Biaxial inertia excitation tamping pick

A technology of tamping picks and shaft inertia, applied in the directions of roads, tracks, ballast layers, etc., can solve problems such as low efficiency and poor vibration effect, and achieve the effects of convenient use, improved efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

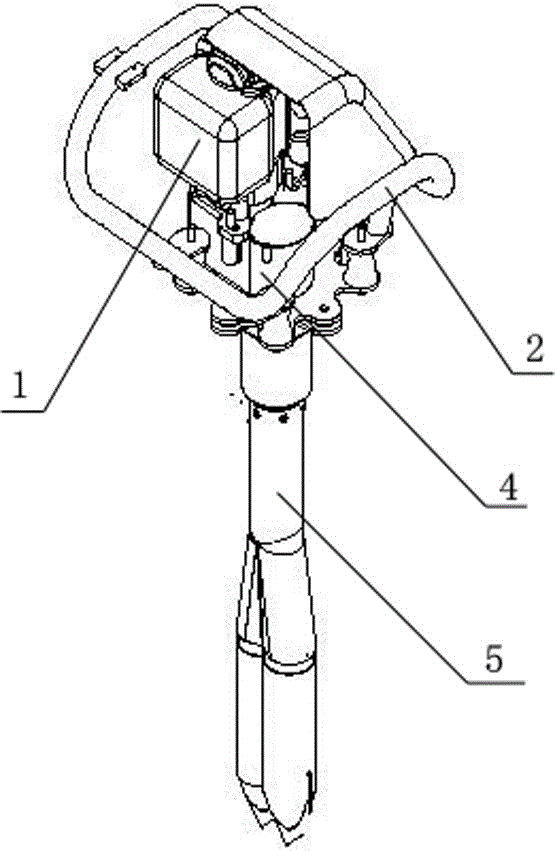

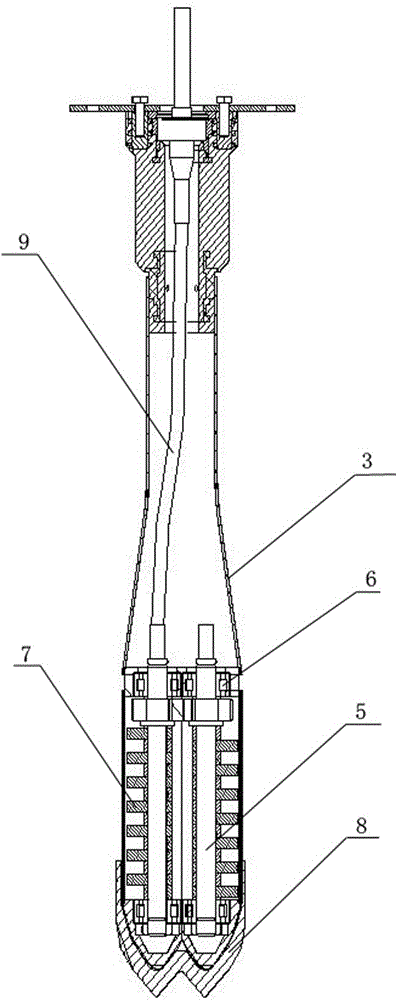

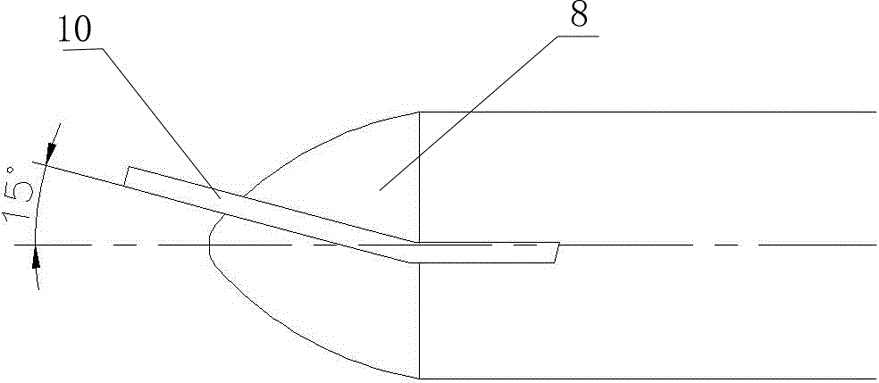

[0014] Embodiment 1: A kind of two-axis inertial excitation vibration tamping pick, with gasoline engine or diesel engine as the driving force 1, the tamping pick includes tamping handle 2, tamping shell 3, shock absorbing cylinder 4, transmission device and vibration excitation member, The shock absorbing cylinder 4 is fixed on the top of the tamping shell 3, the tamping handle 2 is installed on the shock absorbing cylinder 4, the vibration exciting member is arranged inside the tamping shell 3, and the exciting vibration component is connected with the driving force 1 through the transmission device; the exciting vibration component includes The excitation shaft 5, the eccentric gear set 6 and the eccentric assembly 7, the two excitation shafts 5 are arranged parallel to each other, the eccentric gear set 6 is two transmission gears meshing with each other, and the two transmission gears are respectively fixed on two excitation shafts. The top of the shaft 5 is driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com