Ultrasonic wave flow sensor capable of adjusting acoustic reflection device

A flow sensor and reflection device technology, which is applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of not taking into account reflected waves, flow detection accuracy drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

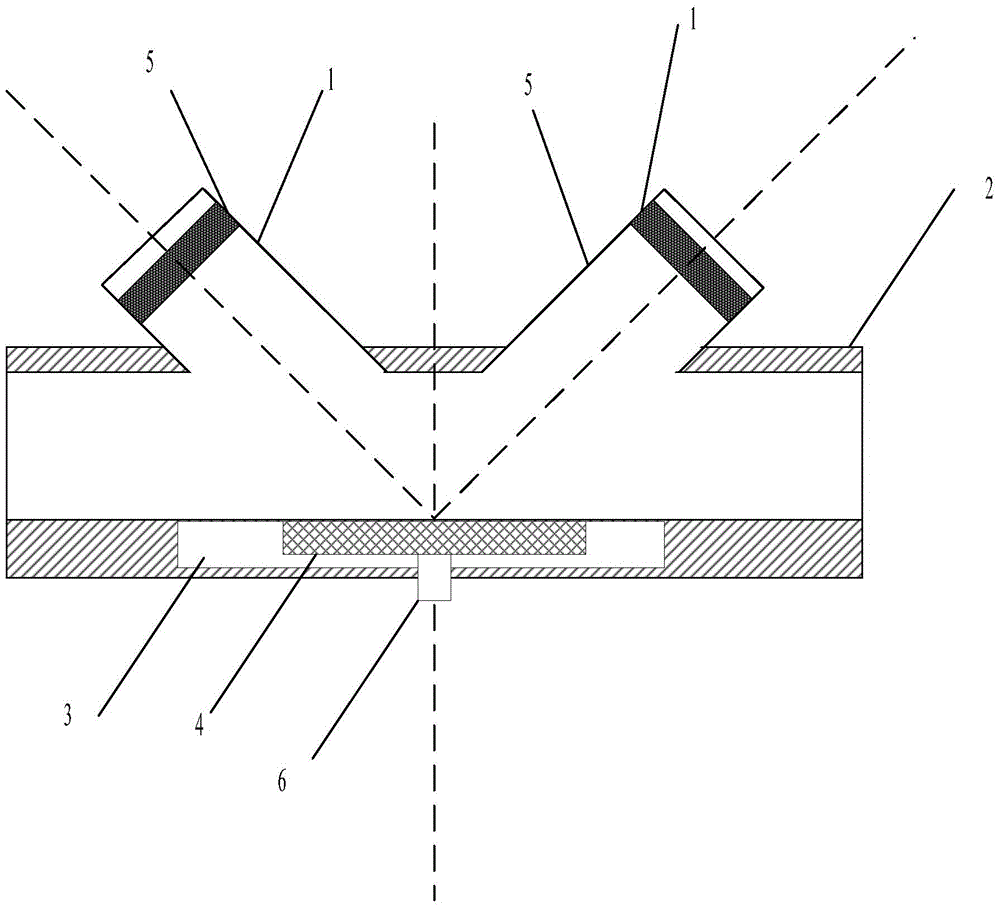

[0019] Such as figure 1 , 2 As shown in and 3, an ultrasonic flow sensor capable of adjusting the acoustic reflection device includes:

[0020] A pipe 2 with a rectangular cavity 3 is opened at the bottom;

