Track wear automatic detection vehicle

An automatic detection and track technology, applied in measuring devices, instruments, etc., can solve the problems of high work intensity, affecting the operation safety of the conveying system, sinking of the spreader trolley, etc., to reduce labor intensity of workers, achieve high-precision quantification, reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

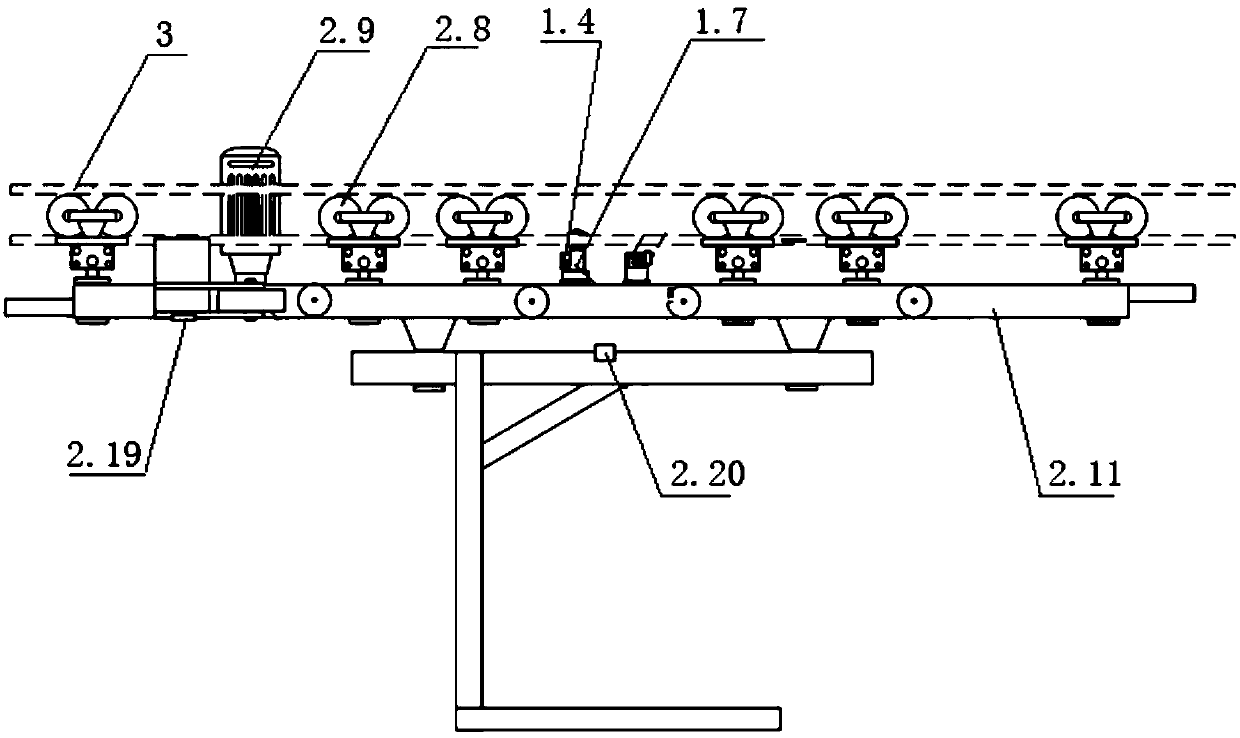

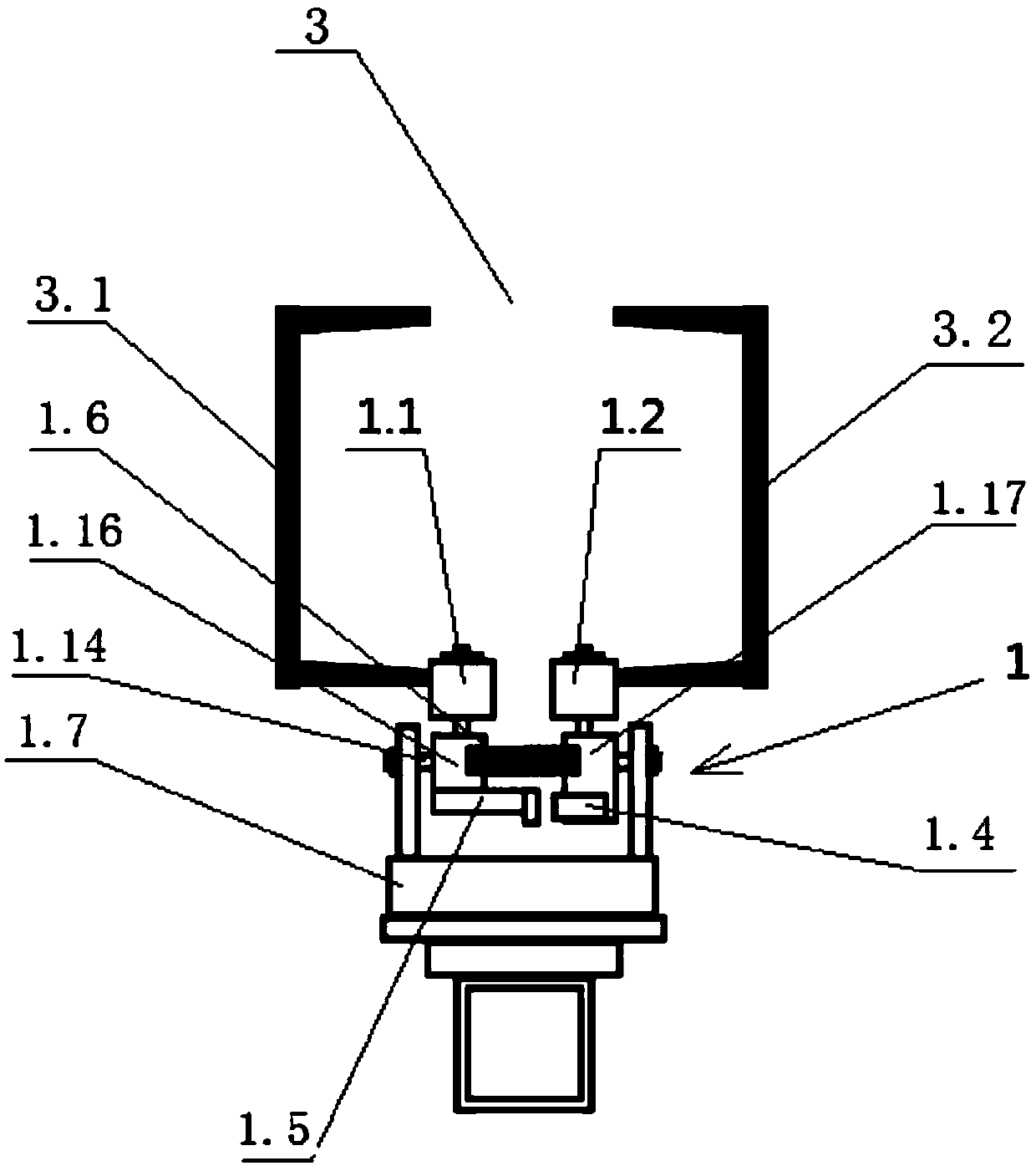

