Metal mounting seat novel structure weight reduction design method used for cartridge receiver

A design method and a new structure technology, applied in the direction of computing, special data processing applications, instruments, etc., to achieve the effect of rapid design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

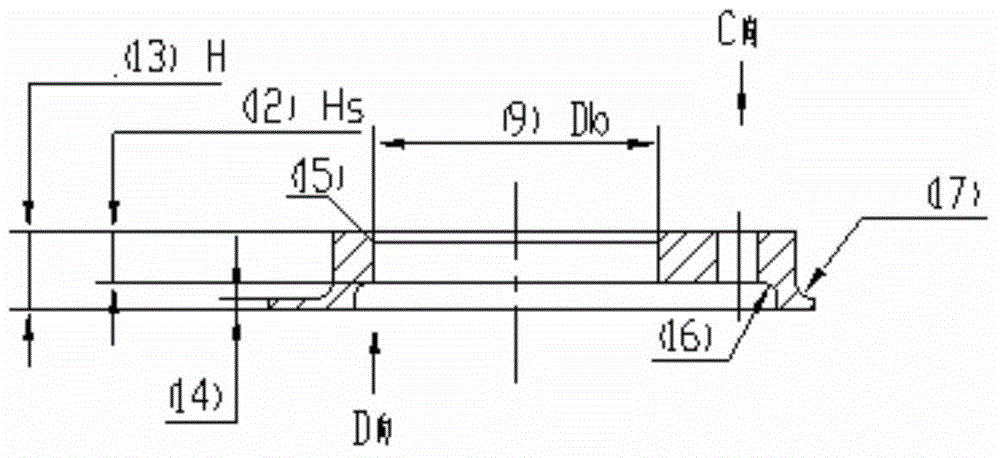

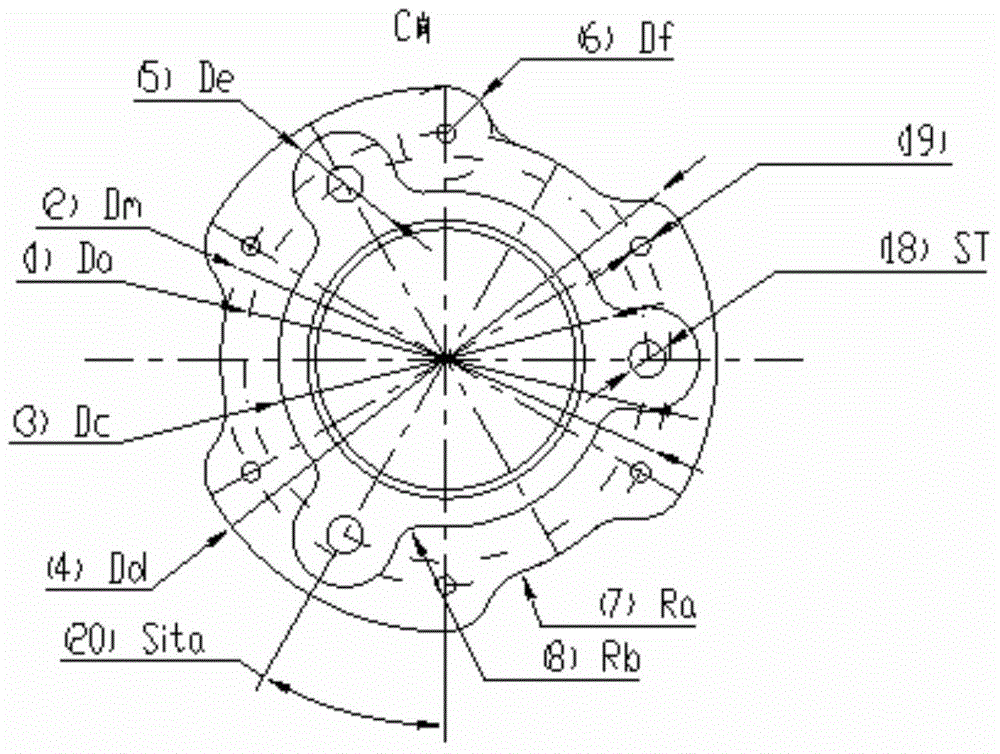

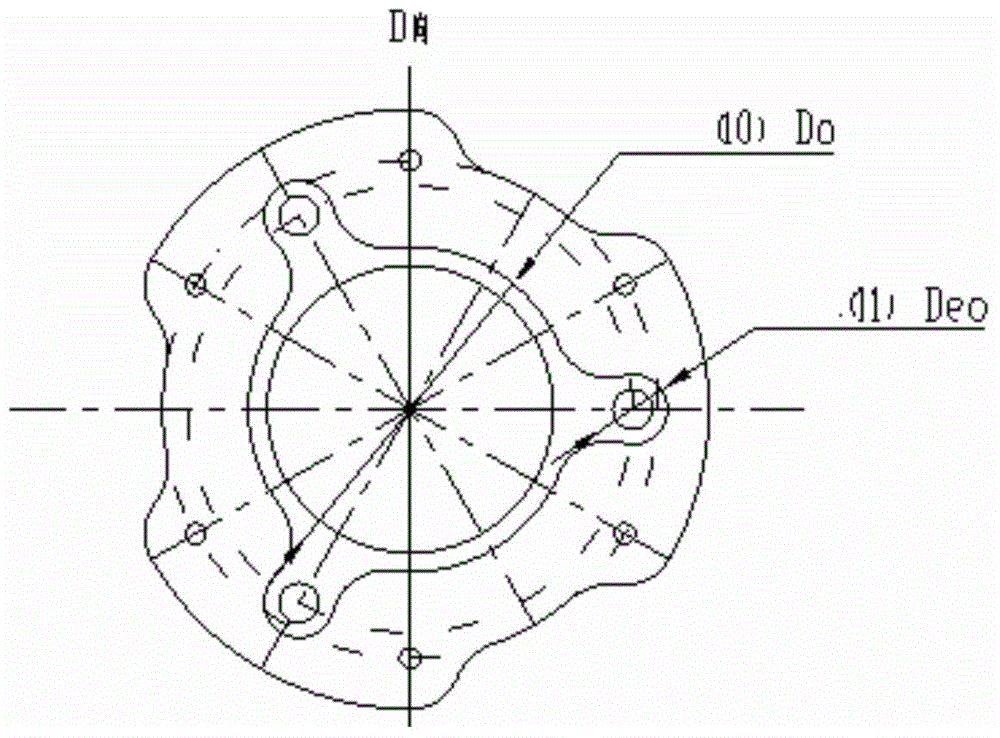

[0024] This embodiment provides a new structure weight reduction design method for a metal mounting seat for a casing, which is characterized in that: the new structure weight reduction design method for a metal mounting seat for a casing includes: the center circle of the mounting hole Diameter (1), diameter of rivet hole center circle (2), mounting seat weight reduction outer diameter (3), mounting seat outer diameter (4), mounting hole outer diameter (5), fillet (6), rounding Corner (7), rounded corner (8), inner profile diameter (9), lightening hole diameter (10), lightening hole diameter (11), mounting screw hole height (12), mounting seat height (13), Mounting seat riveting thickness (14), chamfer angle (15), fillet angle (16), fillet angle (17), internal thread hole diameter (18), rivet hole diameter (19), positioning angle (20), positioning angle (21);

[0025] The diameter of the center circle of the mounting hole (1), the diameter of the center circle of the rivet h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com