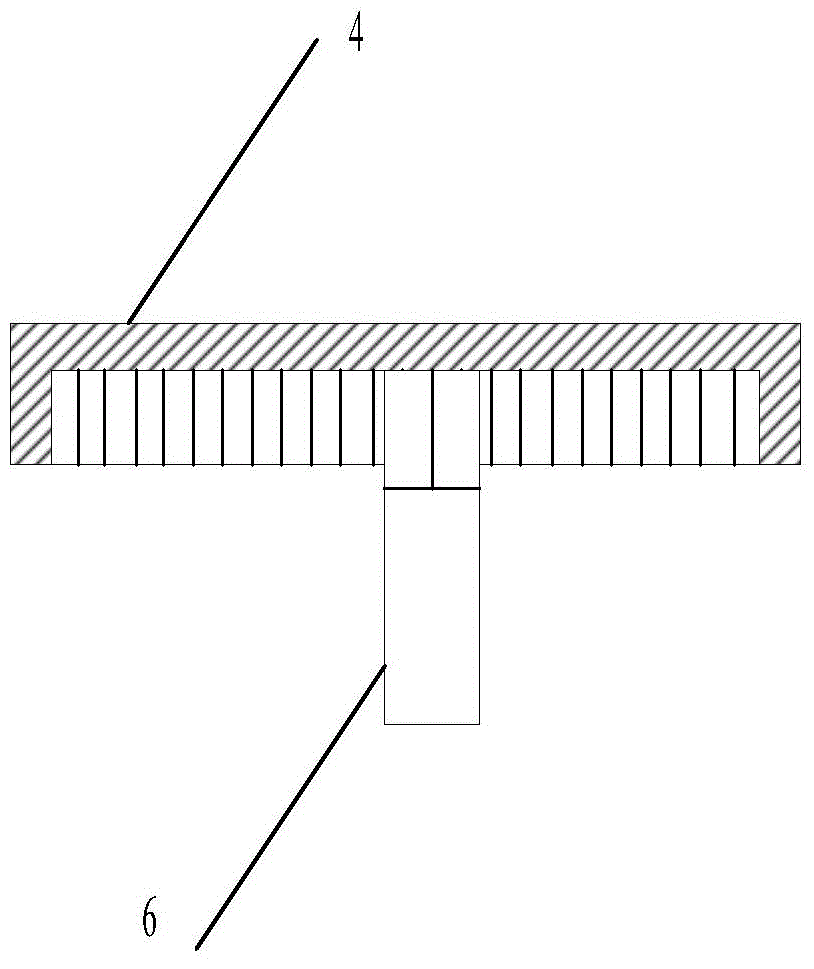

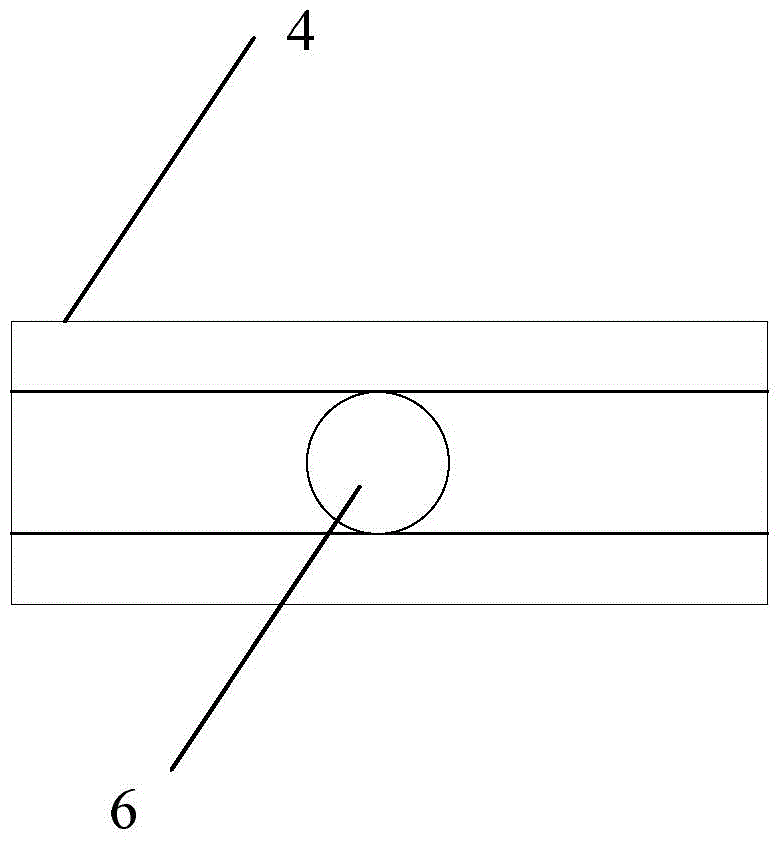

[0021] The reflecting device 4 arranged in the cavity 3, the bottom of the reflecting device 4 is provided with a rotating shaft 6, the rotating shaft 6 extends out of the pipe, and the rotating rotating shaft 6 can make the reflecting device 4 horizontally move left and right inside the cavity 3;

[0022] The thickness of the reflecting device 4 satisfies 8n+3*λ / 16≤d / cosα≤8n+5*λ / 16, where d is the thickness, α is the ultrasonic incident angle, and λ is the longitudinal wave wavelength of the ultrasonic wave in the tube wall medium, n is a natural number 0, 1, 2······;

[0023] Two symmetrically arranged pipe arms 1, the pipe arms 1 communicate with the horizontally arranged pipe 2, and the intersection of the central axis of the pipe wall 1 is located on the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com