Device and method for calibrating high-precision temperature sensor

A temperature sensor, high-precision technology, used in thermometers, measuring devices, thermometer testing/calibration, etc., can solve the problems of high cost and slow calibration speed, and achieve the effect of fast calibration speed and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

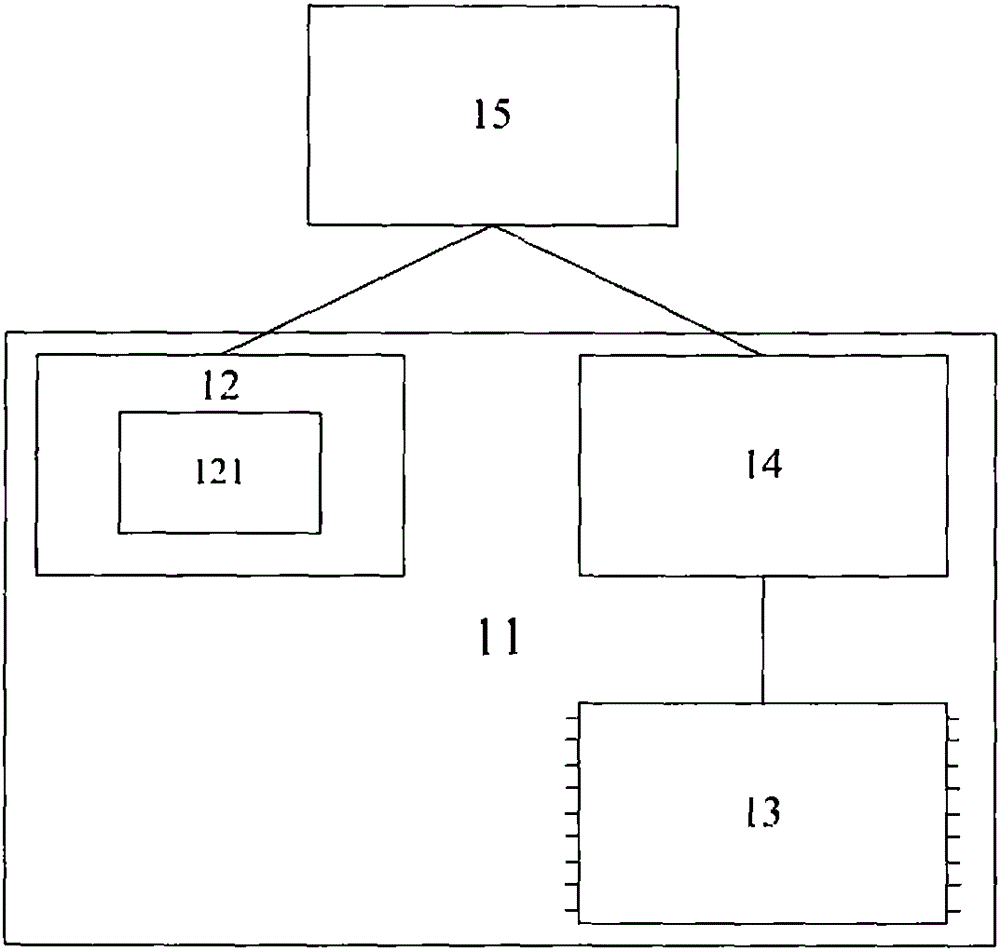

[0014] Embodiment 1, the device for calibrating a high-precision temperature sensor of this embodiment, see figure 1 As shown, it includes: a test board 11 , a high-precision temperature sensor 12 to be calibrated, a high-precision temperature reference element 13 and a high-precision analog-to-digital converter 14 placed on the test board 11 , and a reading unit 15 . The specific connection relationship is that the high-precision temperature reference element 13 , the high-precision analog-to-digital converter 14 and the reading unit 15 are connected in sequence, and the high-precision temperature sensor 12 to be calibrated is connected with the reading unit 15 . More preferably, the high-precision temperature reference element 13 can be integrated on the test board 11; the inside of the high-precision temperature sensor 12 to be calibrated also includes: a non-volatile storage medium 121, which is used to store the calibration data, and in the product When the terminal uses ...

