Multi-angle stirring type water and fertilizer mixer

A water-fertilizer mixing and stirring technology, which is applied in the direction of mixers, shaking/oscillating/vibrating mixers, dissolving, etc., can solve the problems that fertilizers cannot be mixed together, affect the quality of water and fertilizer mixtures, and the mixing is not uniform enough to avoid falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

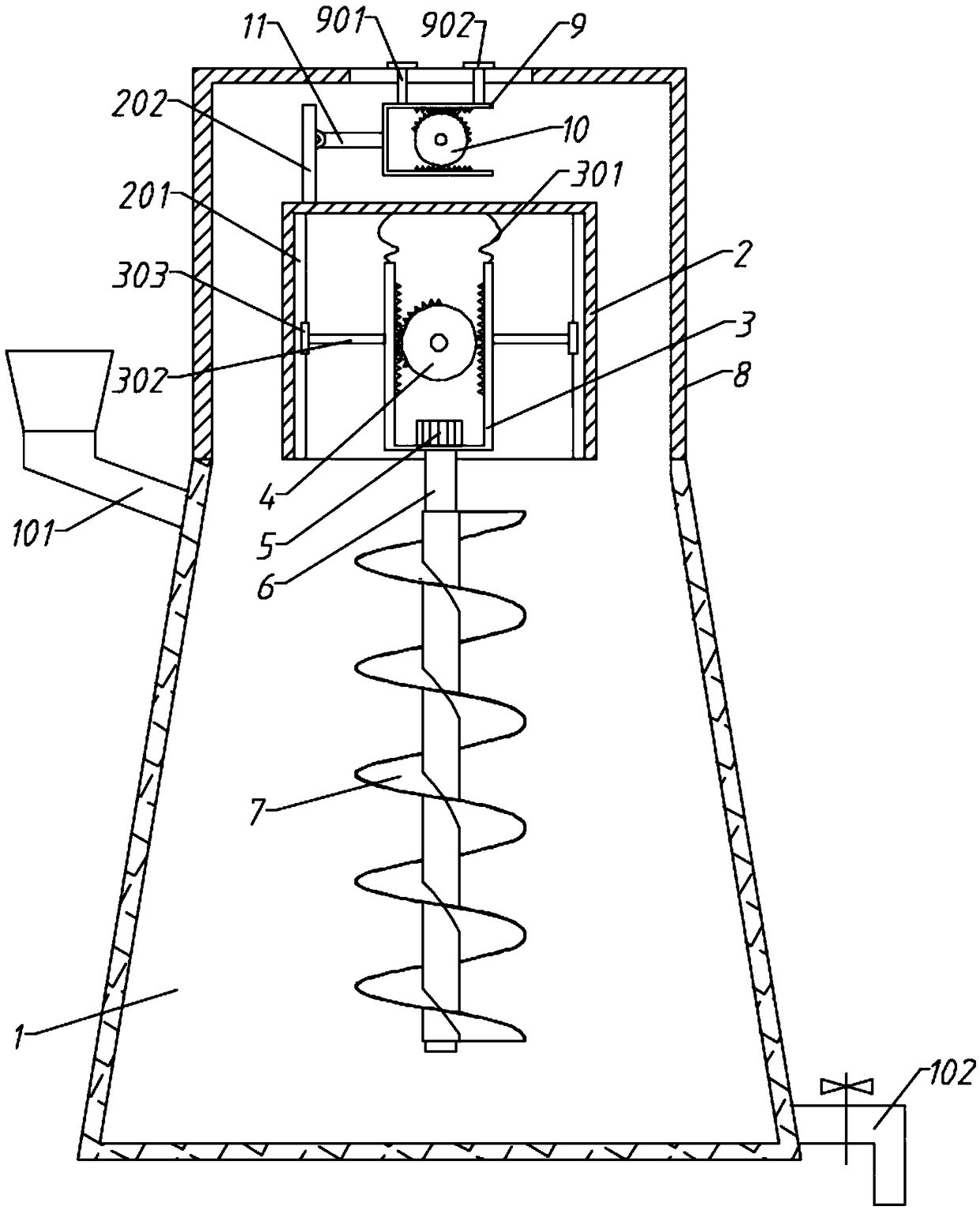

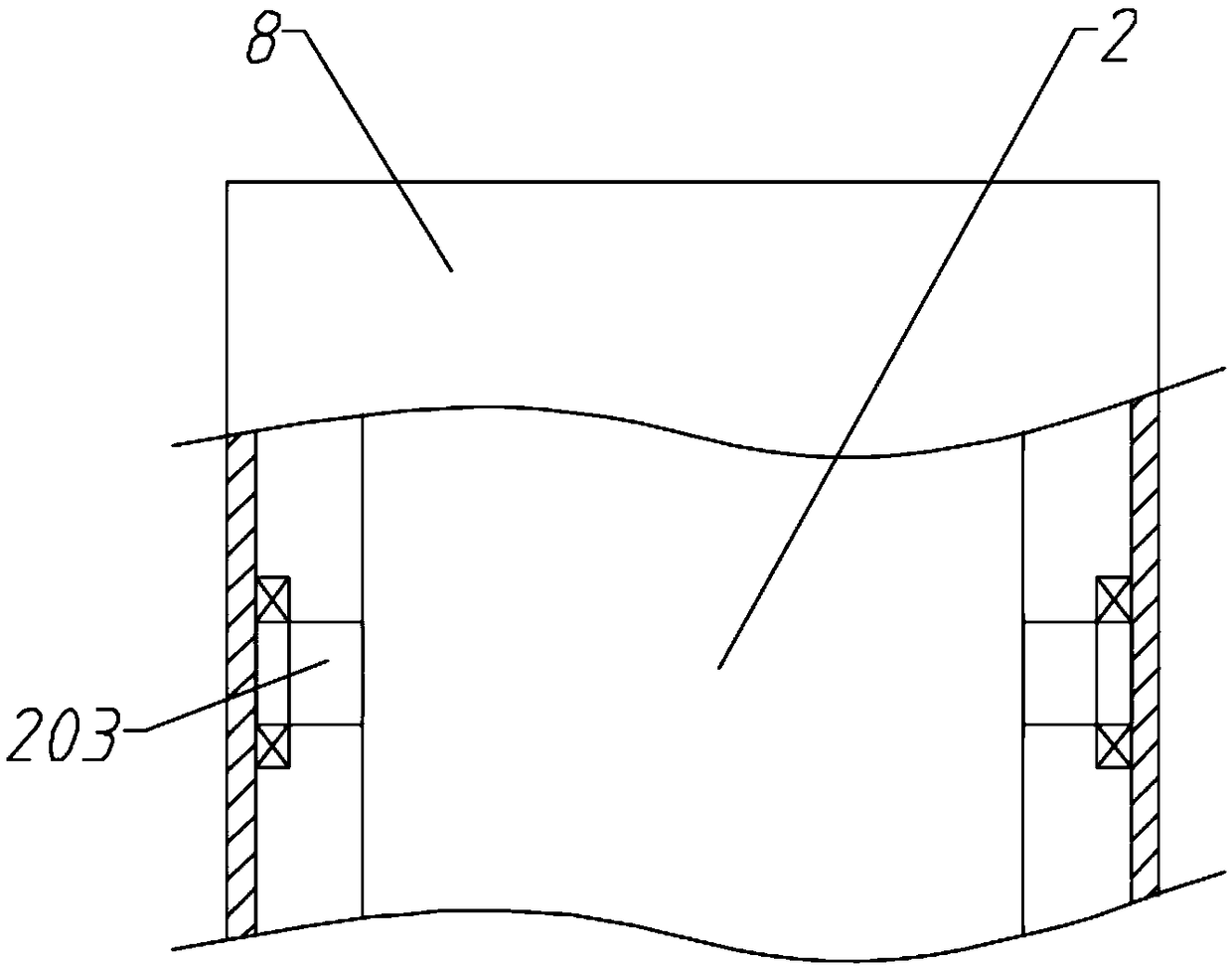

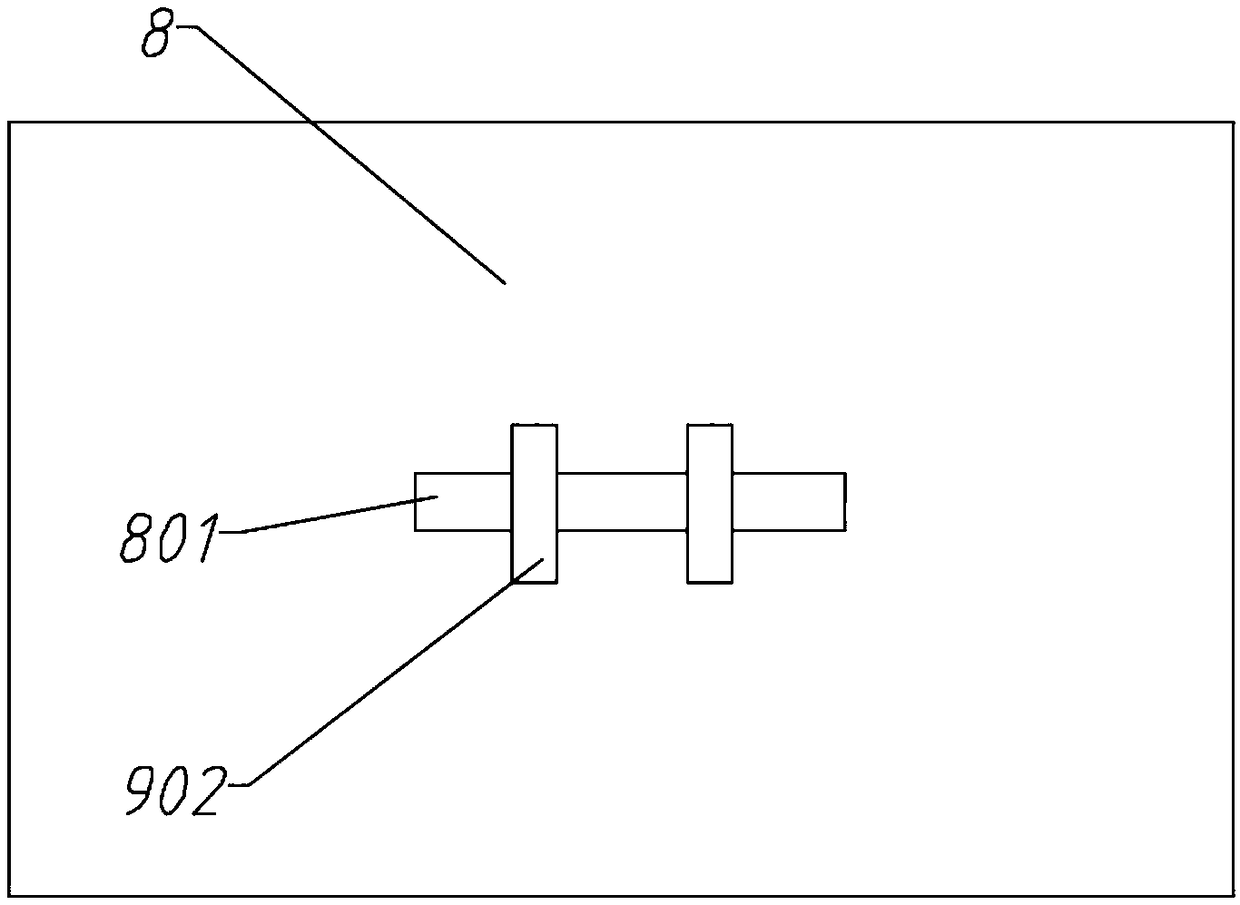

[0040] A multi-angle stirring water and fertilizer mixer, comprising a tank body 1, an inner cover body 2 and an outer cover body 8, the outer cover body 8 is fixedly connected to the top of the tank body 1, the inner cover body 2 is arranged in the outer cover body 8, and the inner cover body 2. The front and rear sides are rotatably connected to the inner wall of the outer cover body 8 through the installation shaft 203;

[0041] A feed pipe 101 is connected to the upper part of one side of the tank body 1, and a discharge pipe 102 is connected to the lower part of the other side;

