Packaging material frame of automobile rear door glass assembly

A back door and glass technology, which is applied in the field of tooling for stacking consumables, can solve the problems of glass sliding damage, poor firmness, poor versatility, etc., and achieves good placement firmness, space saving, and good firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

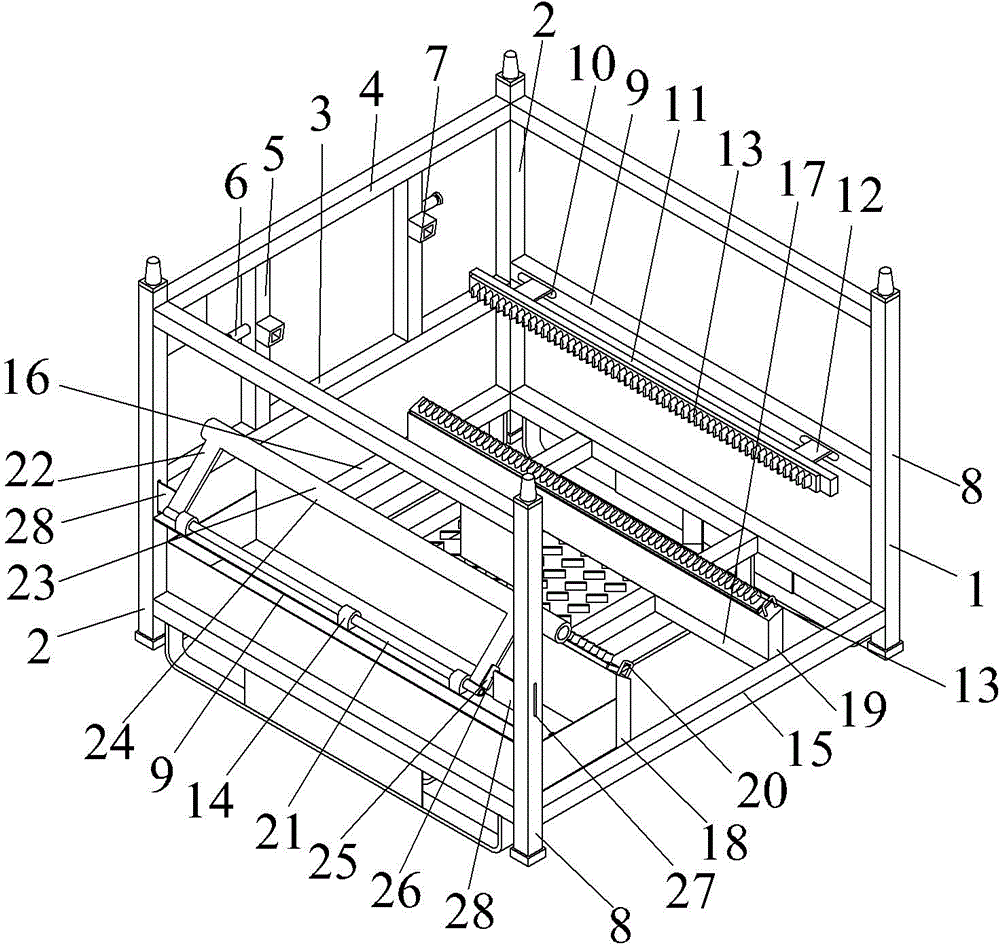

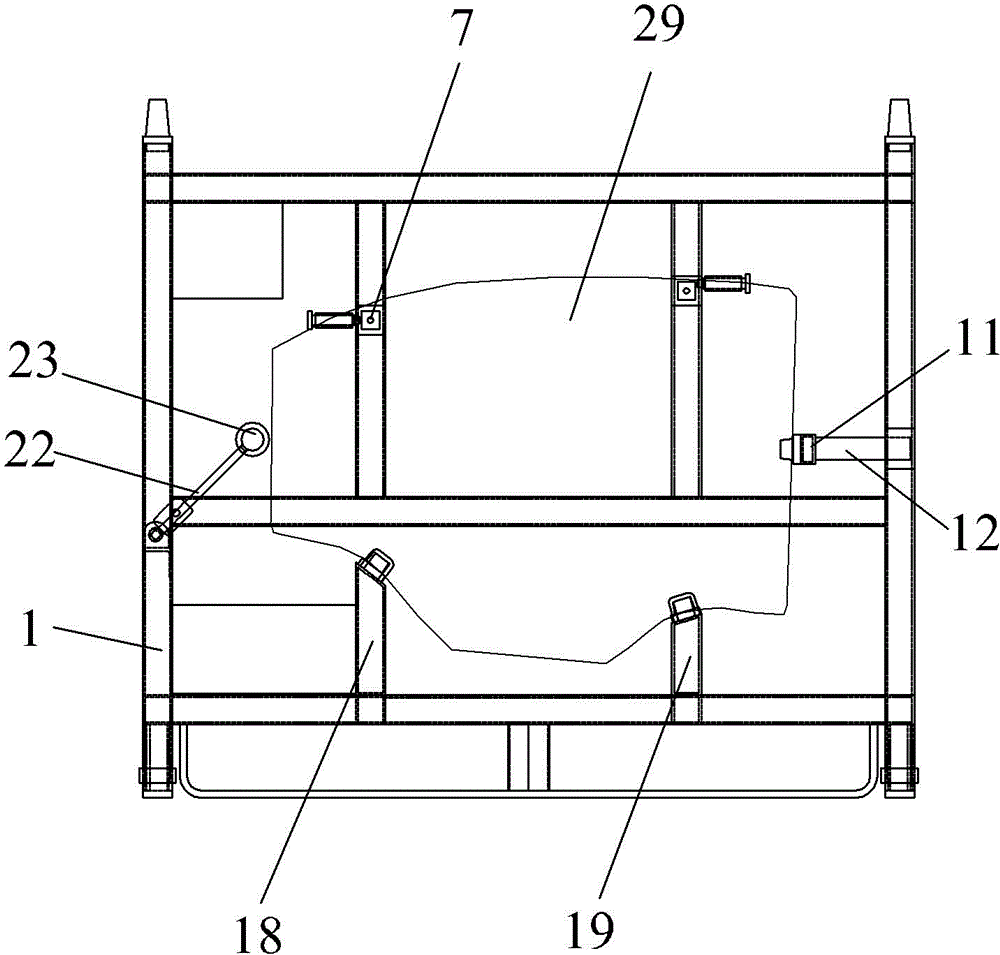

[0010] Such as figure 1 , figure 2 As shown, the present invention comprises a bracket 1 in a frame structure, a rear cross bar 3 is connected to the rear uprights 2 on both sides of the back of the bracket 1, and a rear cross bar 3 is fixed between the rear cross bar 3 and the rear push rod 4 of the support 1. Slide rail 5, fixed rubber spacer 7 by connecting bolt 6 in the slide rail 5, can effectively prevent the glass 29 that is placed on the support 1 from slipping, and the front column 8 and the rear column 2 at the two ends of the support 1 side are connected with Support plate 9, the two ends of the inner surface of the support plate 9 on one side are provided with draw-in slots 10, the retaining rod 11 is embedded in the draw-in groove 10 through the struts 12 protruding from its two ends, and the inner end surface of the retaining rod 11 is equipped with a rack 13, On the support plate 9 on the other side, a shaft seat 14 is fixed, and a pressing device is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com