A kind of method for preparing dicapped glycol ether

A technology of glycol ether and ethylene glycol monoether, which is applied in the field of preparation of double-terminated glycol ether, can solve the problems of difficult regeneration of resin catalysts, low catalyst yield, selectivity and service life, etc., and achieves selectivity The effect of lifting, long catalyst one-way life, and large investment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

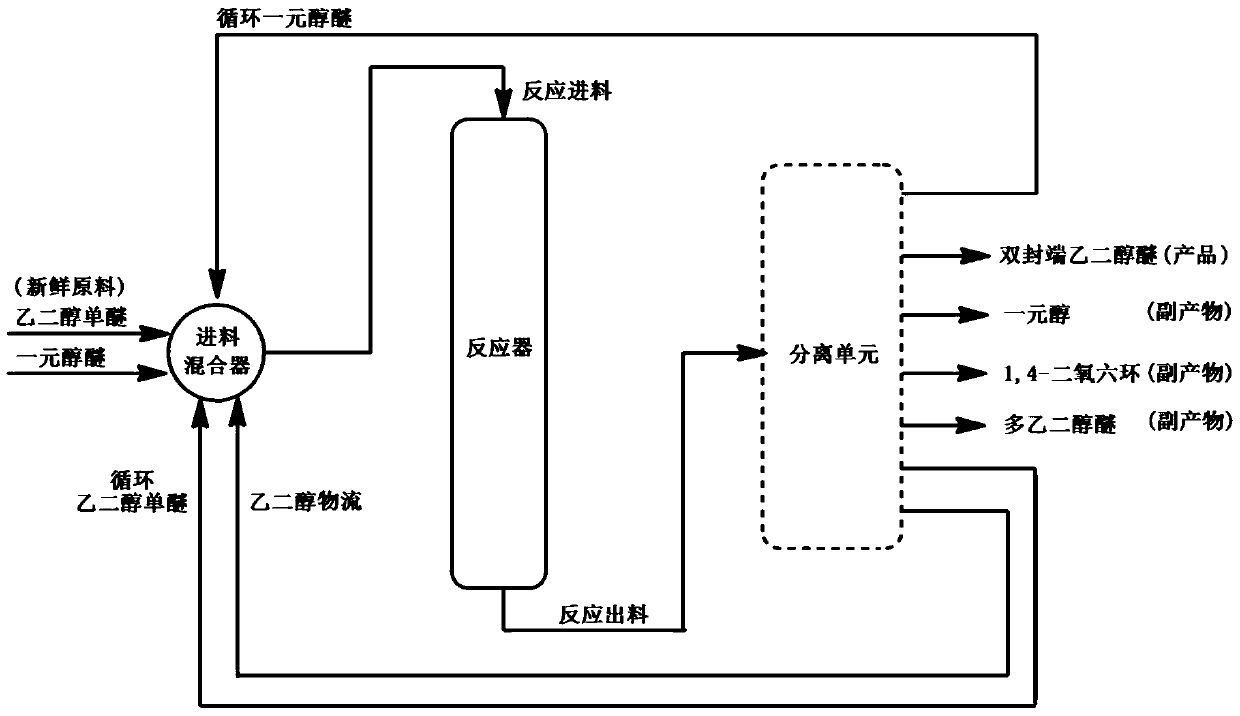

Method used

Image

Examples

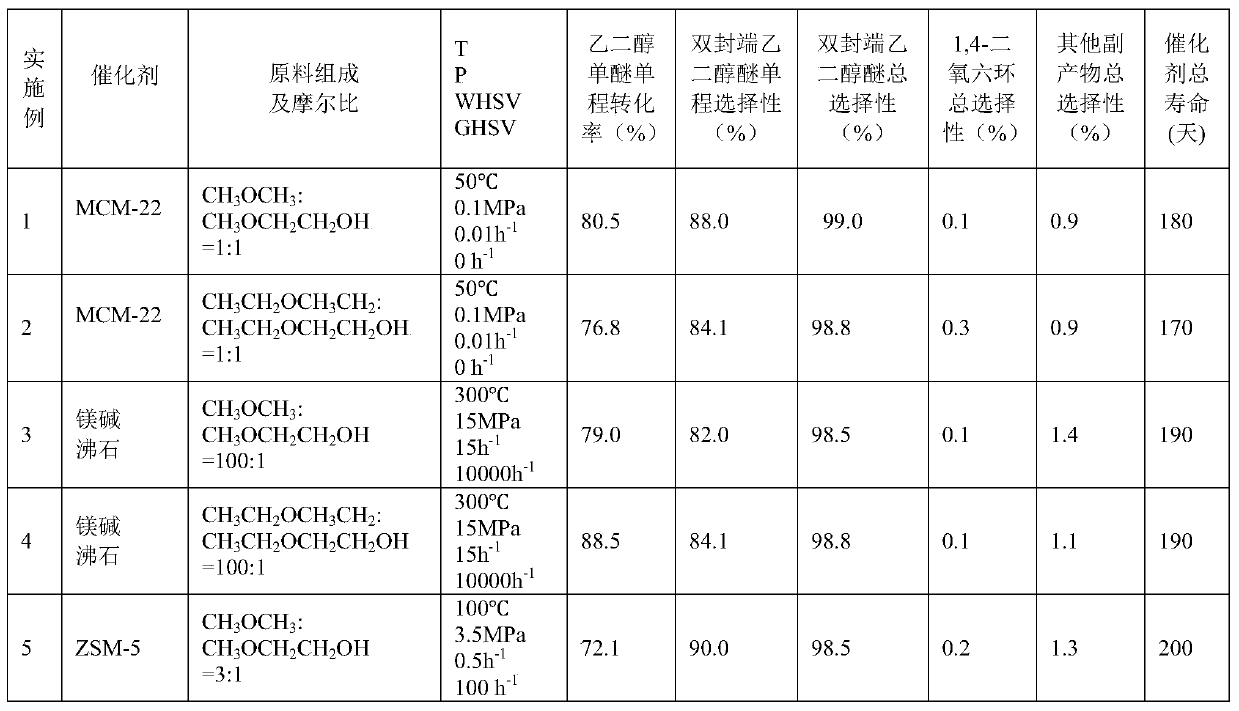

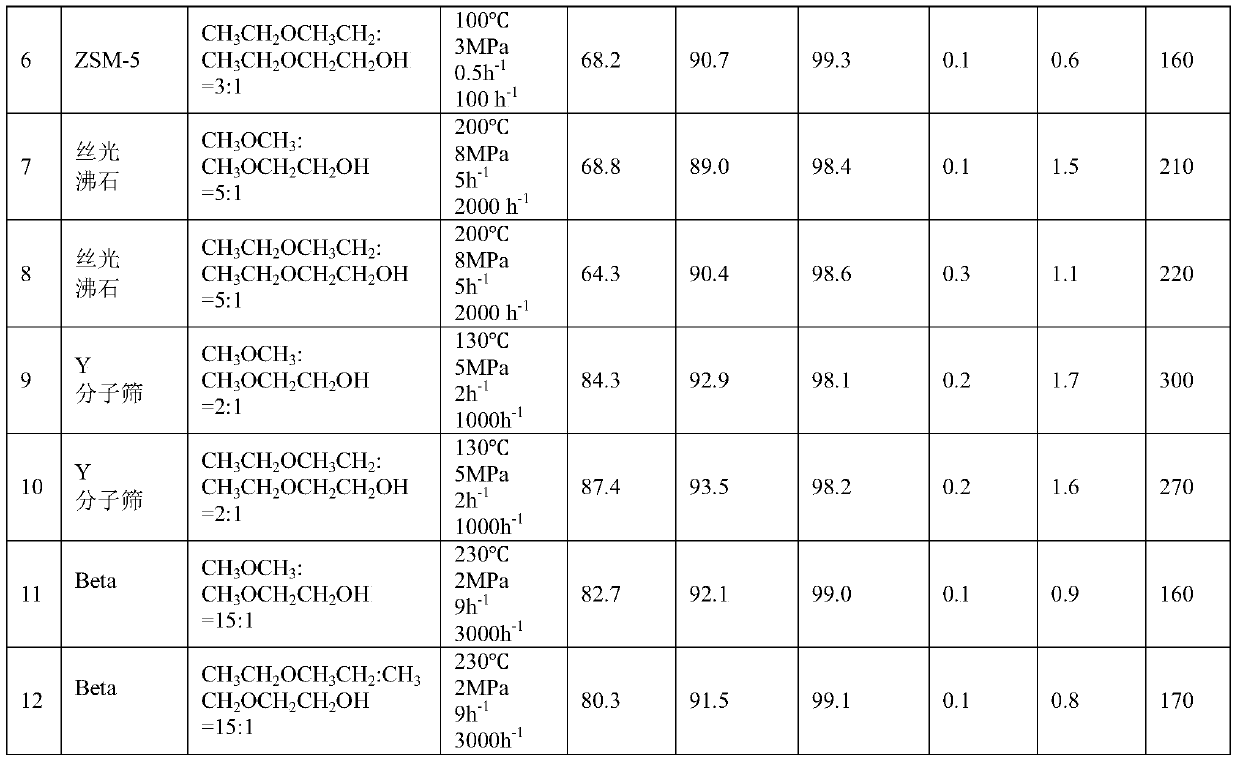

Embodiment 1

[0065] 2.0Kg of hydrogen-type MCM-22 molecular sieve catalyst with a silicon-aluminum ratio (Si:Al)=45:1 was extruded with alumina as a binder. ℃ for 5 hours to obtain a rod-shaped catalyst with a diameter of 3 mm, a length of 3 mm, and a mass content of alumina of 20%. Get 1.0Kg of this catalyst and put it into a stainless steel reaction tube with an internal diameter of 32mm, activate it with nitrogen at normal pressure and 550°C for 4 hours, then drop it to the reaction temperature (abbreviated as T)=50°C, the molar ratio of the fresh raw materials introduced