Embodiment 2

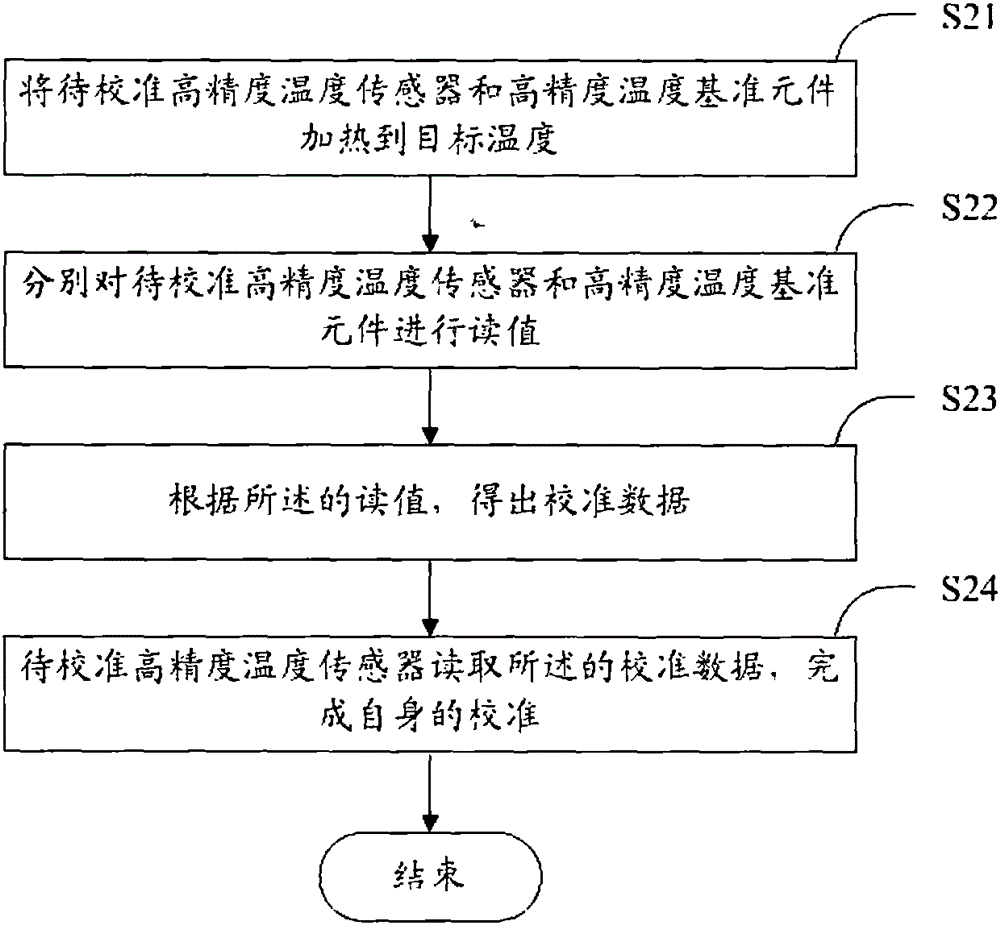

[0016] Embodiment 2, the method for calibrating a high-precision temperature sensor of this embodiment, see figure 2 shown, including the following steps:

[0017] S21. Heating the high-precision temperature sensor to be calibrated and the high-precision temperature reference element to the target temperature.

[0018] S22. Read the values of the high-precision temperature sensor to be calibrated and the high-precision temperature reference element respectively.

[0019] S23. Obtain calibration data according to the read value.

[0020] S24. The high-precision temperature sensor to be calibrated reads the calibration data to complete its own calibration.

[0021] In a specific implementation, the high-precision temperature sensor to be calibrated can use a Bluetooth temperature chip. In the chip final test (FT) stage, when designing the test board (loadboard), the Bluetooth temperature chip, the high-precision temperature reference element (that is, the calibrated high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com