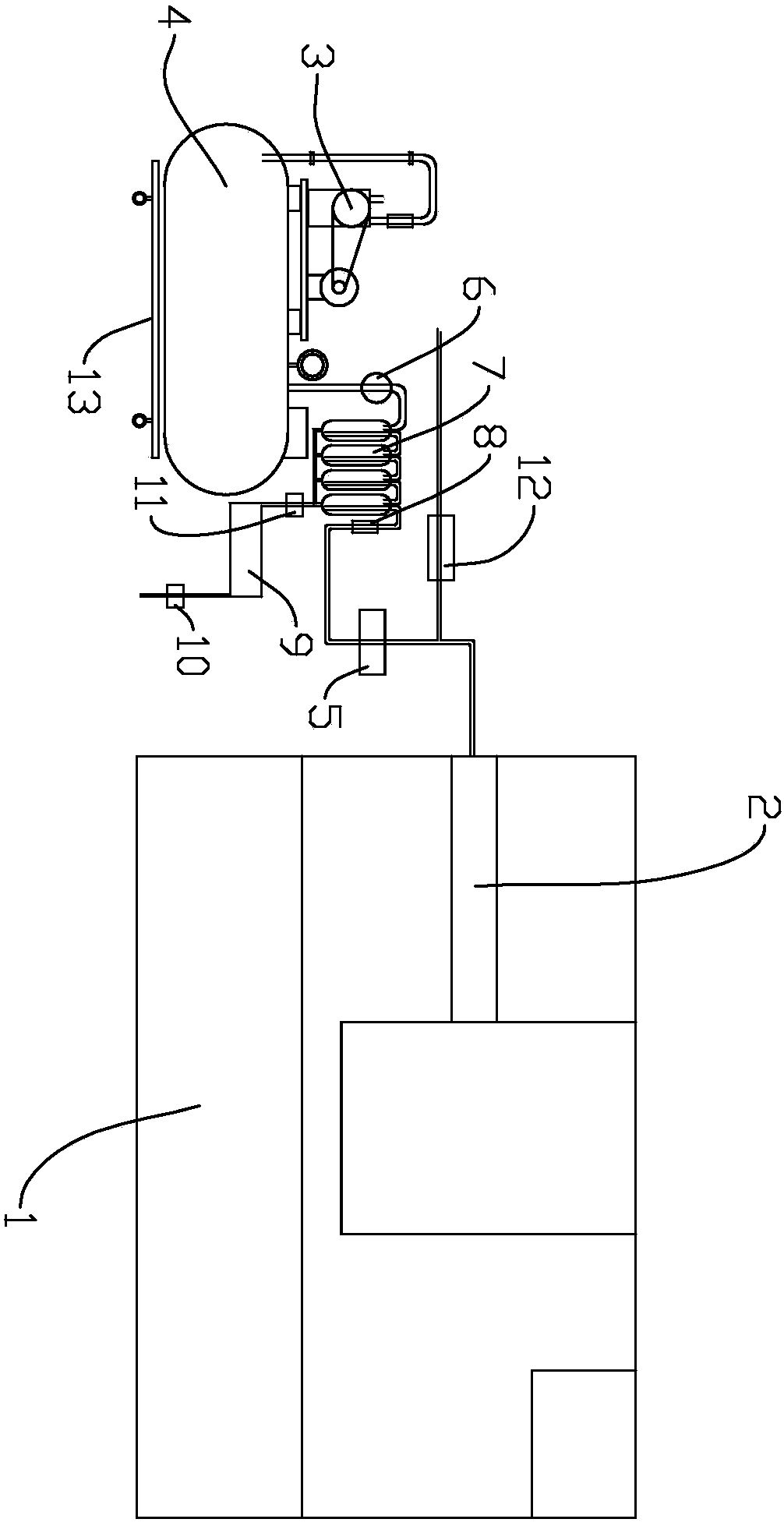

[0012] refer to figure 1 , the present invention is a kind of numerically controlled lathe with vacuum sucker, comprises frame 1 and vacuum generating device, and frame 1 is provided with main shaft 2, and the front end of main shaft 2 is provided with a suction plate, and the suction plate has a flat surface, and this suction A number of ventilation holes are arranged on the material plate, and the vacuum generating device communicates with the ventilation holes. The present invention adopting the above structure is provided with a suction plate on the main shaft 2, and a vent hole is arranged on the suction plate, and the through hole is vacuumed by a vacuum generating device, and then the sheet-type product is sucked. It can be seen that the present invention with the above structure can Thin sheet products have the effect of fixed clamping.

[0013] Such as figure 1 As shown, the vacuum generating device can specifically adopt the following embodiments, including a vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com