for CH 3 OCH 3 :CH 3 OCH 2 CH 2 OH=1:1, reaction pressure (abbreviated as P)=0.1MPa, mass space velocity of ethylene glycol monoether in fresh raw materials (abbreviated as WHSV)=0.01h -1 , without carrier gas, after the reaction is stable, the product is analyzed by gas chromatography, and the conversion rate of ethylene glycol monoether and the single-pass selectivity of the product are calculated. Then the mon...

Embodiment 2

[0067] Raw material and mol ratio among the embodiment 1 are changed into

[0068] CH 3 CH 2 OCH 3 CH 2 :CH 3 CH 2 OCH 2 CH 2 OH=1:1, the rest of the experimental steps are consistent with Example 1. The reaction conditions and results are shown in Table 1.

Embodiment 3

[0070] The catalyzer among the embodiment 1 is changed into hydrogen type ferrierite molecular sieve, Si:Al=15:1, T=300 ℃, P=15MPa, the mol ratio of feeding raw material is

[0071] CH 3 OCH 3 :CH 3 OCH 2 CH 2 OH=100:1, WHSV=15h -1 , the carrier gas is nitrogen, the carrier gas nitrogen volume space velocity (abbreviated as GHSV) = 10000h -1 , the rest of the experimental steps are consistent with Example 1. The reaction conditions and results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com