Plasma etching device for slicing wafer and method for loading and unloading wafer

An etching device and plasma technology, applied in the directions of transportation and packaging, conveyor objects, discharge tubes, etc., can solve the problems of disordered arrangement of chips and damage to films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

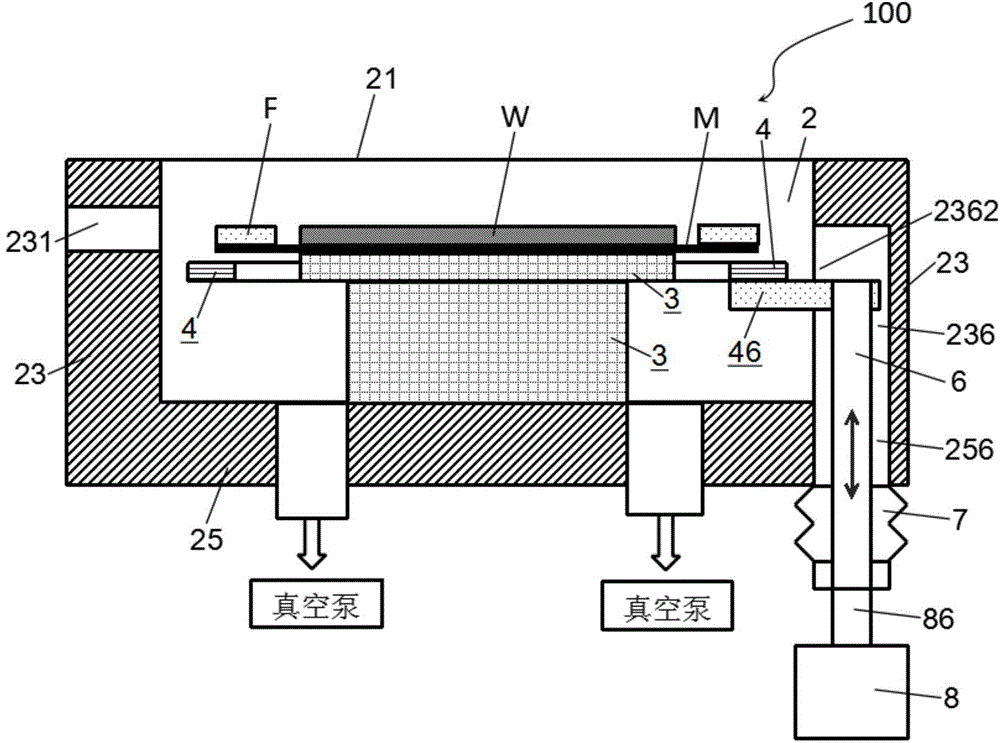

[0050] The plasma etching apparatus for wafer slicing and the method for loading and unloading wafers will be described below in conjunction with the accompanying drawings. It should be emphasized that this is only an exemplary description, and other implementations of the present invention are not excluded.

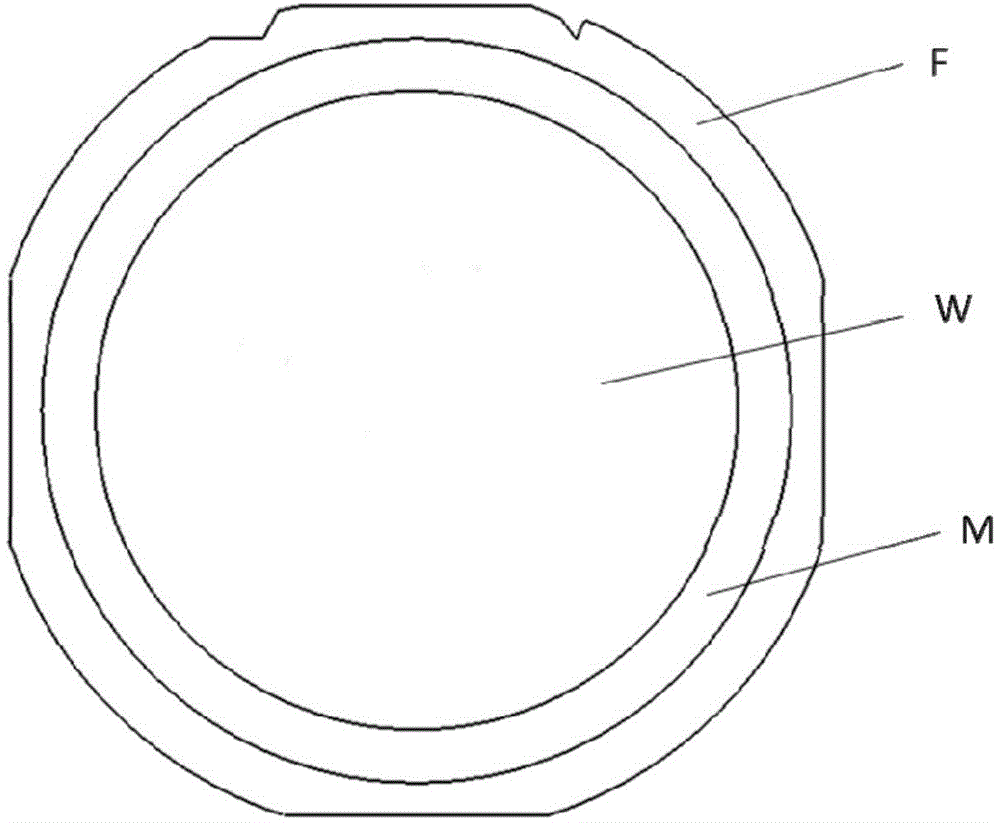

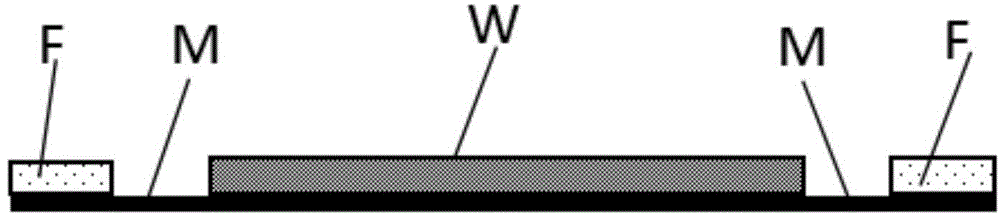

[0051] image 3 It is a schematic structural diagram of a plasma etching apparatus for wafer dicing (waferdicing) according to an embodiment of the present invention. In this device, the adhesive material between adjacent chips (or dies, DIEs) on the wafer is removed by plasma etching to form a dividing groove, so that the chips are independent of each other. In order to prevent damage to the structure of the chip itself in the process of slicing the chip, a mask layer, such as photoresist, can be coated on the surface of the chip area, and the mask layer does not cover the adhesion material between the chips. As a special slicing method, in the slicing process, the plasma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com