Urban gas pipe robot adapting to pipe shape change

A technology of gas pipelines and robots, applied in the direction of pipes/pipe joints/fittings, special pipes, pipe components, etc., can solve the problems of being unable to adapt to three-way dense urban gas pipelines and complex control systems, and achieve online detection problems and traction Big, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, invention patent is described further.

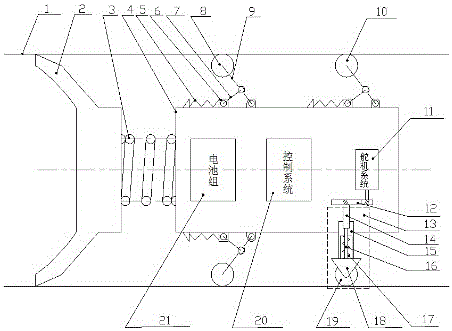

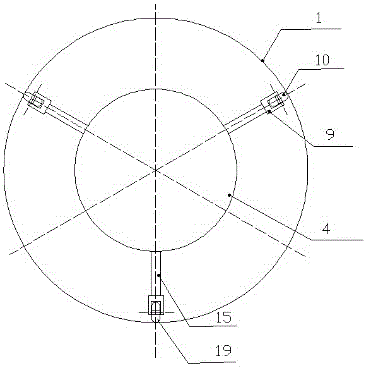

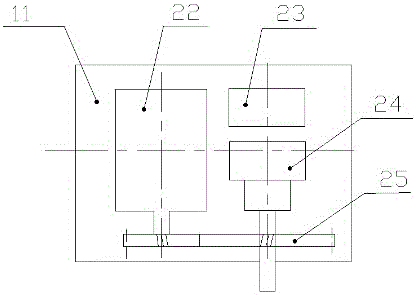

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of urban gas pipeline robot of the present invention adapts to pipeline shape change, mainly by power cup 2; Spring coupling 3; Frame 4; Tension spring 5; Slide block 6; Support connecting rod 7; 8; support arm 9; mileage wheel 10; steering gear system 11; gear set 12; telescopic system 13; telescopic rod 14; guide wheel frame 15; rotating shaft 16; telescopic spring 17; Control system 20; battery pack 21; motor 22; steering gear control board 23; potentiometer 24; The power cup 2 is connected to the spring coupling 3, and the spring coupling 3 is connected to the frame 4; the tension spring 5 and the slider 6 are connected to the frame 4 through bolts, and the support link 7 is connected to the support arm through a hinge 9 are connected; driven wheel 8, mileage wheel 10, guide wheel 19 are installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com