A combined multi-functional mold for common sprue rods

A gate rod, multi-functional technology, applied in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of high mold development cost, unadjustable mold cavity, poor positioning effect, etc., to achieve convenient transportation and carry, reduce Development cost, the effect of improving the guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

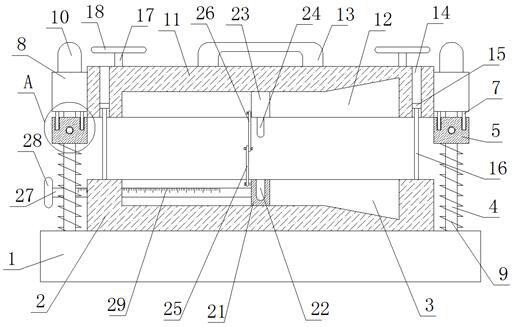

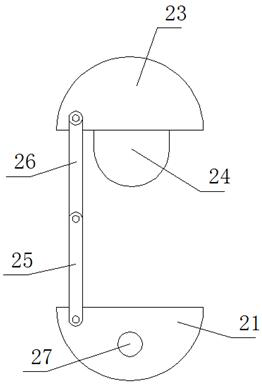

Embodiment 1

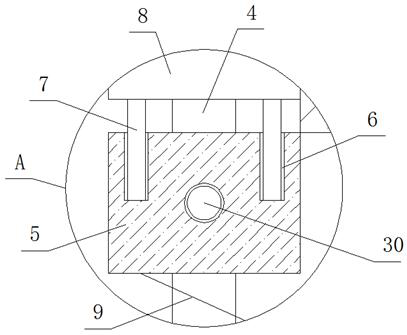

[0033] refer to Figure 1-5, a combination of commonly used sprue rod multifunctional molds, including a base 1, the top of the base 1 is fixedly connected with a lower mold body 2, the top of the lower mold body 2 is provided with a lower mold cavity 3, and the four corners of the top of the base 1 are uniform The vertical rods 4 are fixedly connected, and the four vertical rods 4 are respectively slidably provided with a slider 5 and connected with a connecting block 8, and the connecting block 8 is located above the slider 5 and is movably plugged with the slider 5. The same upper mold body 11 is fixedly connected between the four connection blocks 8, the bottom of the upper mold body 11 is provided with an upper mold cavity 12, the top of the upper mold body 11 is fixedly connected with a handle 13, and the top of the upper mold body 11 has four handles. The corners are all provided with through holes 14, and the four through holes 14 are slidingly connected with support r...

Embodiment 2

[0035] Further improved on the basis of embodiment one:

[0036] In the present invention, the tops of the four sliders 5 are symmetrically provided with two slots 6, and the insertion rods 7 are movably inserted in the eight slots 6, and the tops of the two insertion rods 7 on the same slider 5 Both extend to the top of the corresponding slider 5 and are respectively fixedly connected with the bottom of the corresponding connecting block 8, and the connecting block 8 is driven to move by pressing the upper mold body 11, and the sliding block 5 can be driven to slide at the same time.

[0037] In the present invention, one side of the four vertical rods 4 is sleeved with springs 9, and the two ends of the four springs 9 are fixedly connected to the top four corners of the lower mold body 2 and the bottom of the corresponding slider 5 respectively. The spring 9 can reset the slide block 5 .

[0038] In the present invention, the tops of one side of the four vertical rods 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com