Permanent magnet motor employing PCB winding

A permanent magnet motor and winding technology, which is applied in the shape/style/structure of winding conductors, electrical components, and electromechanical devices, etc., can solve the problems of difficult winding of motor windings, complicated processes, etc., to suppress eddy current loss, improve efficiency, The effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

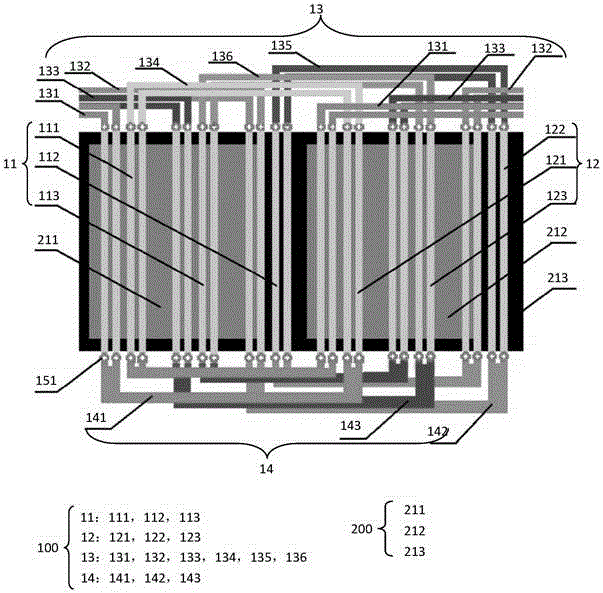

[0017] An example of the present invention is figure 1 As shown, only the partial structures of the PCB assembly 100 and the magnetic steel assembly 200 are shown. figure 1 middle:

[0018] 111 is the motor PCB winding U-phase winding conductor U1,

[0019] 112 is the motor PCB winding V-phase winding conductor V1,

[0020] 113 is the motor PCB winding W phase winding conductor W1,

[0021] 121 is the motor PCB winding U-phase winding conductor U2,

[0022] 122 is the motor PCB winding V-phase winding conductor V2,

[0023] 123 is the motor PCB winding W phase winding conductor W2,

[0024] 131 is the U-phase end A1 of the motor PCB winding,

[0025] 132 is the motor PCB winding V-phase end A1,

[0026] 133 is the motor PCB winding W-phase end A1,

[0027] 134 is the motor PCB winding U-phase end A2,

[0028] 135 is motor PCB winding V-phase end A2,

[0029] 136 is the motor PCB winding W-phase end A2,

[0030] 141 is the U-phase end B of the motor PCB winding,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com