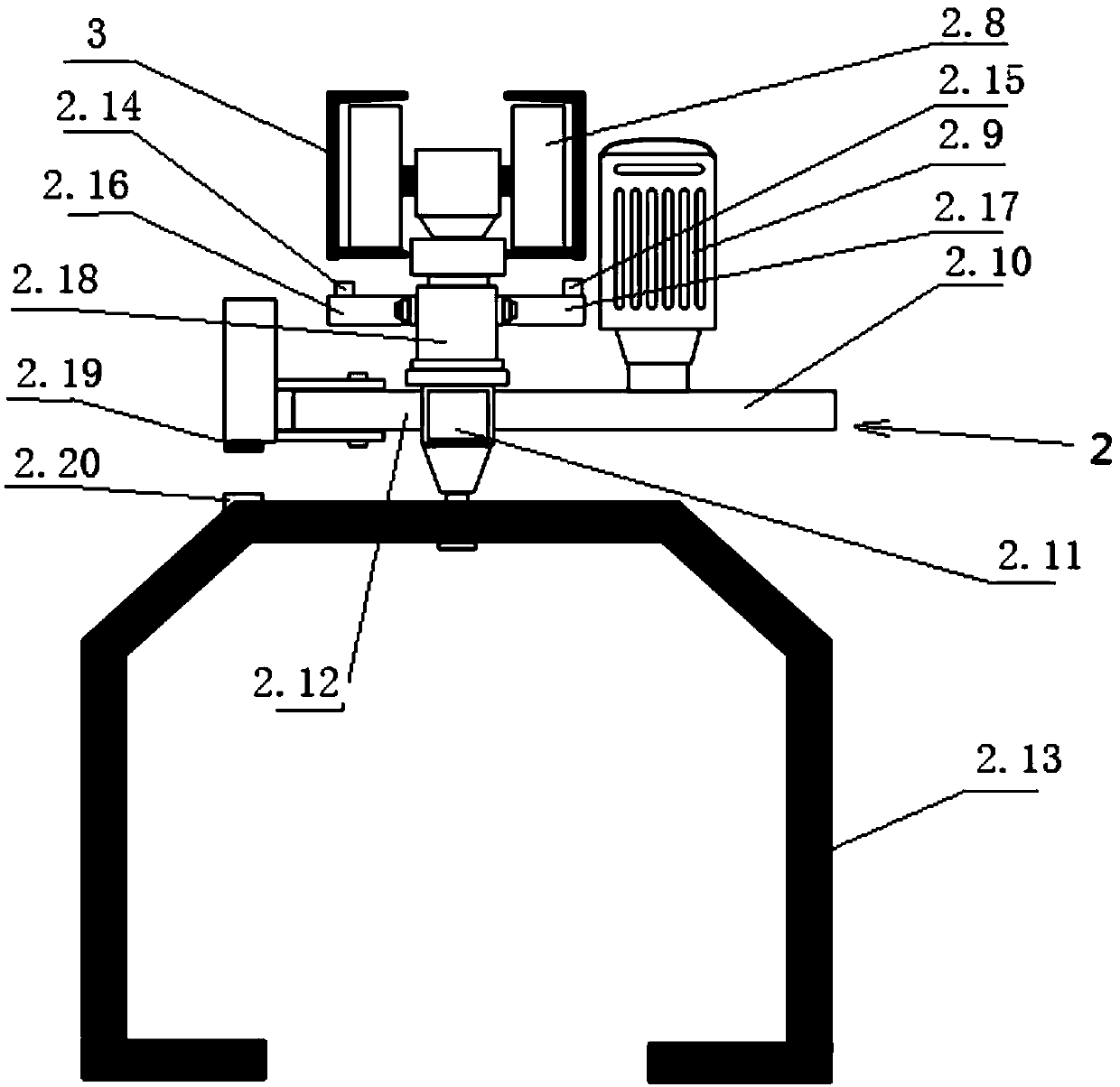

[0017] The track wear automatic detection vehicle is equipped with a track transverse gap detection device 1 and a track vertical wear detection device 2 on the track 3, and the track 3 includes a left track monomer 3.1 and a right track monomer 3.2;

[0018] The track transverse gap detection device 1 includes a first detection wheel 1.1, a second detection wheel 1.2, a displacement sensor 1.4, a detection label 1.5, a compression spring 1.6 and a mounting bracket 1.7, and there are two left and right mounting plates on the mounting bracket 1.7, Mounting shaft 1.14 is fixed on the left mounting plate and the right mounting plate of mounting bracket 1.7, and the first mounting base 1.16 is slidably installed on the mounting shaft 1.14 of the left mounting plate close to mounting bracket 1.7, and is installed near the right mounting bracket 1.7 A second mount 1.17 is slidably i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap