Construction method for ultra-short-distance overlapped line tunnel long-distance guide pit advance control bursting

It is a technology of advanced control and construction method, which is applied in the direction of tunnels, earthwork drilling, mining equipment, etc., and can solve problems such as instability and damage of interlayer rock mass, uneven settlement of upper holes, and structural cracking, so as to reduce blasting vibration, Reduce the cross-sectional area and ensure the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

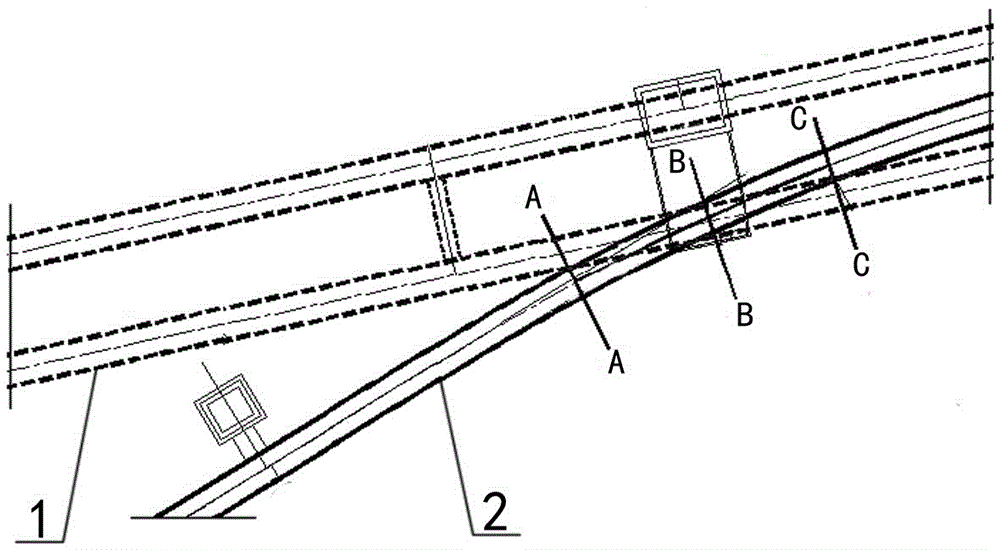

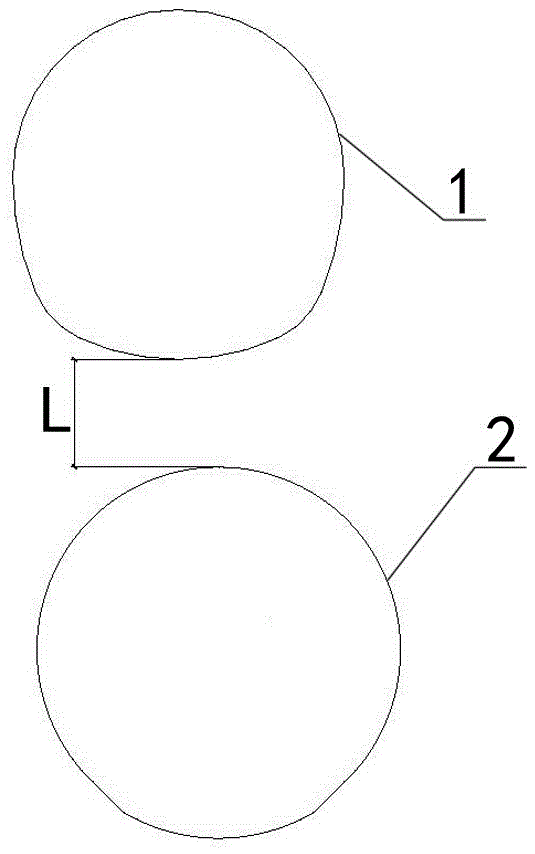

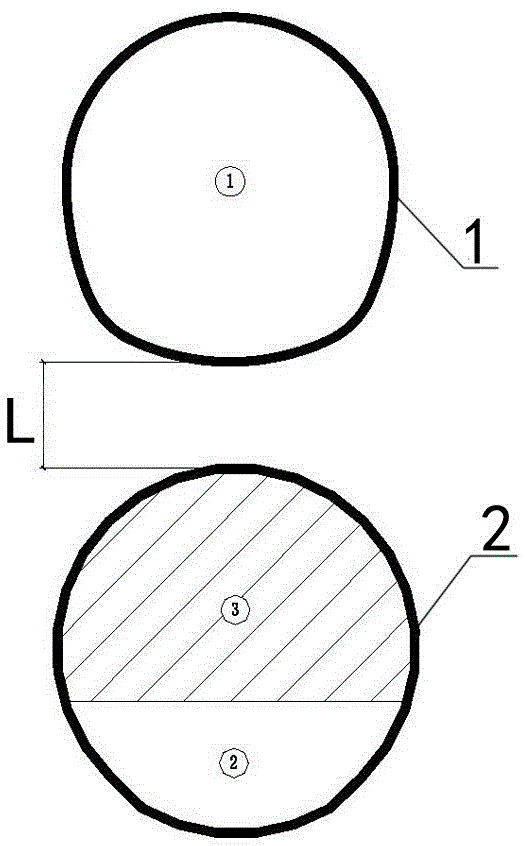

[0040] Examples see Figure 1-2 As shown in the figure, the excavated tunnel of the exit line of a certain subway project obliquely intersects with the main line tunnel, and the length of the overlapping line is about 58m. The minimum vertical distance between the exit line tunnel and the main line tunnel of the overlapping line section is 2m, that is, the thickness L of the interlayer rock mass is not less than 2m, see Figure 1-2 The position relationship diagram of the cross-section of the stacked line segment at B.

[0041] The exit line tunnel and the main line tunnel are basically in the slightly weathered mixed rock here, and the surrounding rocks of the excavation sections of the exit line tunnel and the main line tunnel are both grade III. In this embodiment, the main line tunnel is the leading tunnel 1, that is, the upper tunnel, and the exit line tunnel is the backward tunnel 2, that is, the lower tunnel.

[0042]Determining the minimum spacing of stacked tunnels ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com