Rotary tiller with tilting cutter

A technology for rotary tillers and knives, which is applied in the field of rotary tillers with inclined knives, can solve problems such as relying on manual rescue, no traction mechanism, and the inability of rotary tillers to provide lifting force for rotary tillers. Effects of labor intensity, increased tillage depth, and improved soil tillage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

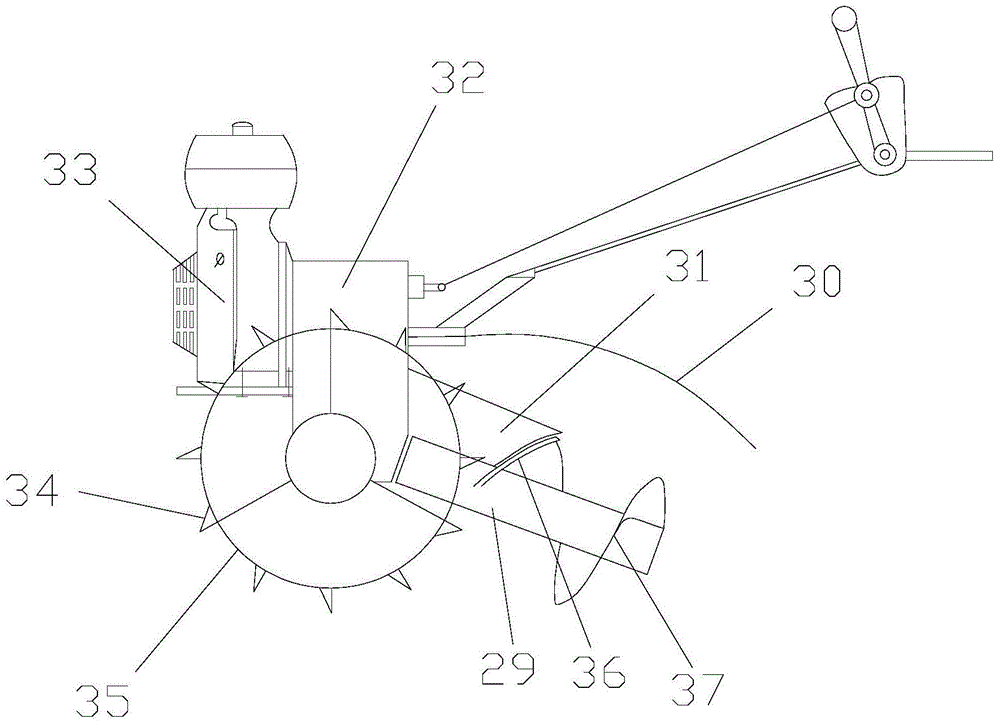

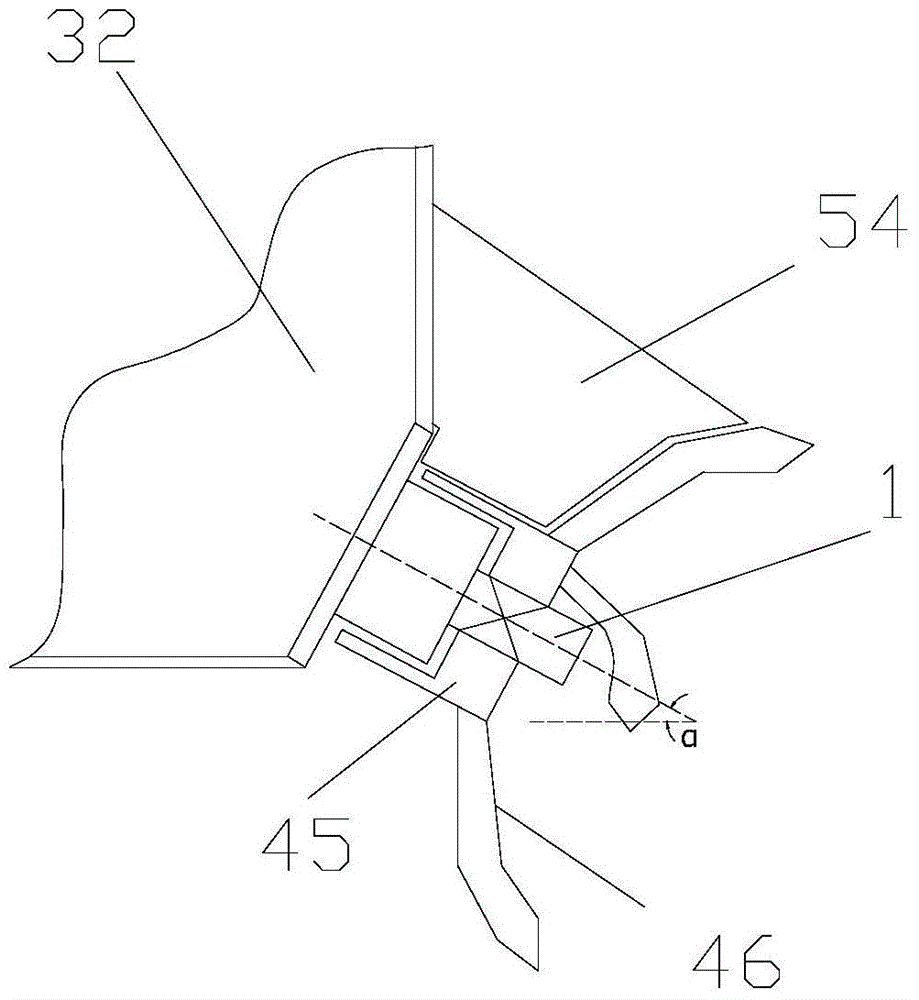

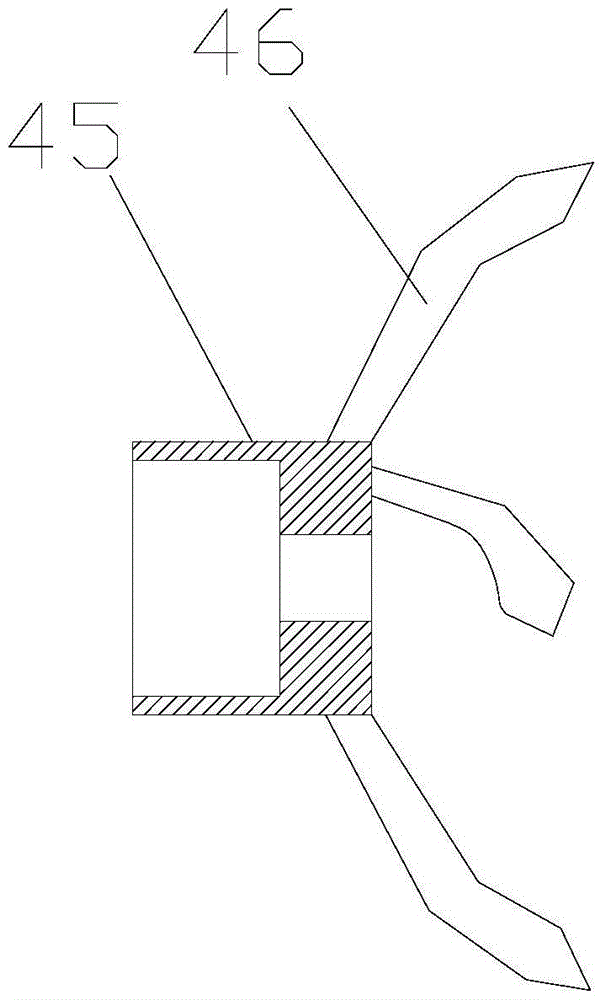

[0037] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the inclined cutter rotary cultivator of this embodiment includes a power unit 32, a traction wheel 35, a rotary tiller and is used to receive the power output by the power unit 32 and transmit the power respectively To the traction wheel 35 and the transmission box 32 of the rotary tiller; the axis of the rotary tiller is inclined downward so that the horizontal direction forms an included angle, and the range of the included angle α is: 20°<α<40°; in this embodiment The middle power unit 32 adopts a small-sized gasoline engine, and its output shaft is connected with the input shaft of the transmission box 32. The transmission box 32 stretches out the traction drive shaft 28 along the lateral direction of the rotary tiller to drive the traction wheel 35 to rotate, and the rearward direction along the longitudinal direction of the rotary tiller Stretch out cutter drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com