Insertion part

A part-integrated technology, applied in the field of one-piece surface contact plug-in parts, can solve the problems of complex process and high production cost, and achieve the effect of reducing processing cost, high safety in use and less heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

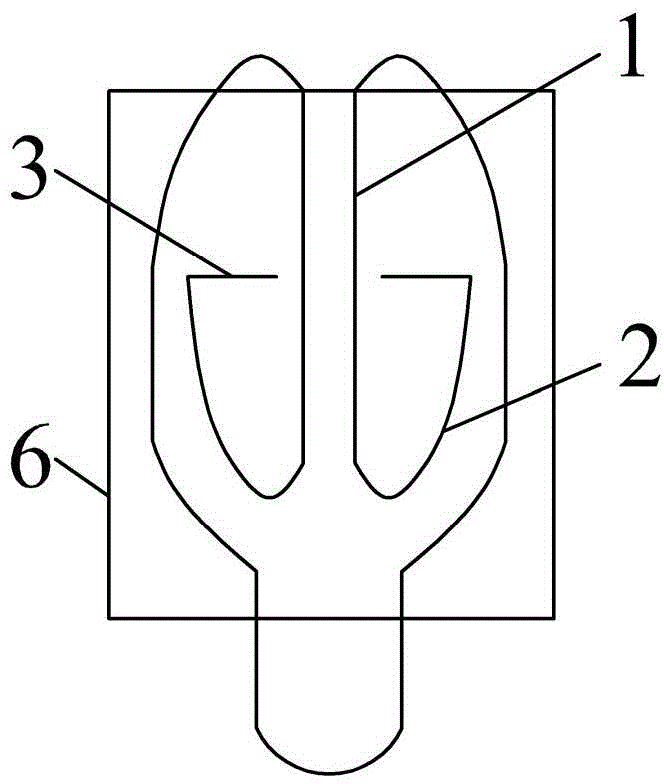

[0025] Embodiment one: see figure 2 , a plug-in component, including two oppositely arranged plate-type contact pieces 1, the lower end of the contact piece 1 is an integral structure, which can meet the torsional deformation in a small angle range, increase the stability of the contact piece; at the same time, reduce the The one-time welding with the wire improves the reliability of the contact sheet 1, and the reduction of the solder joints also reduces the contact resistance. After the two contact pieces are bent outward, they continue to extend upward and bend inwardly to form the return spring 2, and the two contact pieces have a symmetrical structure. The end of the return spring 2 is provided with a limit plate 3 perpendicular to the contact piece 1. The limit plate 3 can prevent the return spring from being over-pressed, so that the return spring is in the best state and prolongs the service life of the plug-in parts , The tops of the two contacts form a V-shaped soc...

Embodiment 2

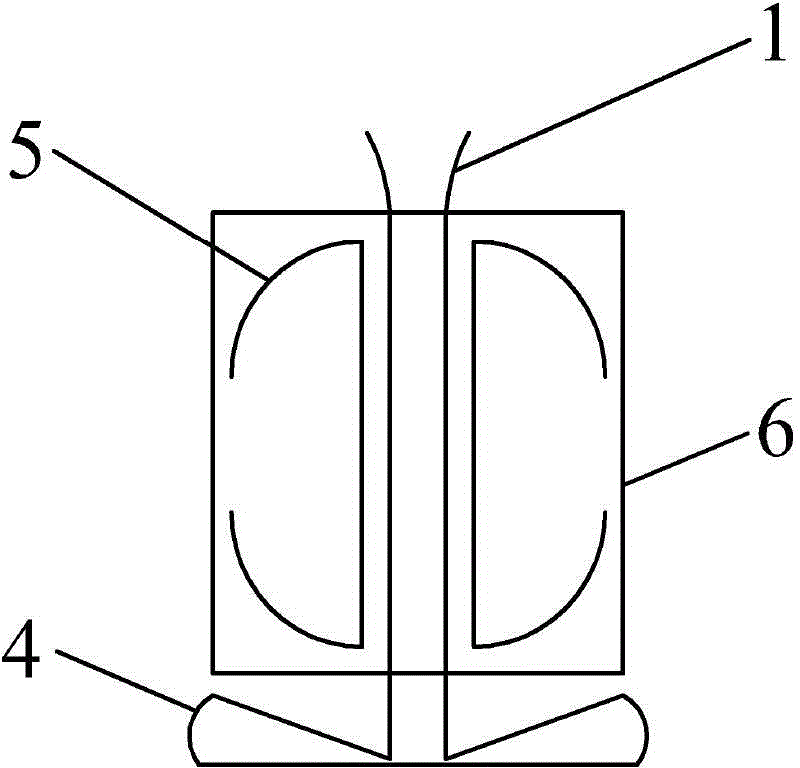

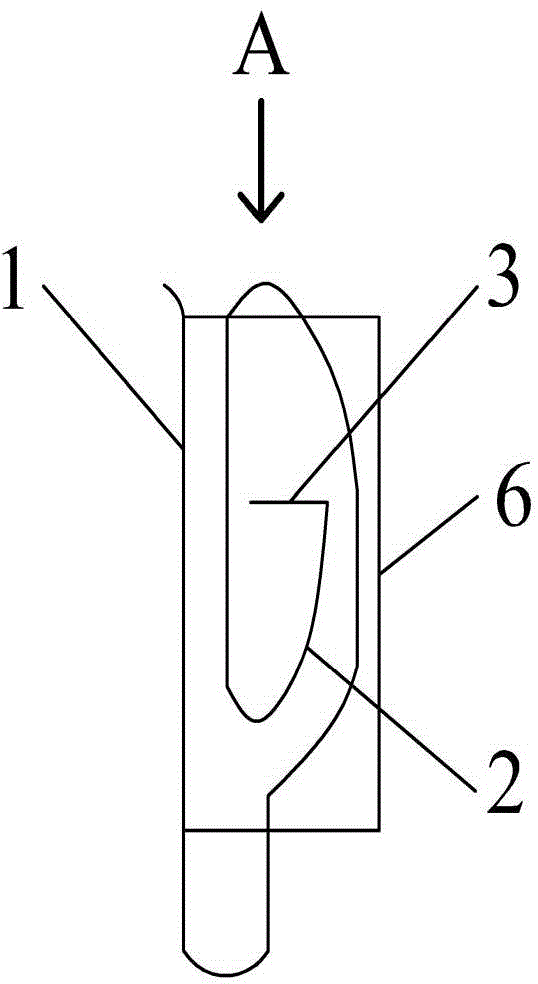

[0026] Embodiment two: see image 3 and Figure 4 , a plug-in component, the fixed sleeve 6 includes two oppositely arranged plate-type contact pieces 1, the lower end of the contact piece 1 is an integrated structure, which can meet the torsional deformation in a small angle range, and the surface contact and plane pressure increase the contact. The stability of the chip; at the same time, the one-time welding with the wire is reduced, the reliability of the contact piece 1 is improved, and the reduction of the solder joints also reduces the contact resistance. After one of the contacts is bent outwards, it continues to extend upwards and bends inwards to form a return spring 2 . The end of the return spring 2 is provided with a limiting plate 3 perpendicular to the contact piece 1 . The tops of the two contacts form a V-shaped socket, which is convenient for the insertion of the object to be contacted. This structure can be applied to terminal connectors. Figure 4 yes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com