A stepless adjustable push-rock composite wave maker

An adjustable and wave-making machine technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of single switching position and inconvenient switching, and achieve convenient adjustment and meet the needs of complexity and diversity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

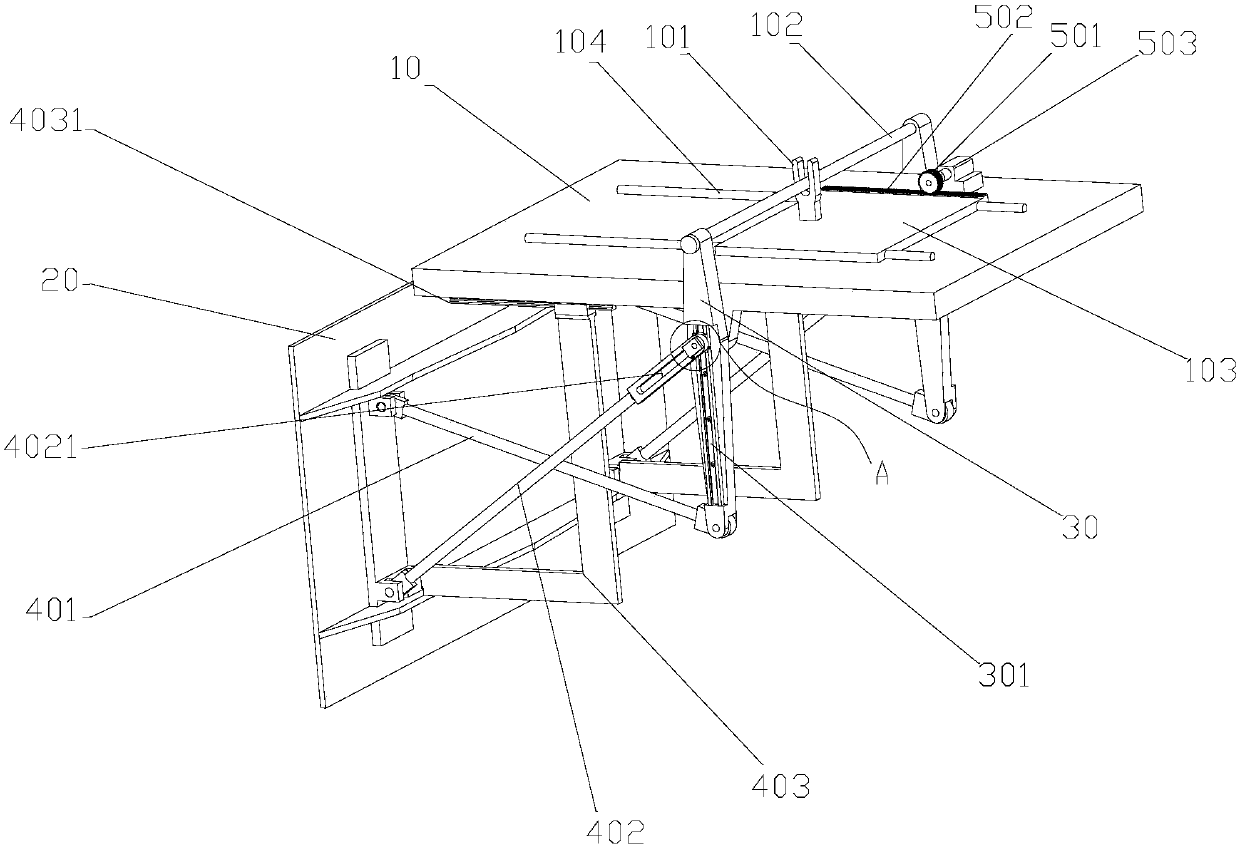

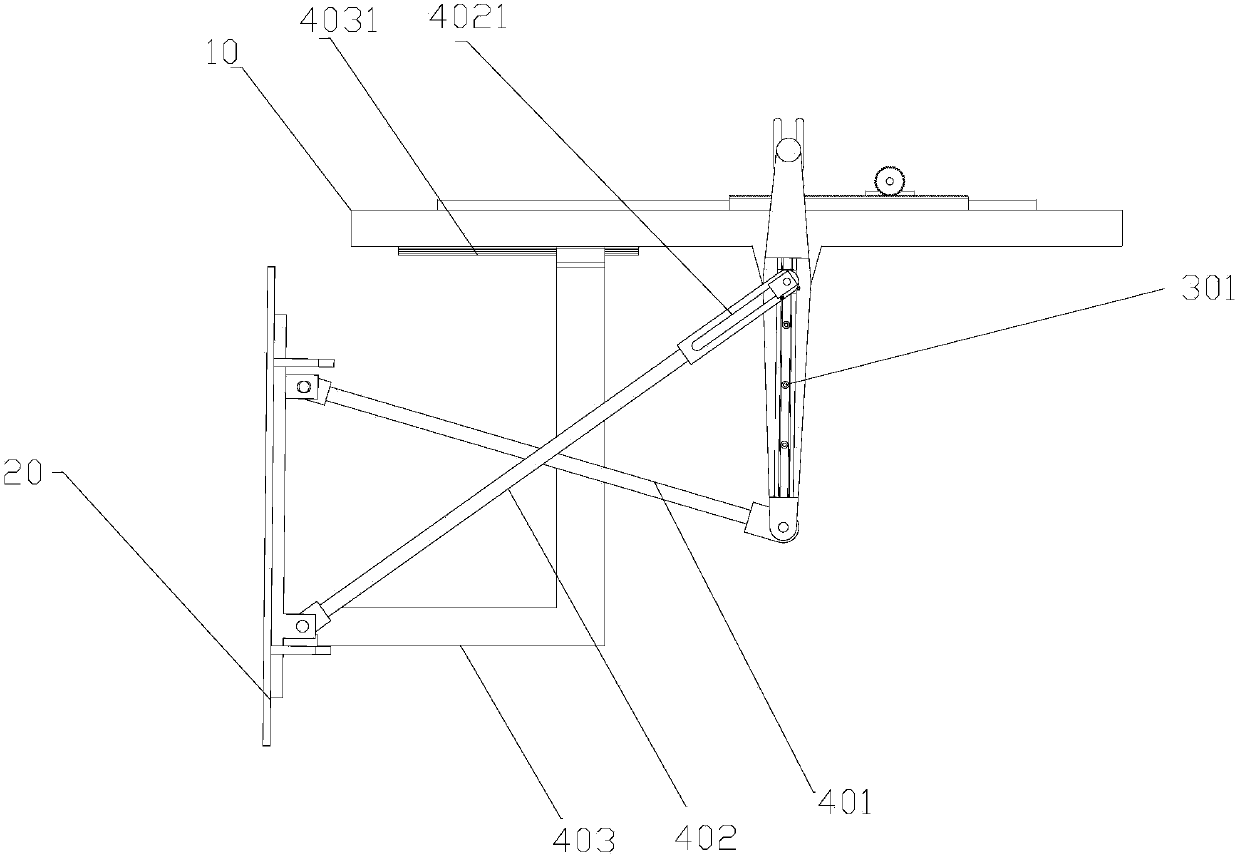

[0032] Such as Figure 1-2 As shown, it is a schematic structural diagram of a steplessly adjustable push-rock composite wave maker and a structural schematic diagram of a push rod mechanism according to an embodiment of the present invention, including a machine base 10, a shift fork 101, a cross bar 102, and a 10. The push wave plate 20 at the front end, the driving device for driving the movement of the push wave plate 20, the force rods 30 symmetrically arranged on both sides of the machine base 10 and hinged with the machine base, symmetrically arranged on both sides of the machine base and on the side of the driving device The push rod mechanism that pushes the push wave plate to move under the action and the slide table 103 connected with the driving device, wherein the slide table 103 is slidably connected to the machine base 10, one end of the shift fork 101 is fixedly arranged on the slide table 103, and the other end is connected to the horizontal The rod 102 and th...

