Biaxially-oriented porous film

A porous membrane, biaxial stretching technology, applied in membrane technology, semi-permeable membrane separation, non-aqueous electrolyte and other directions, can solve the problems of easy membrane breakage, durability and reliability of biaxially oriented membrane, and easy breakage. , to achieve the effect of excellent homogeneity, high strength and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

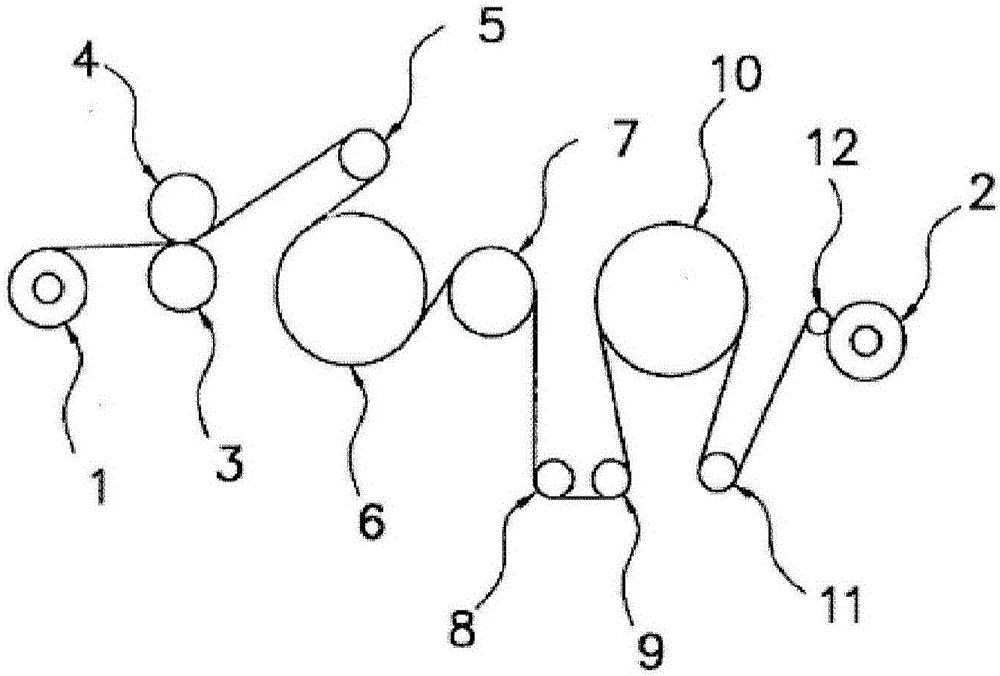

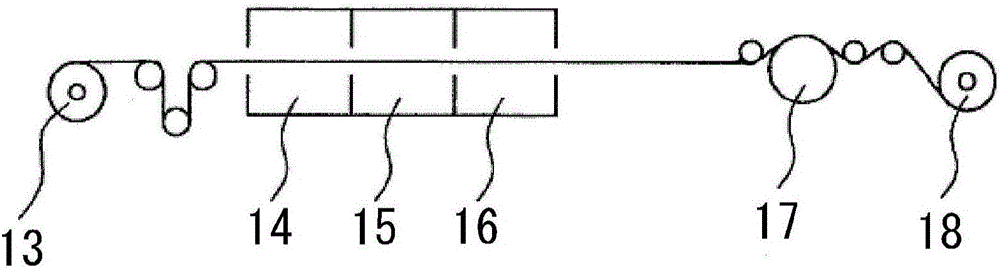

[0430] (extrusion and calendering)

[0431] With respect to 100 parts by weight of fine powder A (PTFE-A) of modified PTFE obtained in Production Example 1, 28 parts by weight of hydrocarbon oil ("IP solvent 2028" manufactured by Idemitsu Kosan Co., Ltd.) was added as an extrusion aid and mixed and allowed to stand for 12 hours.

[0432] Next, the mixture of the fine powder A (PTFE-A) and the extrusion aid was put into a 100φmm preforming machine, and compressed at a pressure of 3 MPa to obtain a preform. Next, the above-mentioned preform was placed in an extruder with an inner diameter of 100 mm previously provided with a die with an inner diameter of 16 mmφ, and paste extrusion was performed to obtain a PTFE molded body.

[0433] Furthermore, the obtained PTFE molded body was molded (calendered) into a film shape by calender rolls to obtain an unfired PTFE film.

[0434] The hydrocarbon oil was evaporated and removed by a hot air drying furnace to obtain a strip-shaped unf...

Embodiment 2~5 and comparative example 1~4

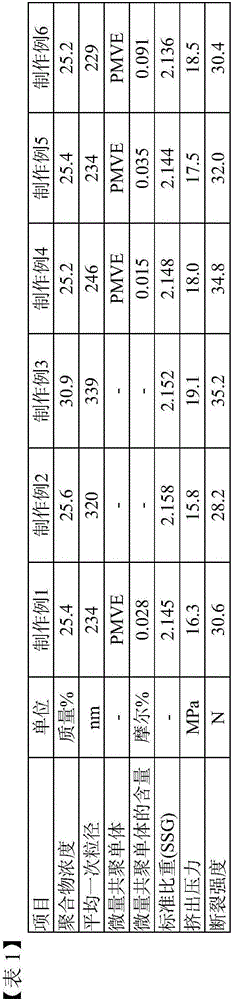

[0459] Except having changed the kind of PTFE raw material and the quantity of an extrusion aid (hydrocarbon oil) as described in Table 2, it processed similarly to Example 1, and obtained the porous film (biaxially-stretched film).

[0460] Various physical properties were measured in the same manner as in Example 1. The results are listed in Table 2.

[0461] In Examples 1 to 5, a homogeneous and high-strength biaxially stretched film was obtained. The biaxially stretched films obtained in Comparative Examples 1 and 2 were homogeneous but inferior in strength.

[0462] In Comparative Example 3, the round bar-shaped PTFE molded body obtained by paste extrusion was hard, and thus had poor calenderability, cracks occurred in the rolled product, and a homogeneous unfired PTFE film could not be obtained. In Comparative Example 4, even if the amount of extrusion aid was increased in order to lower the extrusion pressure, the obtained biaxially oriented film was poor in homogenei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com