Maneuvering type roller way conveying mechanism for conveying

A roller conveying mechanism and motorized technology, applied in the direction of conveyor objects, rollers, rollers, etc., can solve problems such as safety hazards, unsatisfactory, accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Combine below Figure 1-2 The present invention will be described in detail.

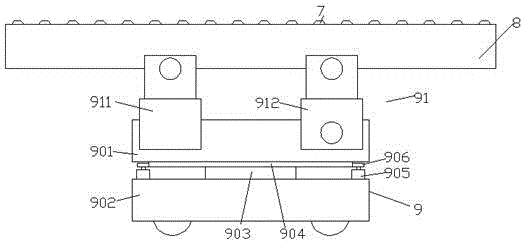

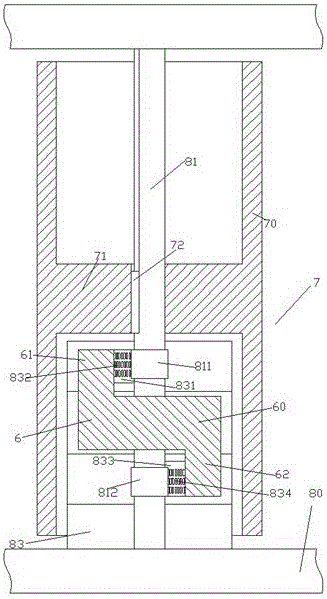

[0009] According to an embodiment of the present invention, the motorized roller conveying mechanism used for conveying includes a mobile cart 9 and a roller device 8 mounted on the motorized cart 9 through a height and inclination adjustment device 91 A series of rollers 7 are installed side by side in the roller table device 8, wherein the rollers 7 include a cylinder wall 70 and an integrally formed support disc 71 located in the axial middle of the cylinder wall 70, so that the support disc 71 The inner space of the cylinder wall 70 is divided into two chambers, the support plate 71 is mounted on the shaft 81 rotatably supported in the side wall 80 of the roller table device 8 through the key 72, wherein, At least one of the two chambers accommodates a fixed support frame 83 protruding from the side wall 80 of the adjacent roller table device 8, and the fixed support frame 83 carries a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com