A butterfly lock with lubricating structure

A lubricating structure, butterfly lock technology, applied in the field of butterfly locks, can solve the problems of not easy to twist, too tight, and achieve the effect of strengthening the lock structure and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

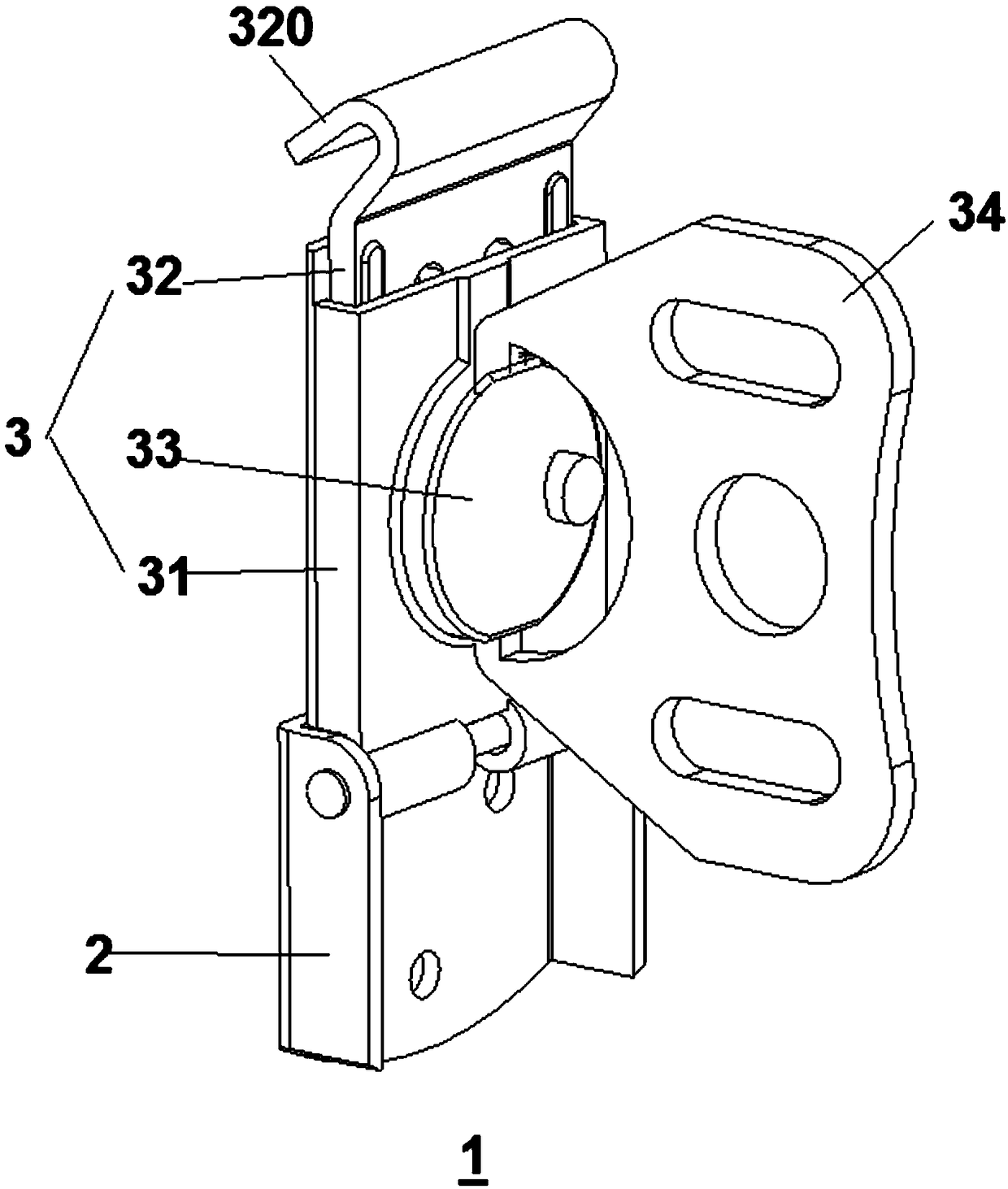

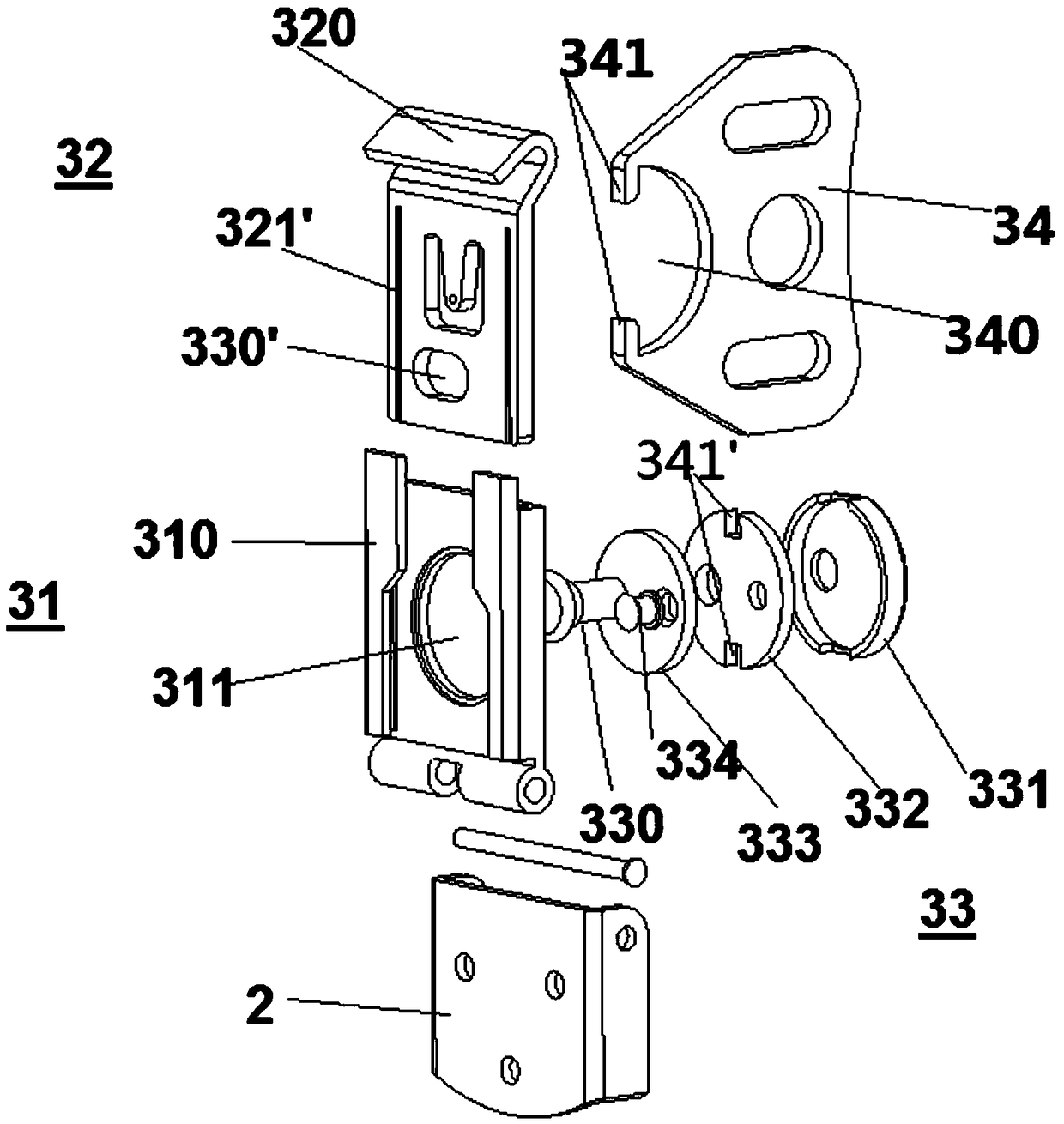

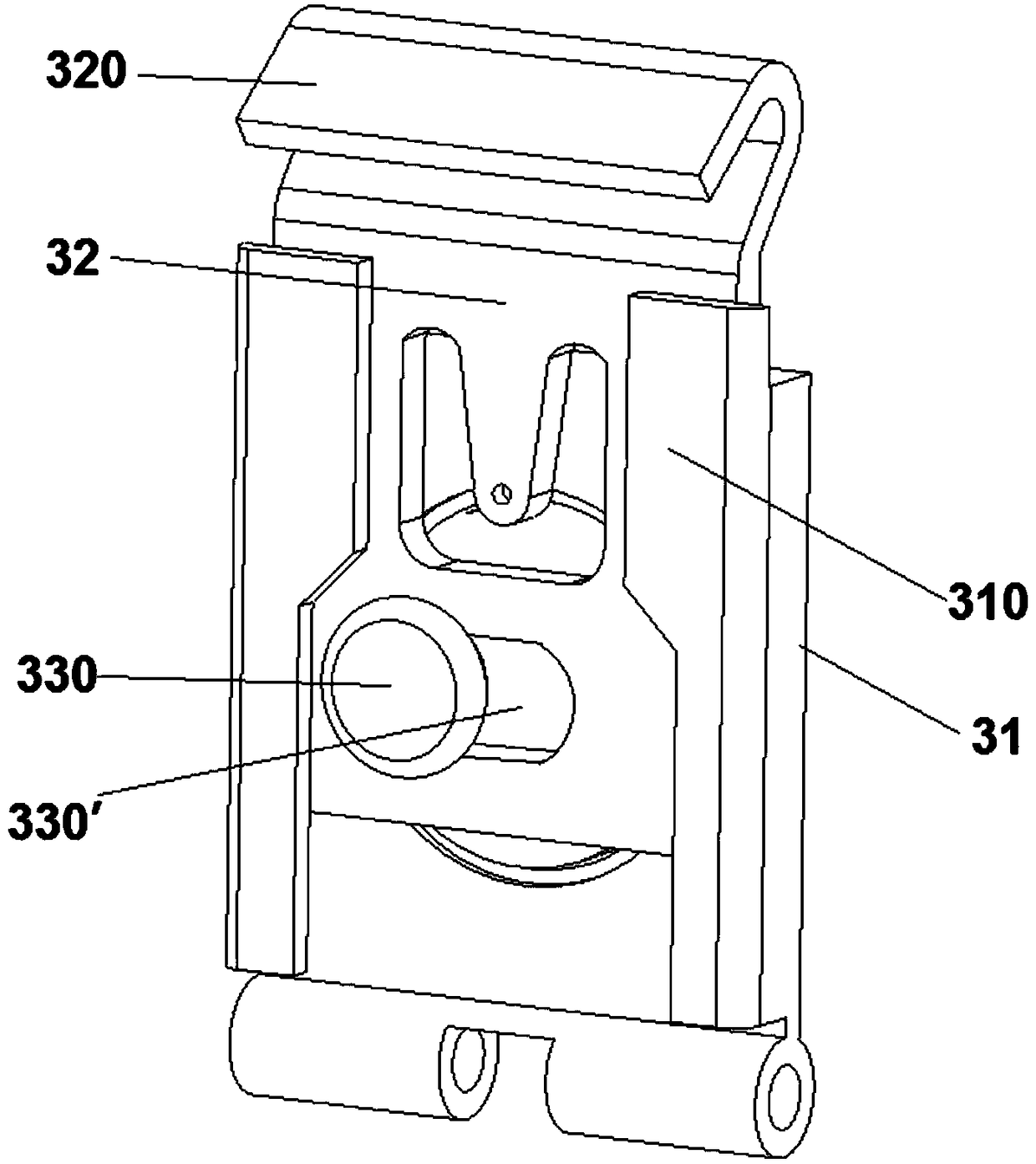

[0020] like Figure 1 to Figure 5 , an embodiment of a butterfly lock with a lubricating structure, including a main lock 1 and a secondary lock (not shown in the figure) fixedly installed on the upper and lower sides of the box respectively, and the lower side of the secondary lock is provided with a secondary hook The main lock 1 includes a base 2, a rotatable lock core 3 is hinged on the upper side of the base 2, and the lock core 3 includes a lock sleeve 31 hinged to the base 2 and a lock catch that slides up and down in the lock sleeve 31 32. The left and right sides of the lock sleeve 31 are curled to form side ribs 310 that limit the lock 32, and the upper side of the lock 32 is provided with a main hook that cooperates with the auxiliary hook 320, the lock 32 is driven by the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com