Thermal foaming handheld inkjet printer provided with code reader inside

A technology of inkjet printer and code reader, which is applied in the direction of typewriter, printing, etc., to achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

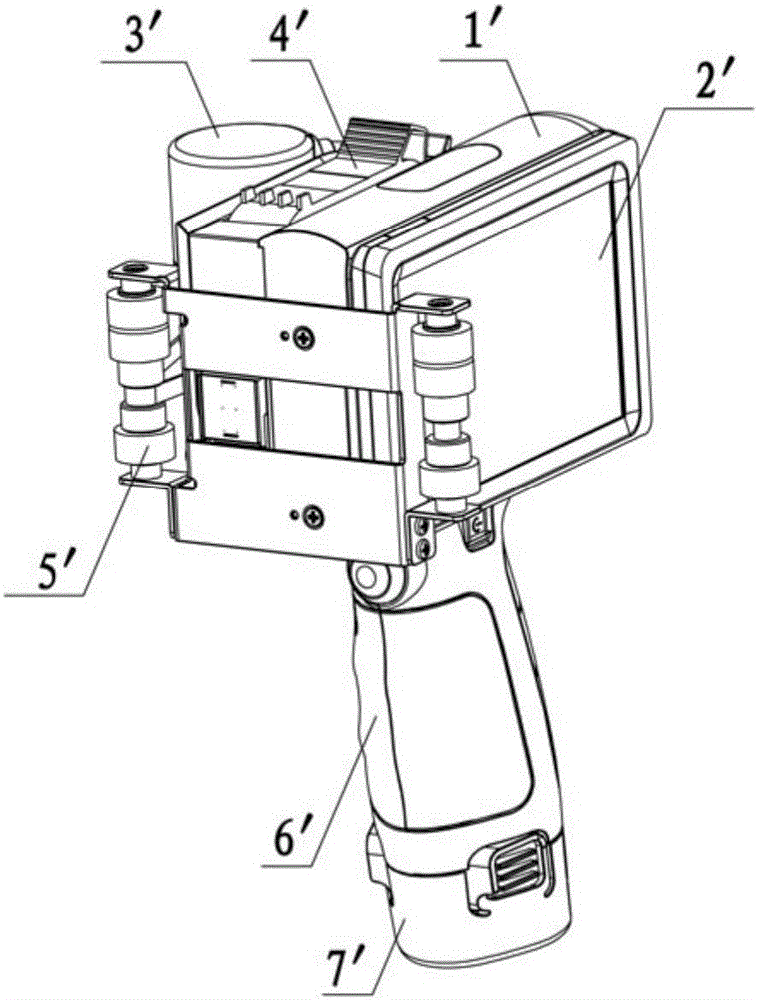

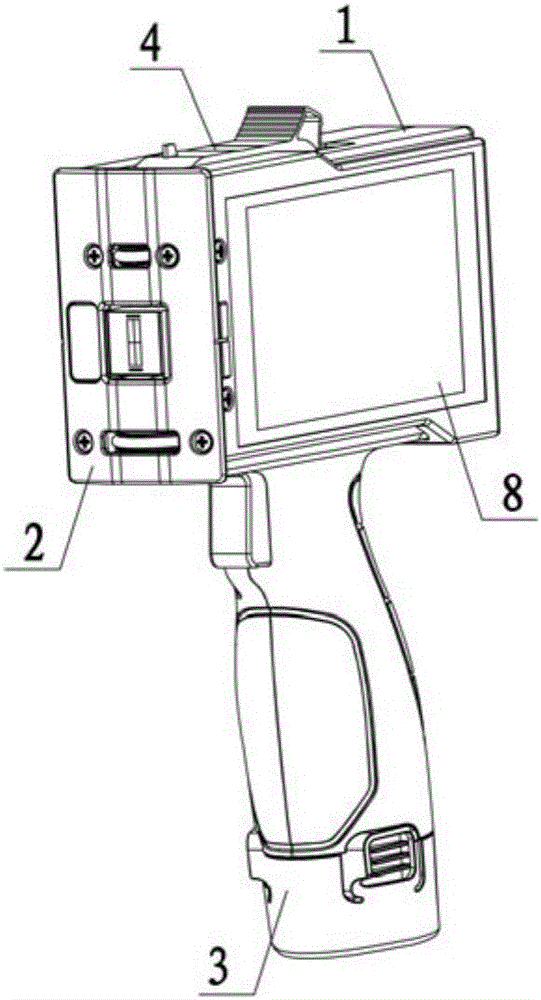

[0030] Such as figure 2 and image 3 As shown, a thermal foaming inkjet handheld inkjet printer with a built-in code reader includes a printer main body 1 with a handle, a roller module 2 arranged at the front end of the printer main body 1, and a roller module 2 installed at the bottom of the handle that can Unplugged battery3.

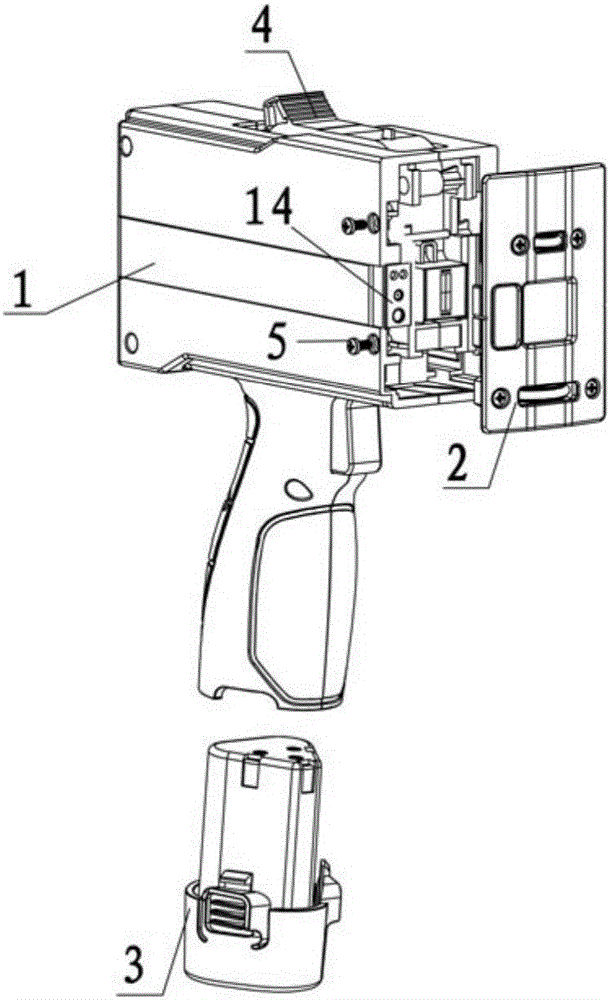

[0031] combine Figure 4 The exploded schematic diagram of the main body 1 of the inkjet printer is shown. The main body 1 of the inkjet printer includes a casing composed of an upper casing 6 and a lower casing 11, a nozzle module 7, a button module 9 and a battery arranged in the casing The adapter plate 10 and the capacitive screen 8 arranged on the side of the housing; the nozzle module 7 is respectively connected to the battery adapter plate 10 and the capacitive screen 8 through lines; To trigger, when the button of the button module 9 is pressed, the printing function is turned on; after the button is released, the printing function is tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com