Embodiment 2

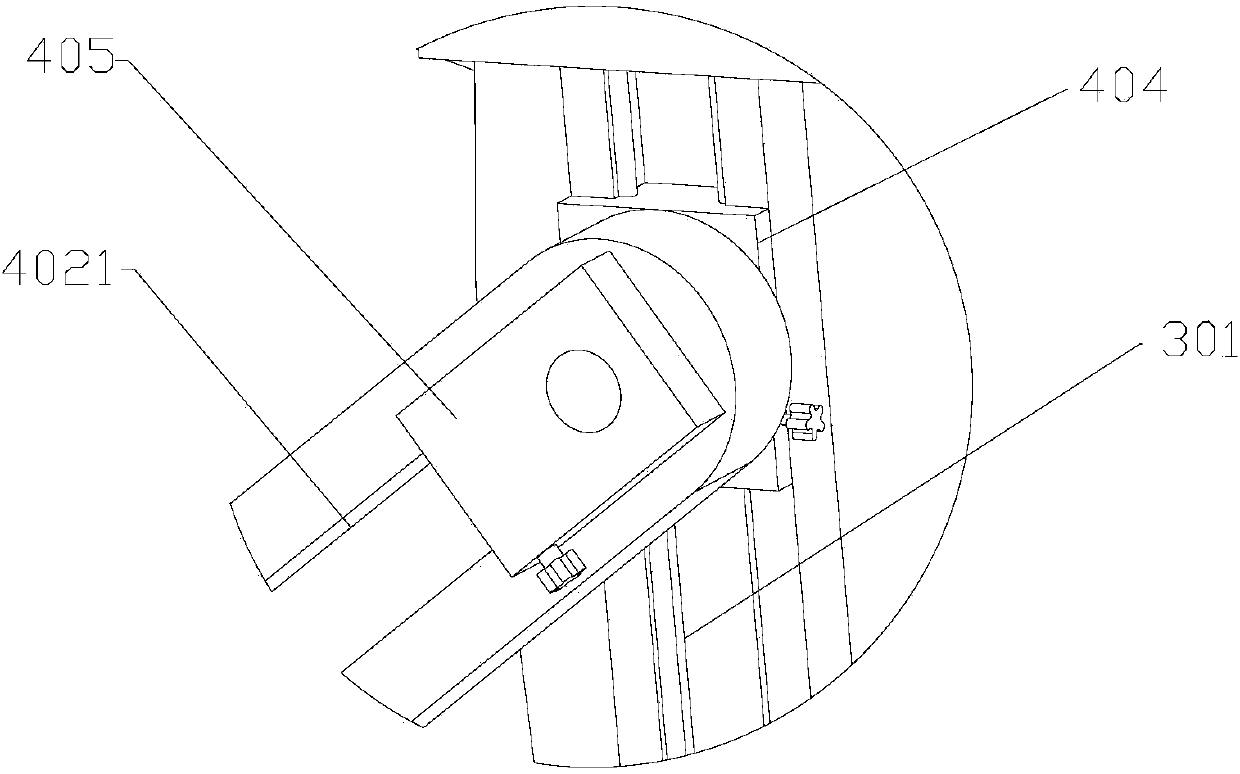

[0042] Such as image 3 As shown, it is a structural schematic diagram of the lock-lock slider of the steplessly adjustable push-rock compound wave maker in another embodiment of the present invention. On the basis of the first embodiment, the auxiliary push rod 402 is connected to the first slide rail 301 An adjustment slot 4021 for adjusting the length of the auxiliary push rod 402 is provided at one end of the shaft. The other end of the auxiliary push rod 402 is fixed on the first slide rail 301 through the lock slider. The lock slider includes a first lock slider 404 and a second lock slider 405. The first lock slider 404 can It is arranged on the first slide rail 301 in a manner of free movement on the first slide rail 301, and the second locking slider 405 is arranged in the adjustment groove 4021 at the other end of the auxiliary push rod 402. The first locking slider 404 and the second locking slider 404 The two locking sliders 405 are fixed by screws.

[0043] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com