[0042] There is a No. 1 rotating motor in the center of the inner wall of the rear side of the inner cover body 2, and the motor shaft of the No. 1 rotating motor protrudes forward and is equipped with a No. 1 half gear 4; 4 is located between the two legs of the longitudinal U-shaped frame 3, the two legs of the longitudinal U-shaped frame 3 correspond to the No. 1 and a half gear 4 is provided ...

Embodiment 2

[0053] A multi-angle stirring water and fertilizer mixer, comprising a tank body 1, an inner cover body 2 and an outer cover body 8, the outer cover body 8 is fixedly connected to the top of the tank body 1, the inner cover body 2 is arranged in the outer cover body 8, and the inner cover body 2. The front and rear sides are rotatably connected to the inner wall of the outer cover body 8 through the installation shaft 203;

[0054] A feed pipe 101 is connected to the upper part of one side of the tank body 1, and a discharge pipe 102 is connected to the lower part of the other side;

[0055] There is a No. 1 rotating motor in the center of the inner wall of the rear side of the inner cover body 2, and the motor shaft of the No. 1 rotating motor protrudes forward and is equipped with a No. 1 half gear 4; 4 is located between the two legs of the longitudinal U-shaped frame 3, the two legs of the longitudinal U-shaped frame 3 correspond to the No. 1 and a half gear 4 is provided ...

Embodiment 3

[0068] A multi-angle stirring water and fertilizer mixer, comprising a tank body 1, an inner cover body 2 and an outer cover body 8, the outer cover body 8 is fixedly connected to the top of the tank body 1, the inner cover body 2 is arranged in the outer cover body 8, and the inner cover body 2. The front and rear sides are rotatably connected to the inner wall of the outer cover body 8 through the installation shaft 203;

[0069] A feed pipe 101 is connected to the upper part of one side of the tank body 1, and a discharge pipe 102 is connected to the lower part of the other side;

[0070] There is a No. 1 rotating motor in the center of the inner wall of the rear side of the inner cover body 2, and the motor shaft of the No. 1 rotating motor protrudes forward and is equipped with a No. 1 half gear 4; 4 is located between the two legs of the longitudinal U-shaped frame 3, the two legs of the longitudinal U-shaped frame 3 correspond to the No. 1 and a half gear 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com