Petroleum pipeline blocking structure

A technology of oil pipelines and sealing caps, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of poor practicability, inconvenient use, and the blocking structure cannot realize the blocking function, etc., to prolong the service life , Reduce metal fatigue and ensure stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

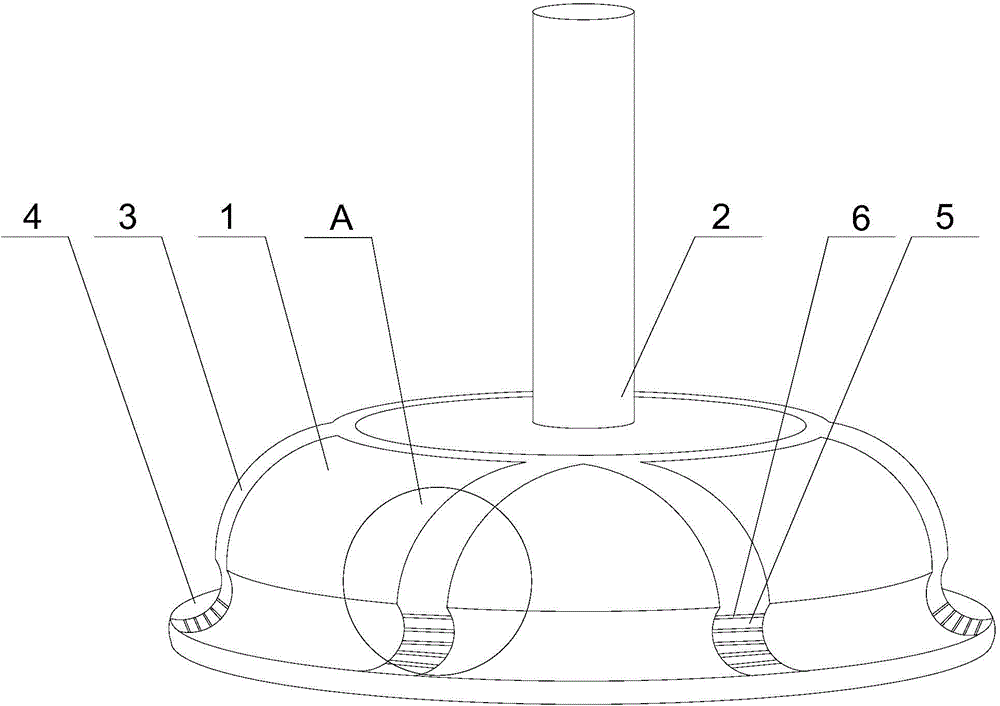

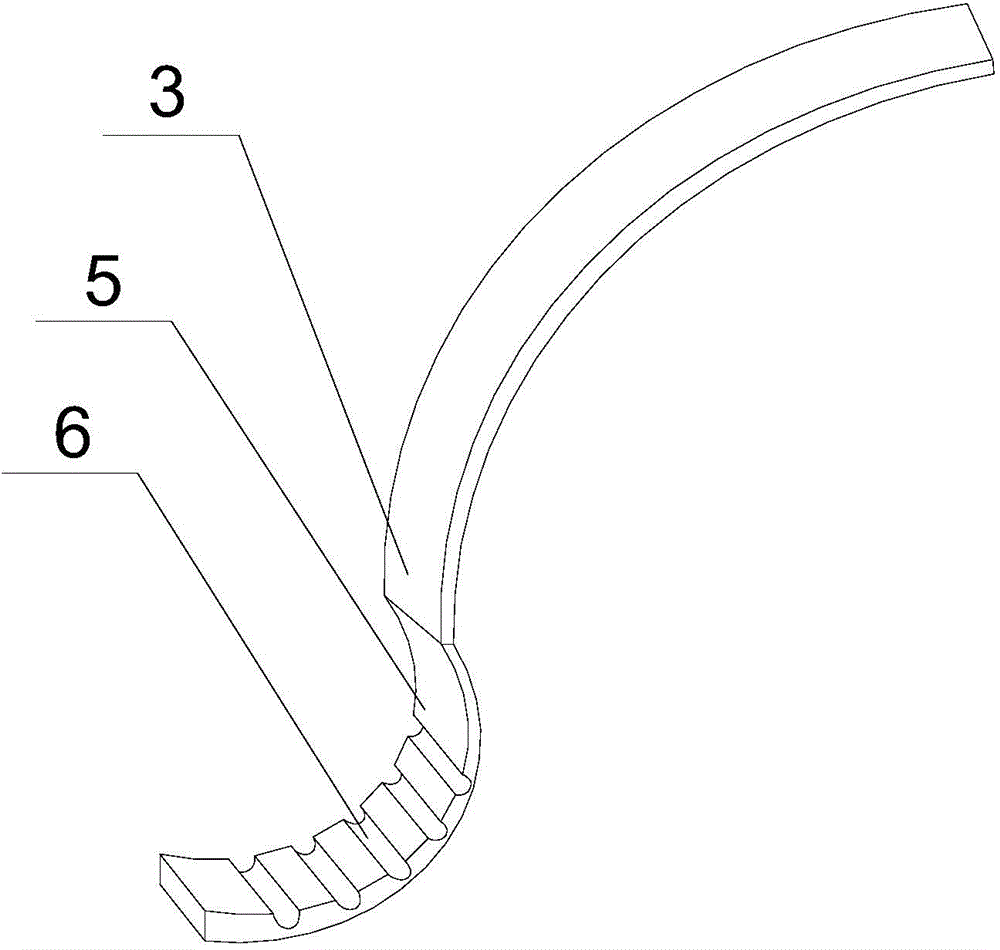

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes a hollow hemispherical sealing cover 1 and a push rod 2 fixed on the bottom of the sealing cover 1. On the outer eaves of the sealing cover 1, an annular enlarged part 4 with the middle part sunken inward is fixed. The enlarged part 4 is elastic rubber, and a plurality of arc-shaped pieces 3 are embedded on the outer wall of the sealing cover 1. The plurality of arc-shaped pieces 3 are radial along the direction from the bottom of the sealing cover 1 to its outer circumference. The end of the arc-shaped piece 3 is connected with an arc-shaped elastic metal block 5, and the elastic metal block 5 is embedded in the depression of the enlarged part 4; a plurality of contraction grooves are opened on the curved inner wall of the elastic metal block 5 6, and a plurality of said shrinkage grooves 6 are parallel to each other.

[0021] The present invention makes further improvements to the prior art. A push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com