Sealed type rotation compensator with V-shaped end faces

A technology of rotary compensator and end face sealing, which is applied in expansion compensation devices for pipelines, pipes/pipe joints/fittings, adjustable connections, etc., which can solve problems such as poor sealing performance and poor coaxiality, and achieve sealing Stable and long-lasting performance, avoiding direct contact, and improving the effect of sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following, the present invention will be further explained based on the drawings and the embodiments.

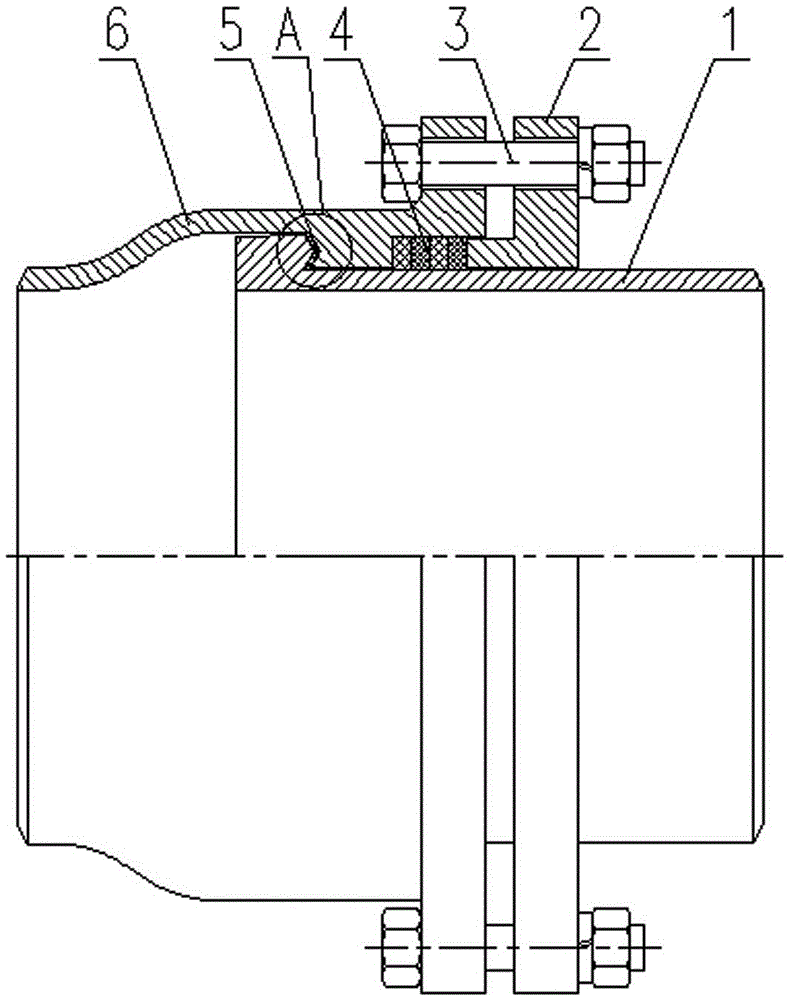

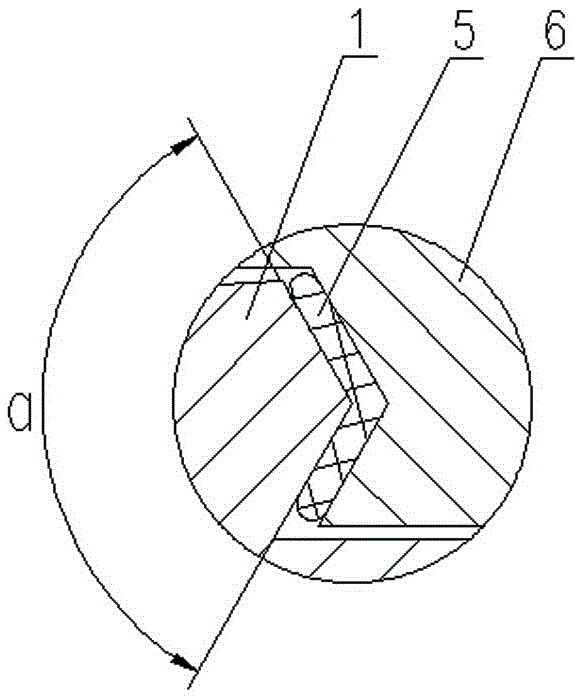

[0015] figure 1 The V-shaped end face sealed rotary compensator shown includes an inner tube 1, a gland 2, a bolt 3, a packing 4, a friction pad 5 and a sealing seat 6. The sealing seat 6 is a reducing tube, which is the main component of the rotation compensator, and its structural strength and manufacturing accuracy directly affect the pressure resistance and rotation quality of the product. The sealing seat 6 in the present invention adopts an integral structure. Because there is no welding seam in the structure, there are no hidden dangers such as welding defects and welding seam heat-affected zone, which can significantly improve the compression resistance and improve the manufacturing accuracy, so it can meet the requirements of high temperature and high pressure. Operating conditions. The inner tube 1 and the packing 4 coaxially fitted with the sealing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com