Graphite coating thickness measurement method

A technology of graphite coating and measuring method, which is applied in the field of heavy water reactor nuclear power fuel element manufacturing, can solve problems such as inaccurate measurement results and coating wear, and achieve the effects of not easy to wear, simple processing and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

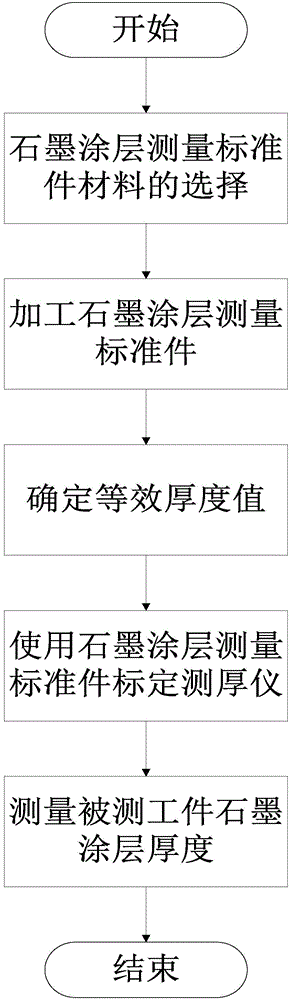

[0023] Such as figure 1 Shown, a kind of graphite coating thickness measuring method comprises the steps:

[0024] The first step: the selection of materials for graphite coating measurement standard parts;

[0025] Choose stainless steel to make graphite-coated measurement standard parts.

[0026] The second step: processing graphite coating measurement standard parts;

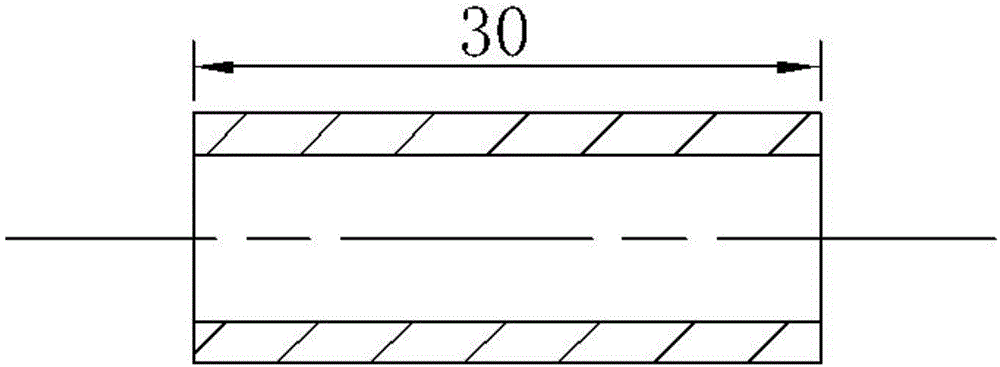

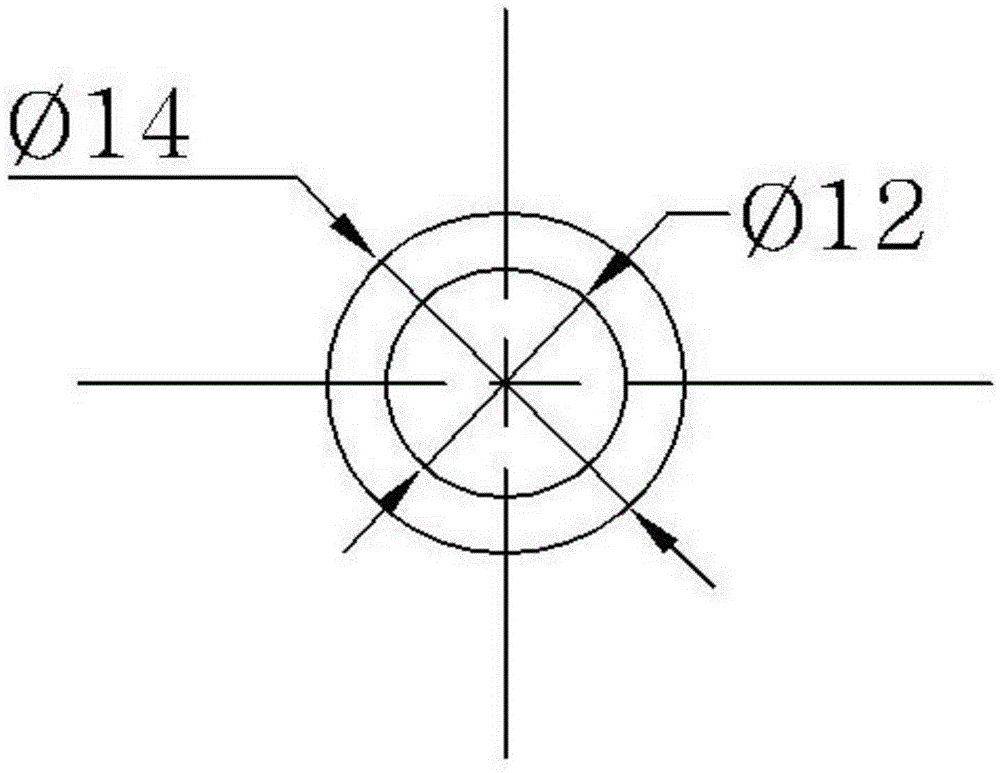

[0027] Such as figure 2 with image 3 As shown, a stainless steel tube with an inner diameter of 12mm, a wall thickness of 2mm and a length of 30mm is processed as a graphite coating measurement standard.

[0028] The third step: determine the equivalent thickness value;

[0029] A graphite coating of known thickness is used to calibrate the thickness gauge, the thickness gauge model MICRODERM700. Measure the equivalent thickness value of the graphite coating measurement standa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com