Nanometer composite filter material capable of killing bacteria and removing heavy metal in water

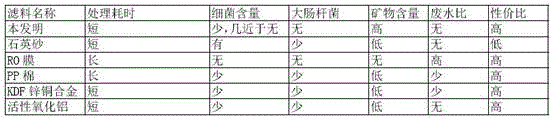

A nano-composite, filter material technology, applied in the direction of sterilization/microdynamic water/sewage treatment, biocide, filtration and separation, etc., can solve the problems that cannot be dealt with, the adsorption capacity of a single filter material, etc., and achieve no secondary pollution, excellent Bactericidal performance, the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

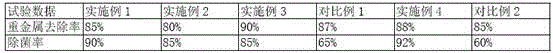

Examples

Embodiment 1

[0018] The nanocomposite material of the present invention includes seaweed mud, E33, zeolite powder, activated carbon and nano-titanium dioxide; first, weigh according to the formula: 20 parts of seaweed mud, 15 parts of shell powder, 10 parts of E33, 5 parts of zeolite powder, and activated carbon 20 parts and 5 parts of nano-titanium dioxide; then, mix seaweed mud, shell powder, E33 and zeolite powder, after grinding, stir and mix the resulting mixture with activated carbon, add water to prepare; finally carry out high-temperature firing at 1000 degrees Celsius After being released from the furnace, it is cooled to room temperature and mixed with nano-titanium dioxide to obtain a nano-composite filter material.

Embodiment 2

[0020] The nanocomposite material of the present invention includes seaweed mud, E33, zeolite powder, activated carbon and nano-titanium dioxide; first, weigh according to the formula: 50 parts of seaweed mud, 30 parts of shell powder, 25 parts of E33, 5 parts of zeolite powder, and activated carbon 35 parts and 15 parts of nano-titanium dioxide; then, mix seaweed mud, shell powder, E33 and zeolite powder, after grinding, stir and mix the resulting mixture with activated carbon, add water to prepare; finally carry out high-temperature firing at 1100 degrees Celsius After being released from the furnace, it is cooled to room temperature and mixed with nano-titanium dioxide to obtain a nano-composite filter material.

Embodiment 3

[0022] The nanocomposite material of the present invention includes seaweed mud, E33, zeolite powder, activated carbon and nano titanium dioxide; 40 parts and 20 parts of nano-titanium dioxide; then, mix seaweed mud, shell powder, E33 and zeolite powder, after grinding, stir and mix the resulting mixture with activated carbon, add water to prepare; finally carry out high-temperature firing at 1300 degrees Celsius After being released from the furnace, it is cooled to room temperature and mixed with nano-titanium dioxide to obtain a nano-composite filter material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com