A kind of low-cost ecological concrete and preparation method thereof

An eco-concrete, low-cost technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of the overall planning of coastal reclamation, poor structural performance of silt soil, waste of human and material resources, etc., to improve land utilization and construction Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

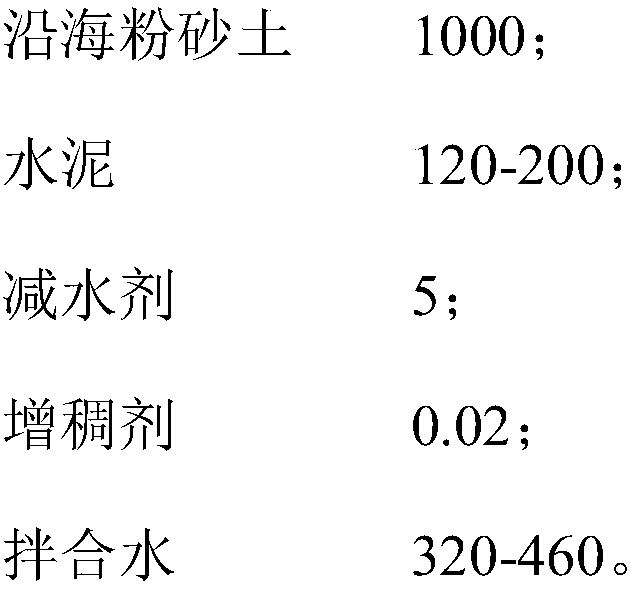

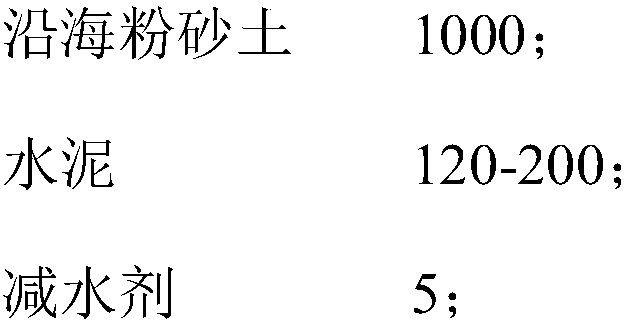

[0035] A method for preparing low-cost ecological concrete, which adopts a secondary feeding method, in which only coastal silt and mixing water are added for the first feeding, and cement, water reducer and thickener are added for the second feeding; it includes the following steps ,

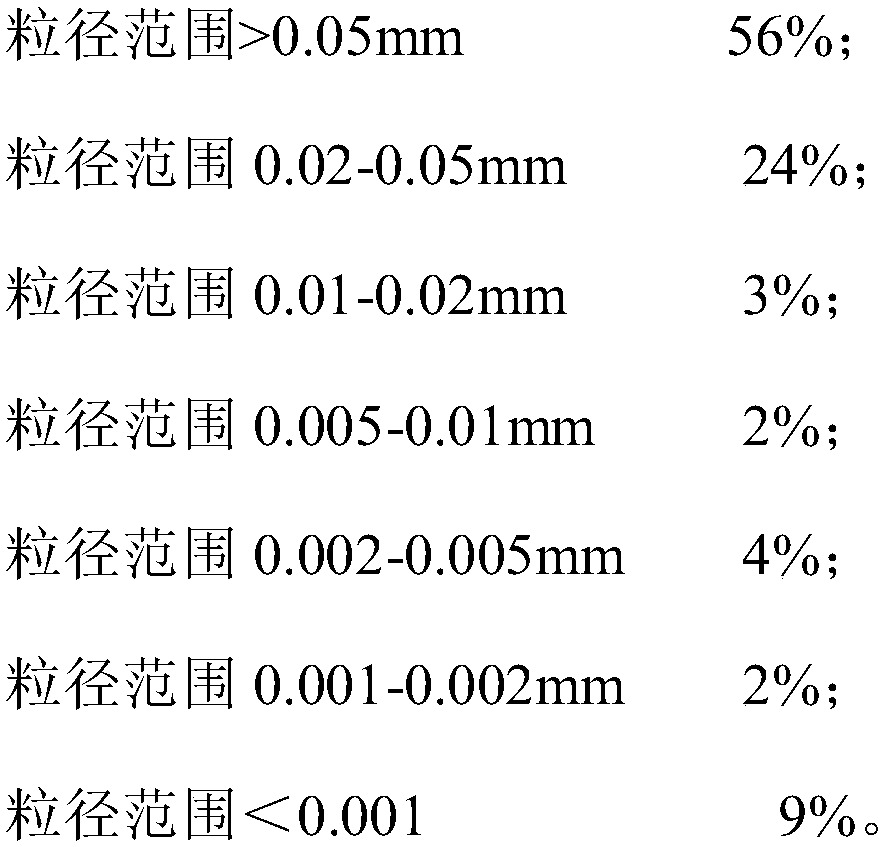

[0036] Firstly, the coastal silt soil in Dongtai City, Jiangsu Province is selected, and the coastal silt soil is configured according to the particle size mass percentage of the coastal silt sand soil.

[0037] Take 1000Kg of coastal silt soil and 320Kg of mixing water, put them into a mixer and stir for 1min to fully break and liquefy the silt soil;

[0038] Add 120Kg of cement, 5Kg of water reducer and 0.02Kg of thickener to the fully liquefied silt slurry, and stir for 1 minute to obtain fresh cement soil;

[0039] The freshly mixed cement soil is added to the mold in three layers, each layer is vibrated 20 times with a tamping rod, and then the concrete is cured in a humid environment wit...

Embodiment 2

[0041] A method for preparing low-cost ecological concrete, which adopts a secondary feeding method, in which only coastal silt and mixing water are added for the first feeding, and cement, water reducer and thickener are added for the second feeding; it includes the following steps ,

[0042] Firstly, the coastal silt soil in Dongtai City, Jiangsu Province is selected, and the coastal silt soil is configured according to the particle size mass percentage of the coastal silt sand soil.

[0043] Take 1000Kg of coastal silt soil and 400Kg of mixing water, put them into a mixer and stir for 1min to fully break and liquefy the silt soil;

[0044] Add 180Kg of cement, 5Kg of water reducer and 0.02Kg of thickener to the fully liquefied silt slurry, and stir for 1 minute to obtain fresh cement soil;

[0045] The freshly mixed cement soil is added to the mold in three layers, each layer is vibrated 20 times with a tamping rod, and then the concrete is cured in a humid environment wit...

Embodiment 3

[0047] A method for preparing low-cost ecological concrete, which adopts a secondary feeding method, in which only coastal silt and mixing water are added for the first feeding, and cement, water reducer and thickener are added for the second feeding; it includes the following steps ,

[0048] Firstly, the coastal silt soil in Dongtai City, Jiangsu Province is selected, and the coastal silt soil is configured according to the particle size mass percentage of the coastal silt sand soil.

[0049] Take 1000Kg of coastal silt soil and 460Kg of mixing water, put them into a mixer and stir for 1min to fully break and liquefy the silt soil;

[0050] Add 200Kg of cement, 5Kg of water reducer and 0.02Kg of thickener to the fully liquefied silt slurry, and stir for 1 minute to obtain fresh cement soil;

[0051] The freshly mixed cement soil is added to the mold in three layers, each layer is vibrated 20 times with a tamping rod, and then the concrete is cured in a humid environment wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com