Coupling locking device

A technology for locking devices and couplings, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve problems such as disassembly and installation troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

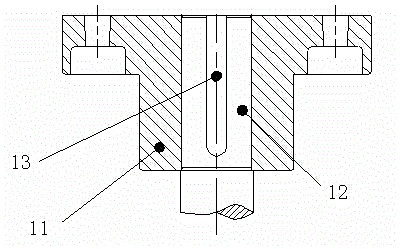

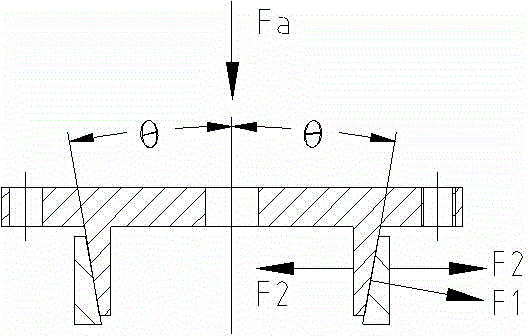

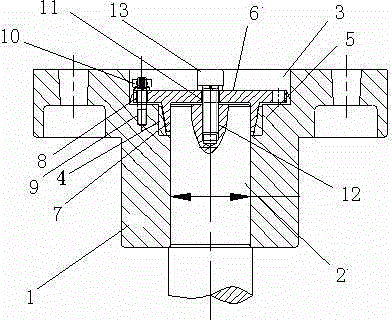

[0006] The coupling 1 and the shaft 2 in the figure are characterized in that: a large counterbore 3 is opened on the upper part of the shaft hole of the coupling, and then a small counterbore 4 is opened on the bottom of the large counterbore, and placed in the small counterbore A small taper sleeve 5, the outer sides of the cross-section of the small taper sleeve are right-angled sides, the slope is on the inside, the bottom is located at the bottom of the small counterbore, the right-angled side is located at the side of the small counterbore, and a large cone is placed in the large counterbore Sleeve 6, the bottom of the large taper sleeve has a convex taper sleeve 7, the inner sides of the cross section of the taper sleeve are right-angled sides, the outer side is a slope, the slope of the taper sleeve convex downward and the small cone The slopes of the cover are attached, and a threaded hole 8 is provided on the outside of the bottom of the large taper sleeve, and a corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com