Spiral-structure cutting steel wire and production device thereof

A technology for cutting steel wire and helical structure is applied in the field of cutting steel wire with a helical structure and its production equipment, and can solve the problems of increased processing procedures, wave height changes, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

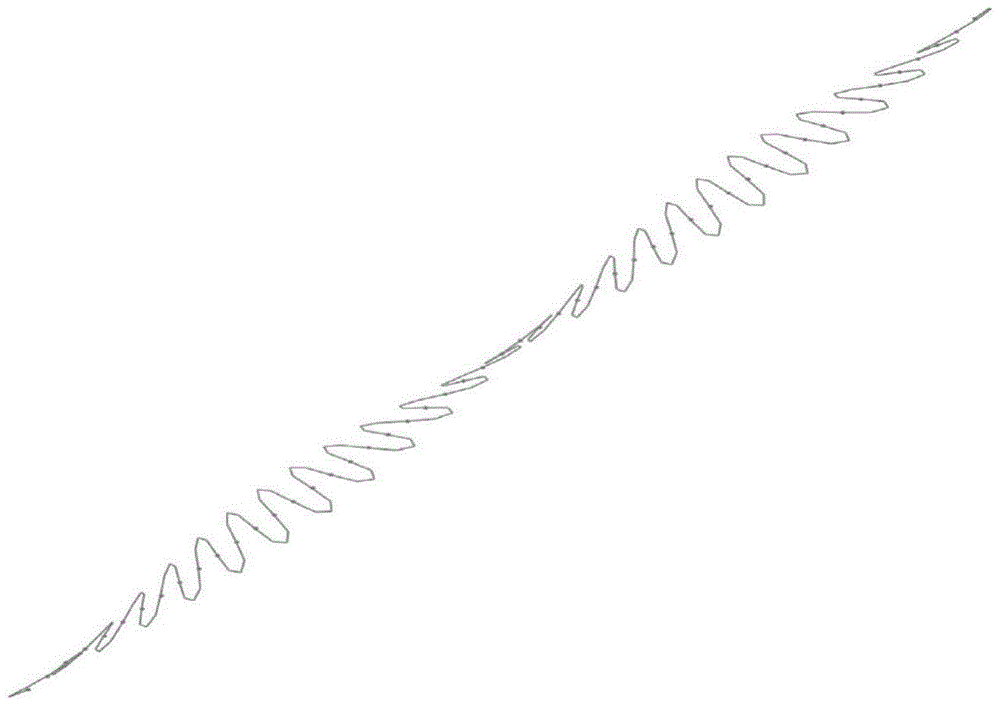

[0028] Such as image 3 As shown, a helical cutting steel wire production equipment of the present invention includes a rotatable cylindrical hollow casing 6, the casing 6 can be fixed by a bearing seat, and the casing 6 is driven to rotate by a motor. Here, for the convenience of description, the axial direction of the casing 6 is defined as the X-axis direction. The housing 6 is provided with a deformation device that applies bending deformation to the steel wire 1 passing through the rotating housing 6 , and the deformation device rotates synchronously with the housing 6 . In order to make the deformation on the steel wire 1 helically distributed along the axial direction of the steel wire body, the steel wire passing through the housing 6 cannot rotate, so two pairs of twist limiting wheels are arranged in the axial direction in the housing 6 . Wherein the first twist limiting wheel pair 2 includes a first winding wheel 201 and a second winding wheel 202 , and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com