Fuel accessory component oil leakage volume testing apparatus

A technology for a test device and fuel accessories, which is applied in the field of test devices for repairing oil leakage of fuel accessories, can solve the problems of unstable oil leakage, low troubleshooting rate, lack of oil leakage, etc. The effect of accurate oil leakage and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

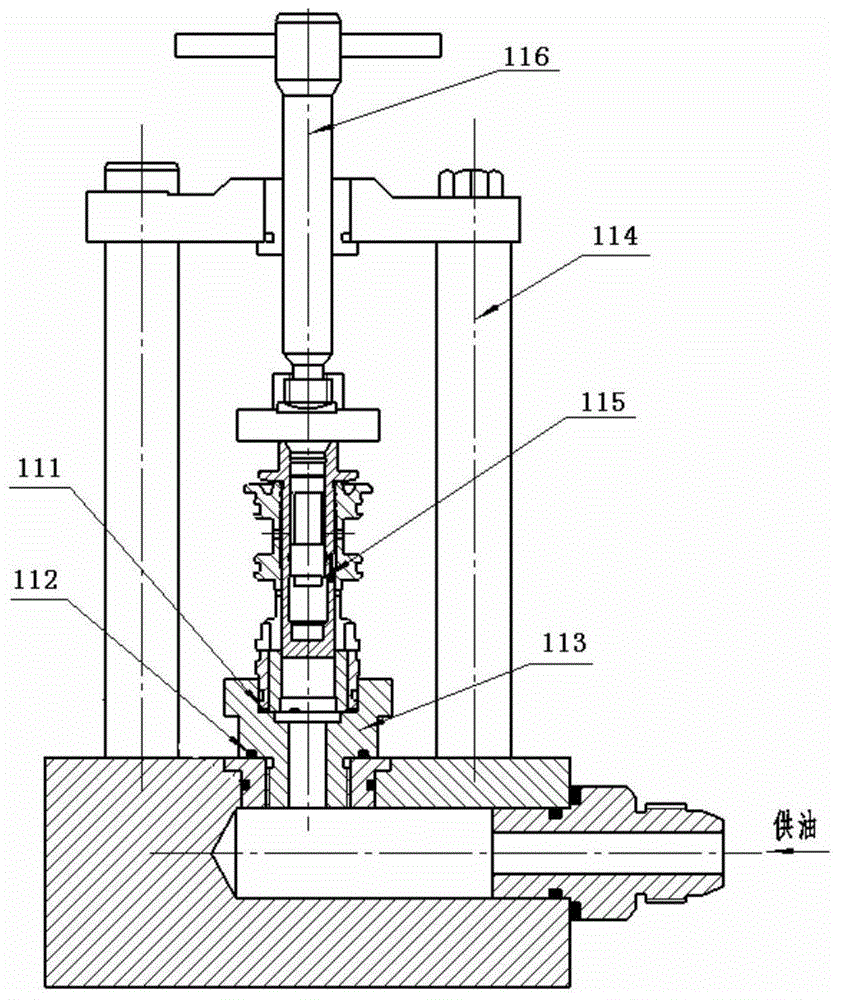

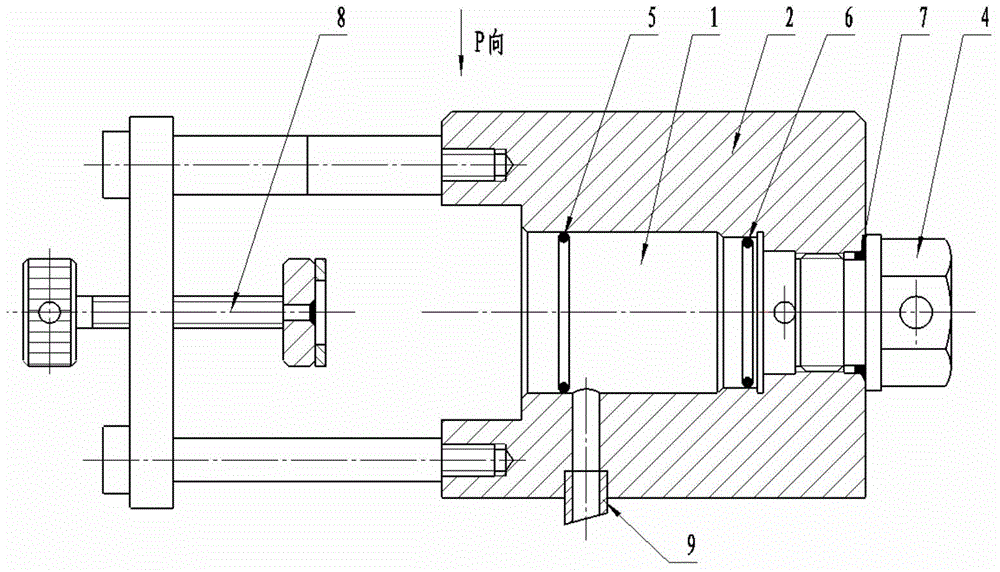

[0020] see Figure 3.1 — Figure 3.3 , the present invention according to the design technical requirements of the oil leakage test of the valve pair, track and analyze the existing test control method and process, according to the technical defects and deficiencies in the test control process, finally invented the following special oil leakage For the test device, see Figure 3.1 — Figure 3.3 Shown:

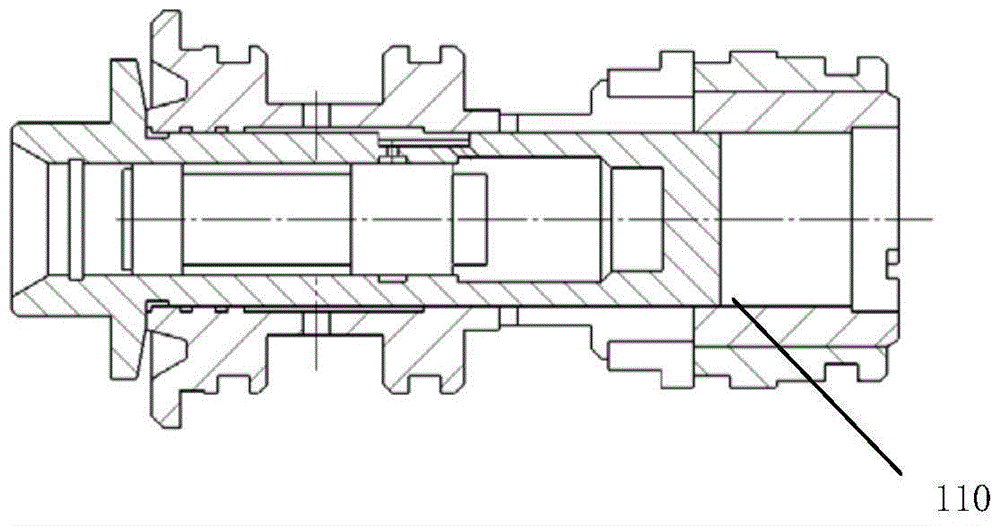

[0021] The test device includes a closed chamber 1, a closed chamber base 2 connected with the closed chamber 1, an oil inlet 3 arranged on the wall of the closed chamber and a screw plug 4 installed on the base; Rings 5 and 6; the end face of screw plug 4 is equipped with rubber ring 7; the test part, rubber ring 5, rubber ring 6, rubber ring 7, closed cavity base 2 and screw plug 4 completely seal the oil leakage site. An oil connection port 9 is arranged on the base 2 of the closed cavity, and the position of the oil connection port 9 is located between the rubber ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com