Roof rack for motor vehicle and manufacturing method thereof

A luggage rack and motor vehicle technology, applied to other manufacturing equipment/tools, manufacturing tools, vehicle parts, etc., can solve the problems of reducing work efficiency, consuming large steps, and consuming a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

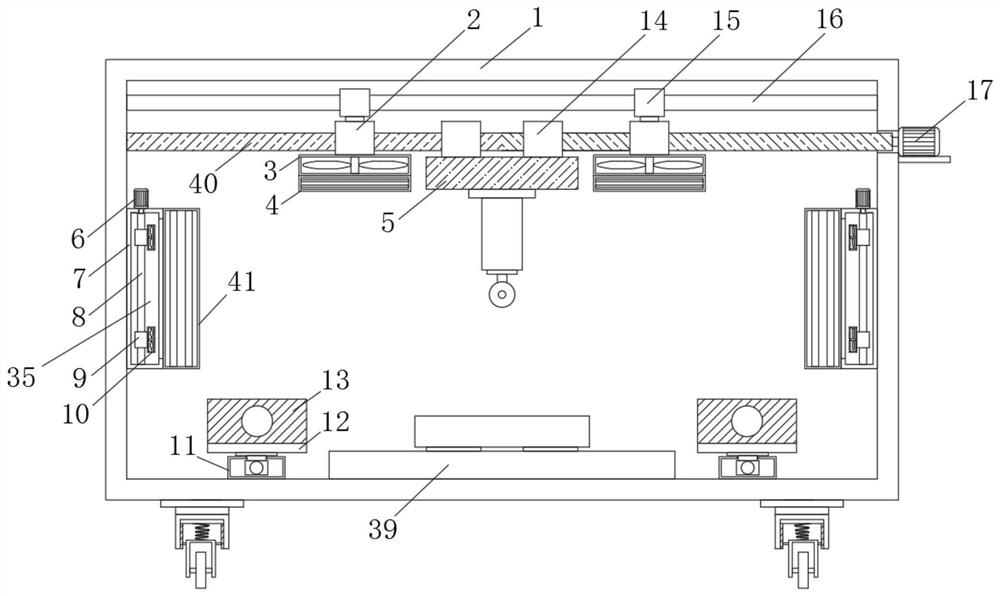

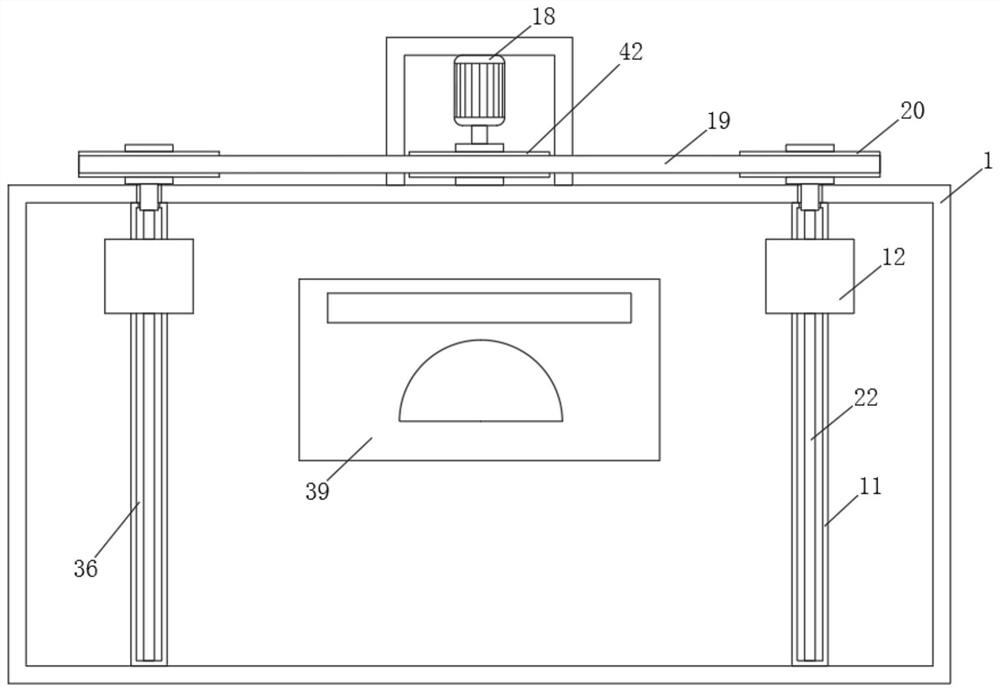

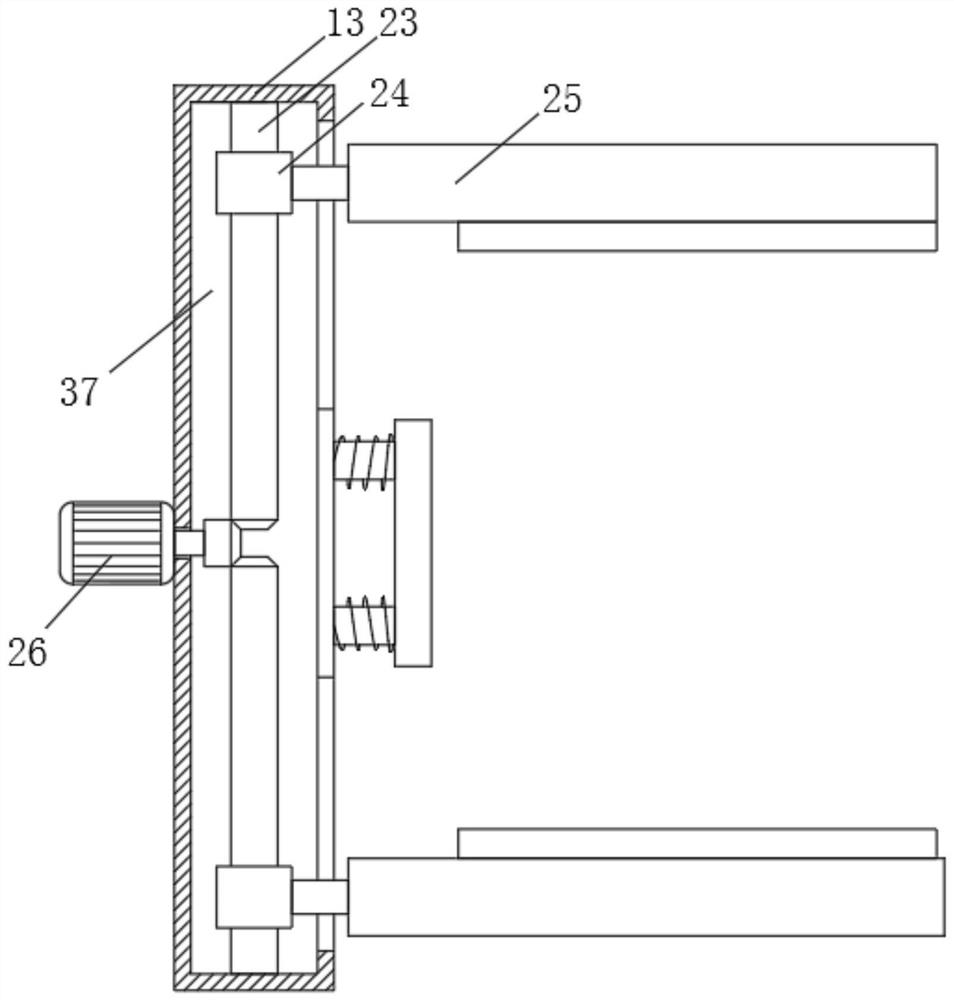

[0024] Example: such as Figure 1-5 As shown, the present invention is used for the roof luggage rack of the motor vehicle and its manufacturing method. block, both sides of the placement plate 39 are provided with sliding plates 11, the inside of the two sliding plates 11 is provided with a movable mechanism 36, and the top of the two sliding plates 11 is provided with a rotating disc 12, and the rotating disc 12 is far away from the side of the sliding plate 11. One end face is fixedly connected with the limiting shell 13, the inside of the limiting shell 13 is provided with a clamping mechanism 37, and the opposite side of the two sliding plates 11 is provided with a first fixed box 7, and the two first fixed boxes 7 A moving mechanism 35 is provided inside, and the two first fixed boxes 7 are all fixedly connected on the inner side wall of the housing 1, and the opposite ends of the two first fixed boxes 7 are fixedly connected with a dust collection box 41, and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com