Arc-surface modeling decorative plate installation structure

A technology for installing structures and decorative panels, which is applied in building construction, covering/lining, construction, etc., can solve problems such as stress corrosion damage, affecting unit block detail connection closing requirements, and intergranular corrosion, so as to improve installation efficiency and solve The effect of rigid adjustment problems and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

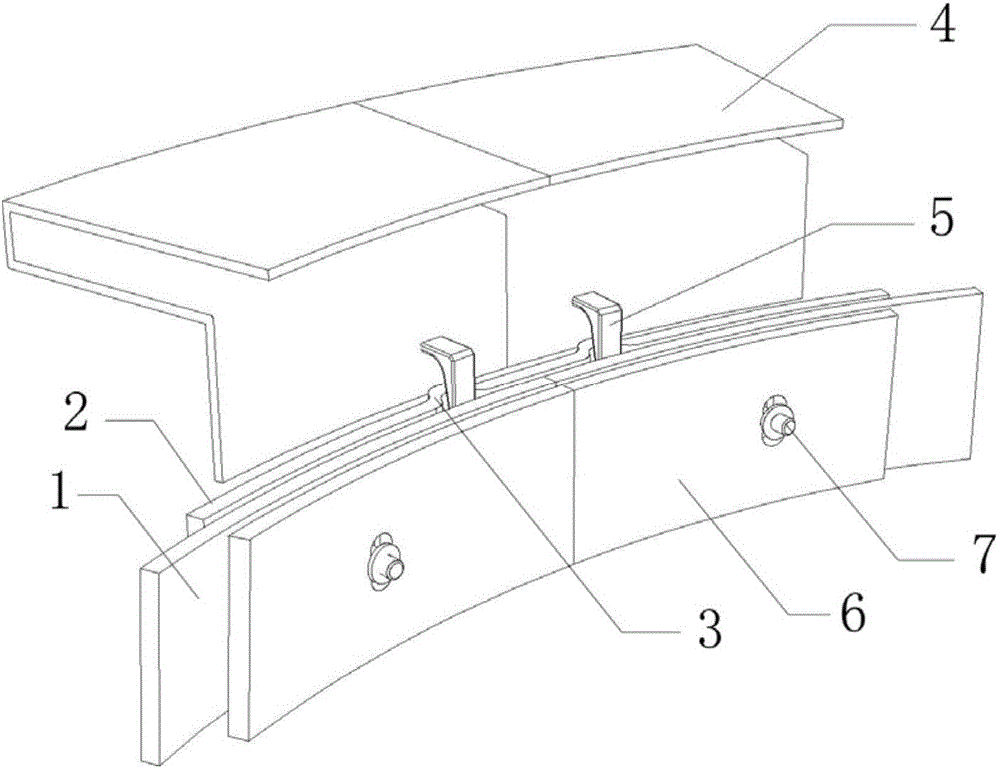

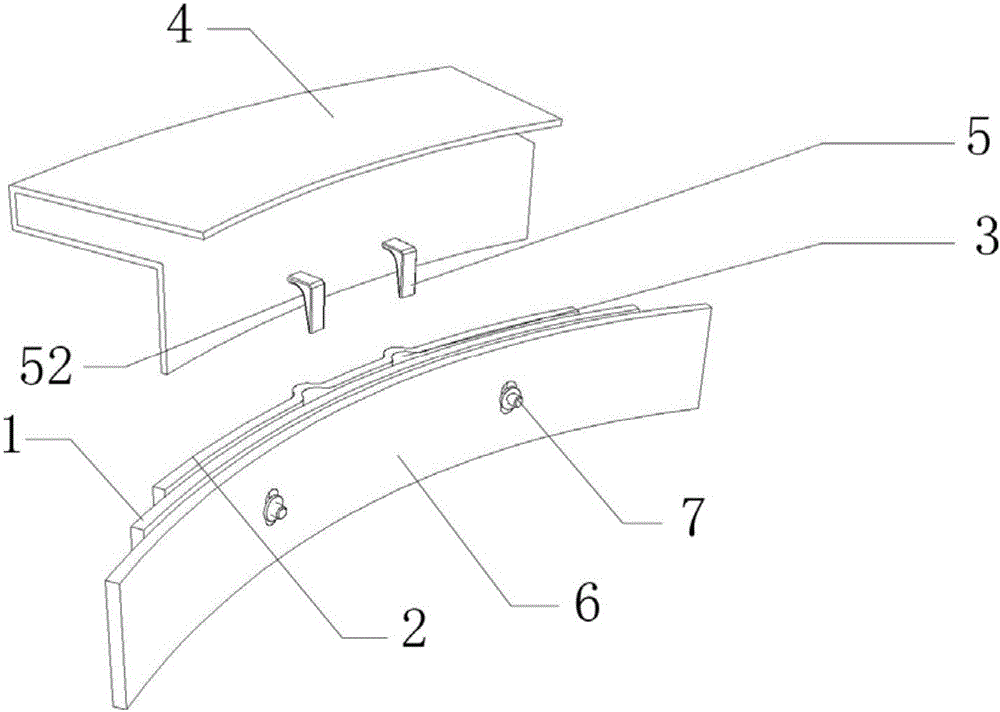

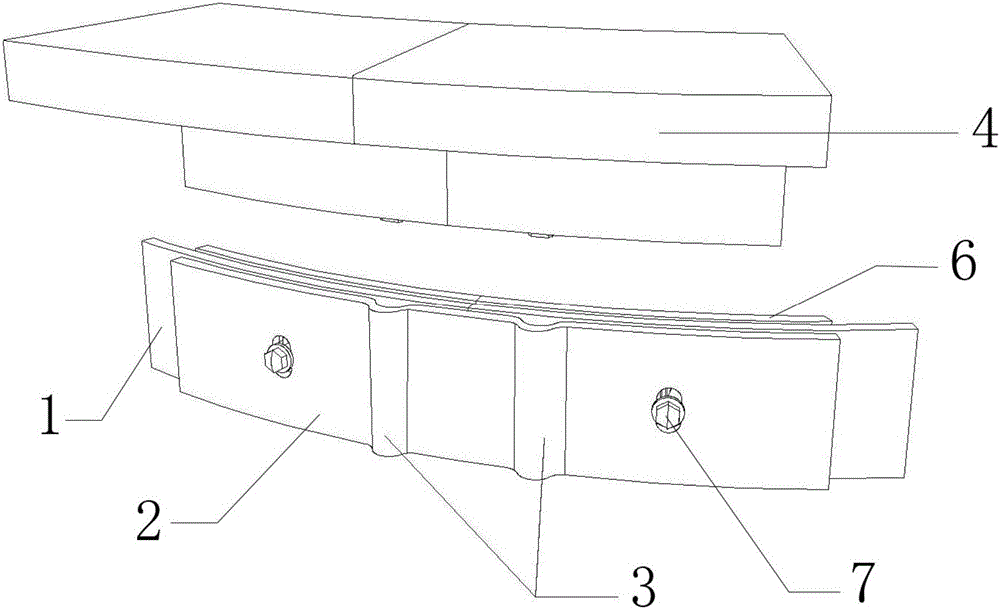

[0037] In order to achieve the purpose of the present invention, as Figure 1-5 As shown, in some embodiments of the arc-shaped decorative panel installation structure of the present invention, it includes: the base board 1, which is fixedly installed on the base frame (not shown); the surface layer installation part 2, which is fixedly connected On the base board 1, the surface installation part 2 is provided with two clamping parts 3 (one or more clamping parts 3 may also be provided, depending on the size of the surface installation part 2). The clamping surface of the clamping part 3 is provided with a first sawtooth surface 31; the surface layer unit 4 is fixedly connected with two connectors 5 (the number of connectors 5 depends on the number of the clamping parts 3), the A second sawtooth surface 51 is provided on the clamping surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com