Cow shape measuring method and cow shape measuring system based on stereo vision technology

A technology of stereo vision and measurement method, applied in the field of animal husbandry informatization, can solve problems such as large measurement errors, inability to obtain weight data, and affect the growth of dairy cows, and achieve the effect of convenient acquisition and inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

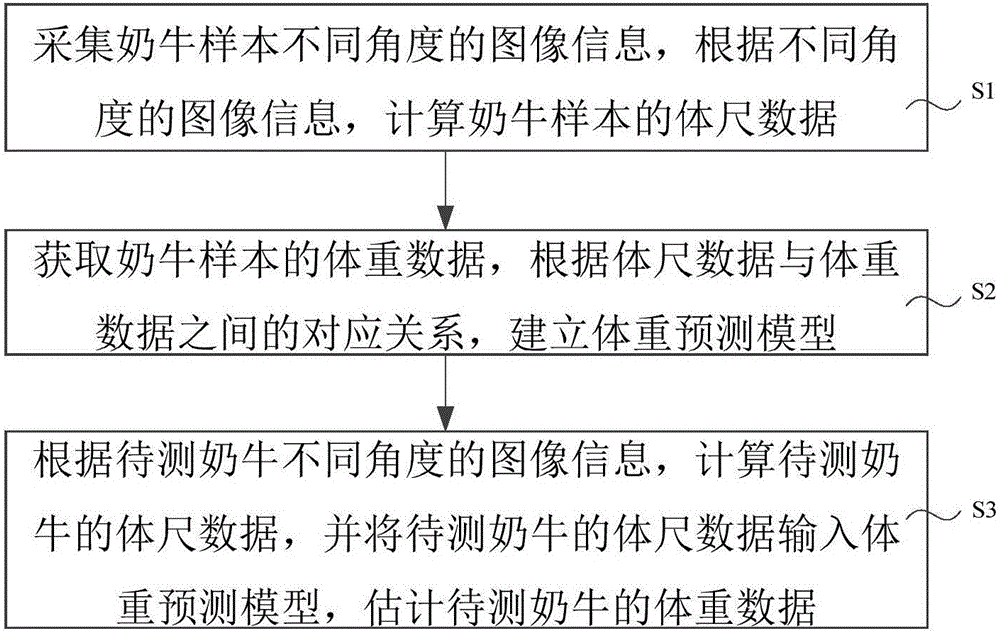

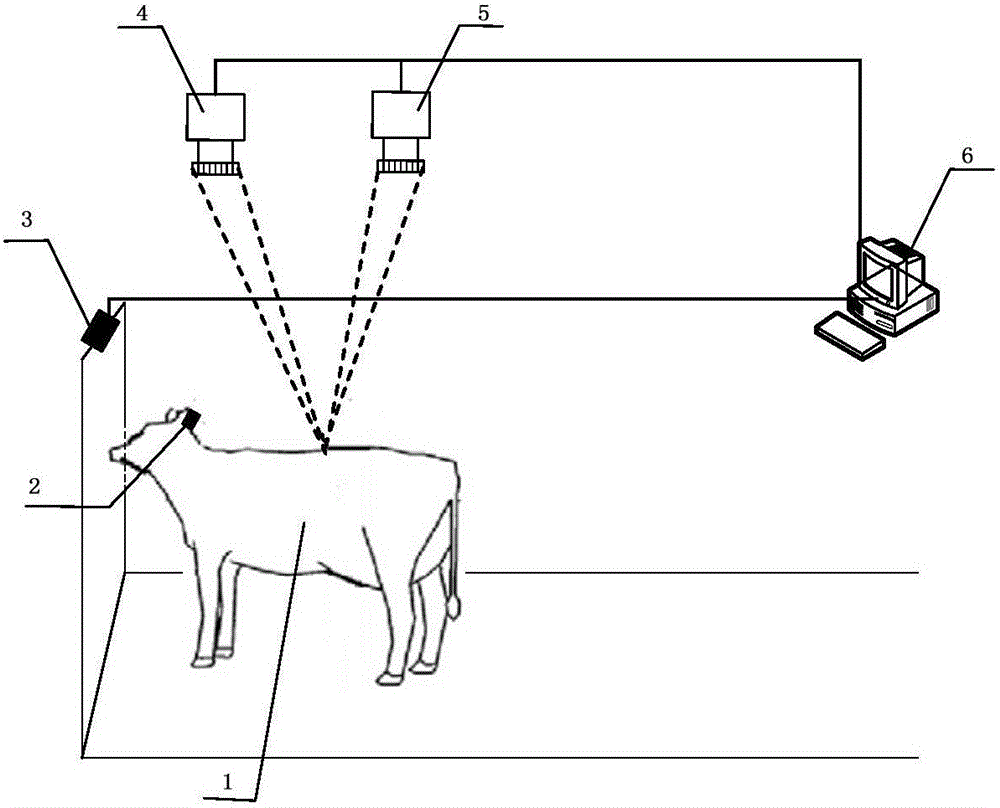

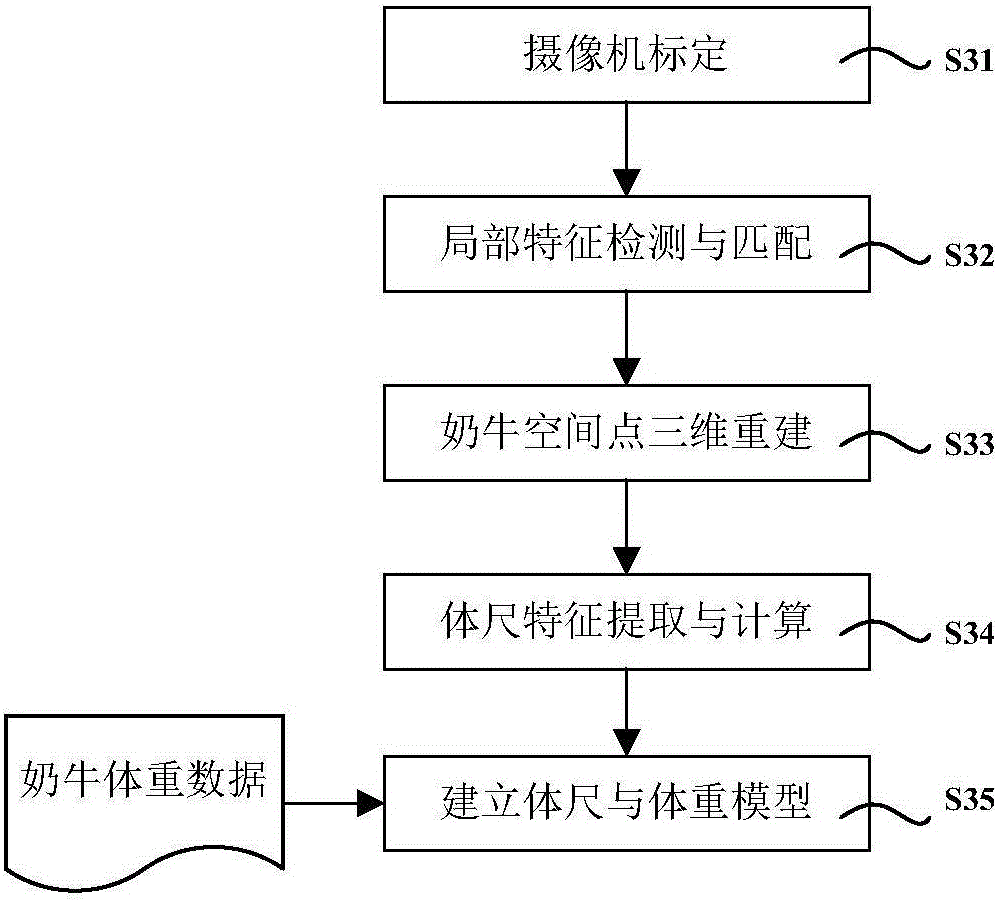

[0046] like figure 1 As shown, the present invention provides a kind of dairy cow size measurement method based on stereo vision technology, comprising:

[0047] S1: Collect the image information of different angles of the cow sample, and calculate the body size data of the cow sample according to the image information of different angles;

[0048] S2: Obtain the weight data of the dairy cow sample, and establish a weight prediction model according to the correspondence between the body size data and the weight data;

[0049] S3: Calculate the body size data of the cow to be tested according to the image information of the cow to be tested at different angles, and input the body size data of the cow to be tested into the weight prediction model to estimate the body weight data of the cow to be tested.

[0050] The dairy cow size measurement method base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com