Modular extension socket with lock

A modular and lockable technology, which is applied in the direction of two-part connection devices, electrical components, coupling devices, etc., can solve the problems of easy deflection of modules, large deflection, single function, etc., and achieves easy manufacturing, reliable connection, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

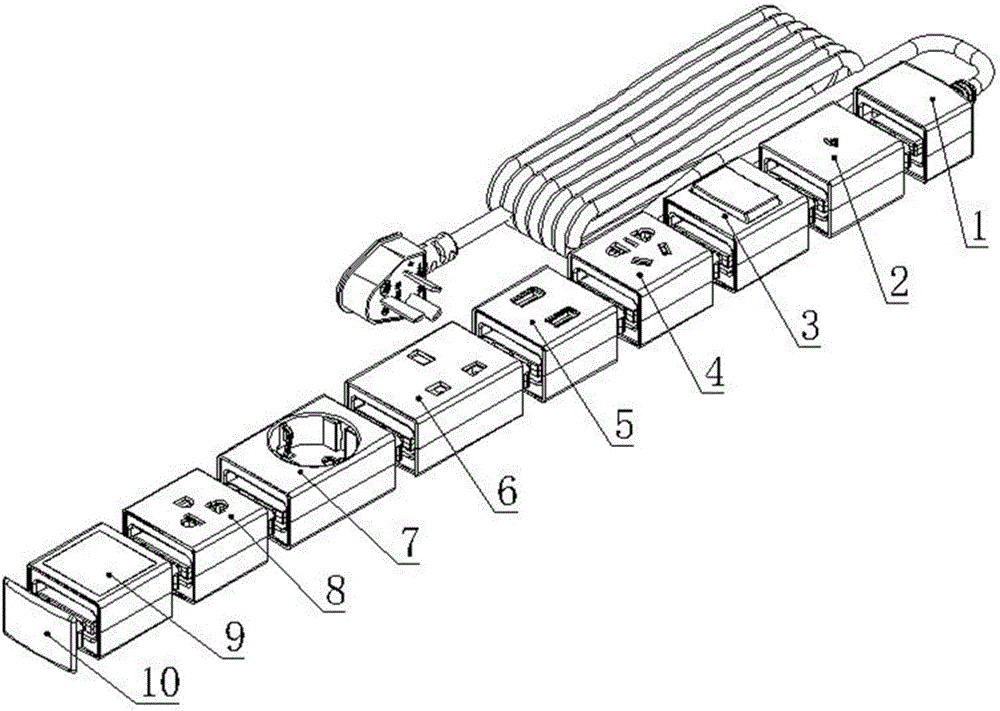

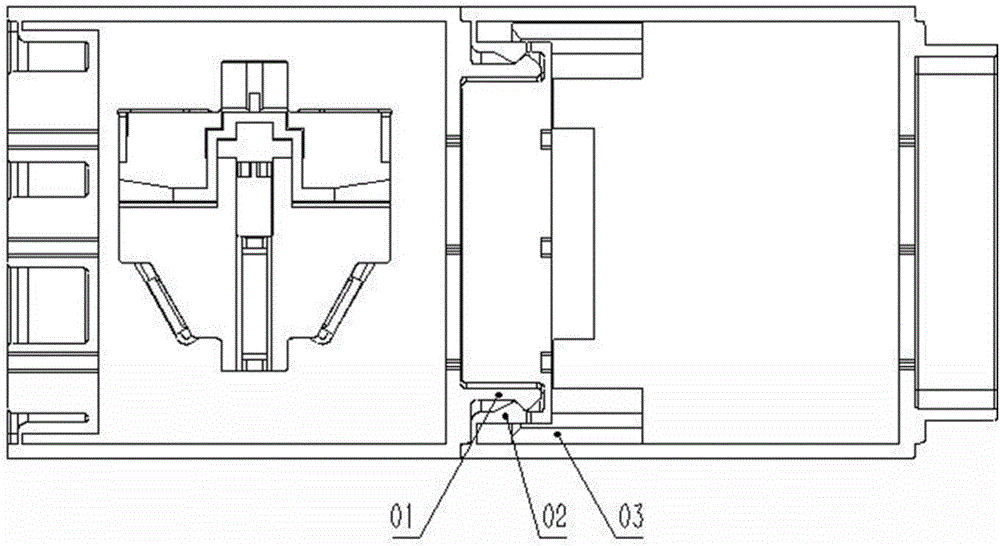

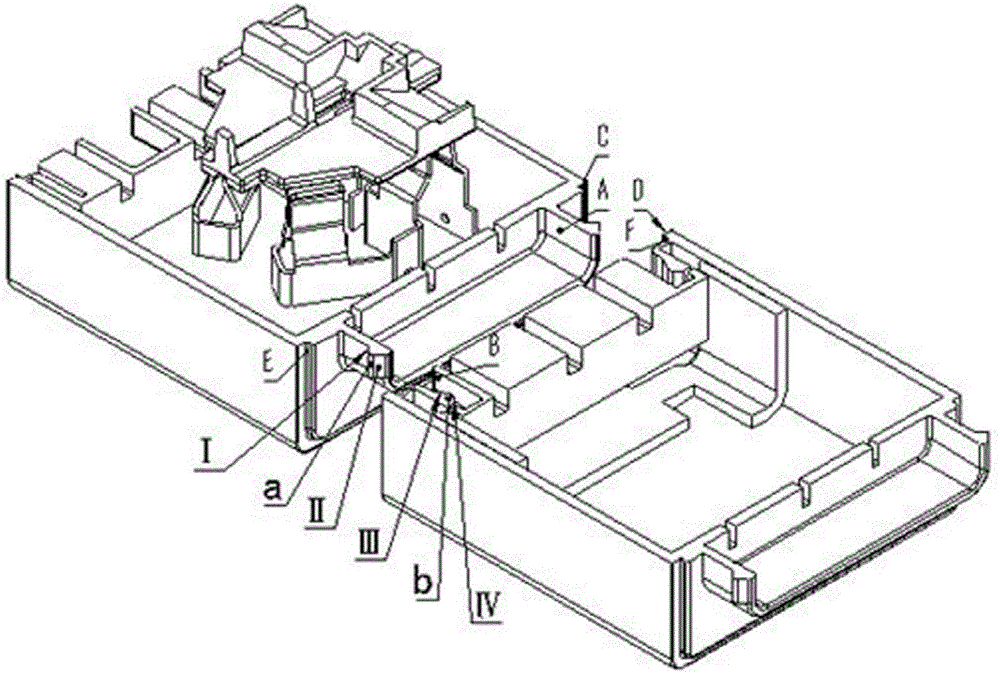

[0026] like Figure 1-3 As shown, a modular locking strip includes a power module 1 and a number of functional modules, the electrical output of the power module 1 is provided with a female plug connector, and the electrical input of the functional module is provided with a male plug connector, the electrical output end of the functional module is provided with a female plug connector with the same structure as the electrical output end of the power module, and a female plug buckle 02 is provided on both sides of the front end of the female plug connector, and a female plug buckle 02 There is a first double inclined wedge b composed of the third inclined plane III and the fourth inclined plane IV, and a male inserting collar 01 is provided on both sides of the front end of the male inserting joint, and the male inserting collar 01 is provided with a The second double bevel a composed of the first bevel I and the second bevel II, the first double bevel b and the second double b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com