A Catadioptric Projection Objective Based on High Numerical Aperture

A technology of high numerical aperture and projection objective lens, which is applied in the field of catadioptric projection objective lens, can solve the problems of increased use cost, limited optical material, and reduced image quality correction effect, so as to reduce the maximum aperture, improve the constraint effect, and reduce the quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

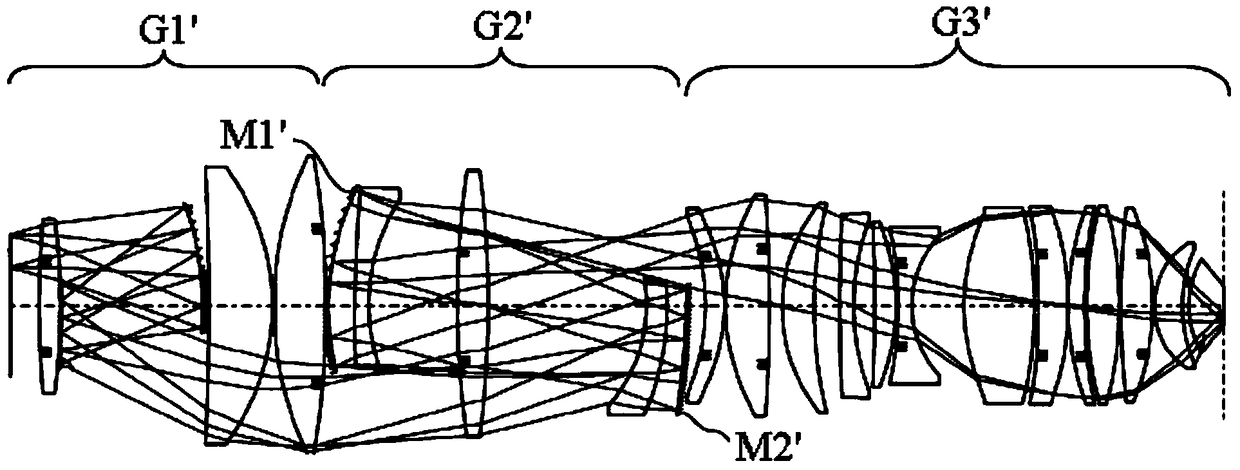

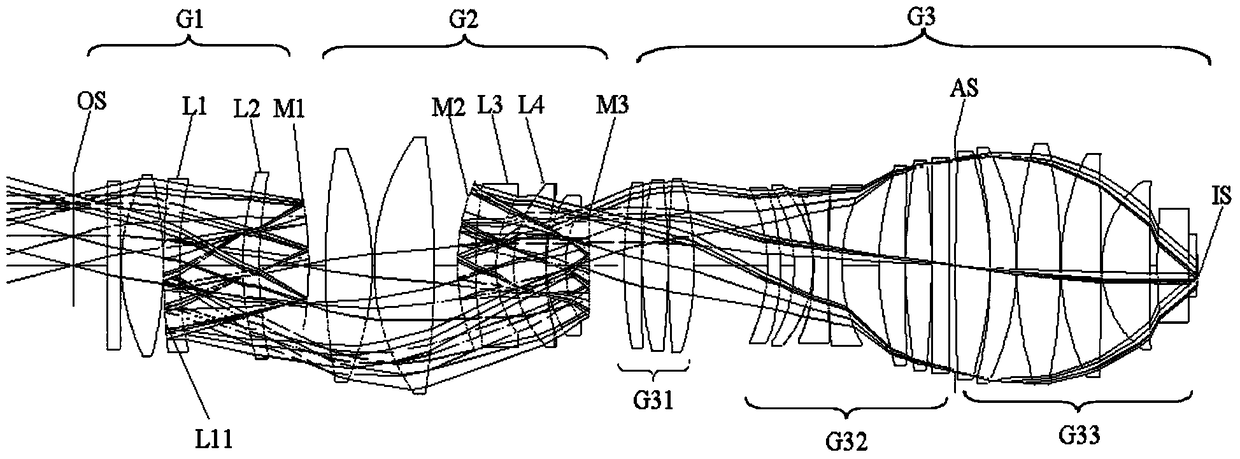

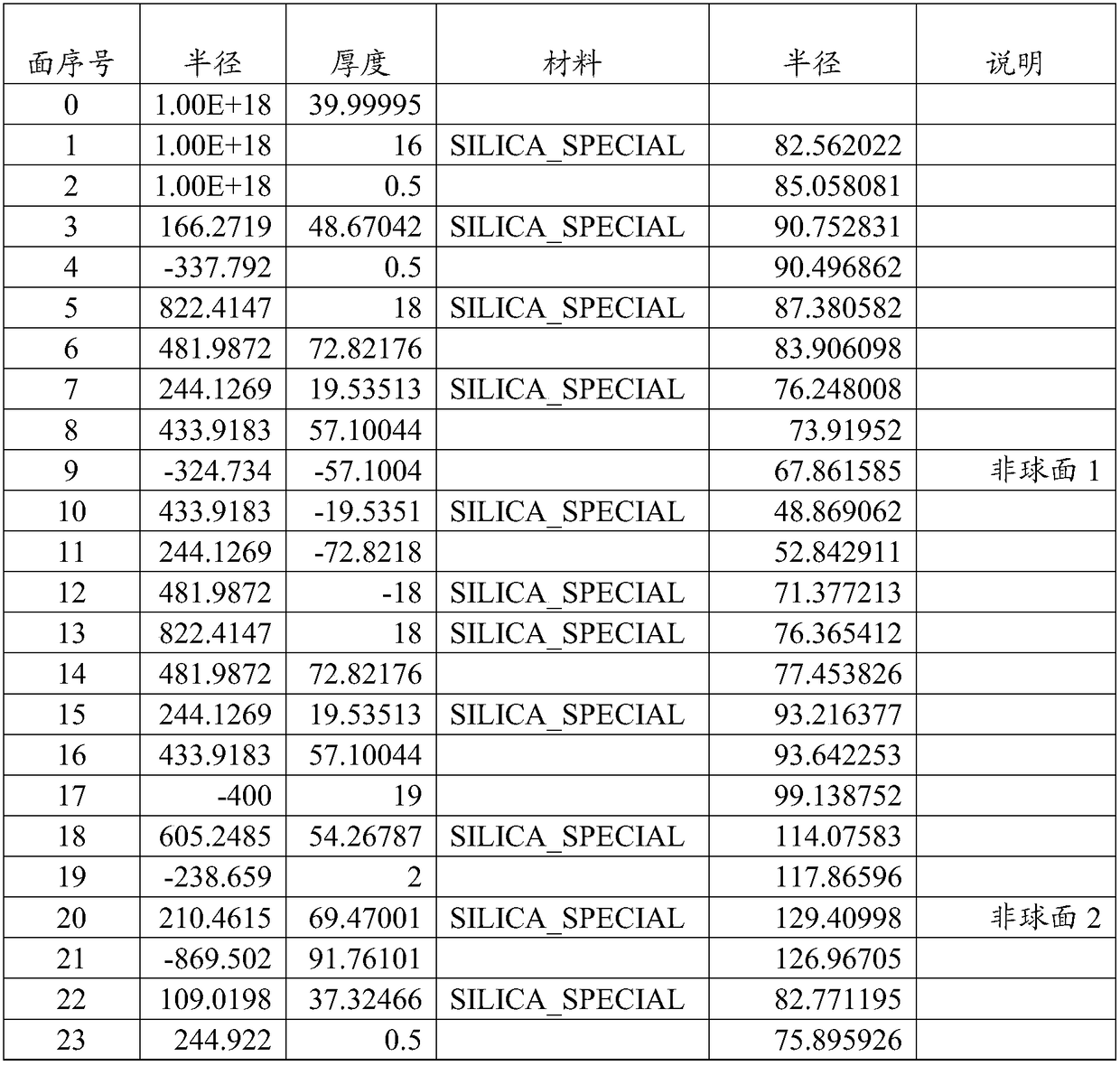

[0021] Such as figure 2 As shown, the present invention provides a catadioptric projection objective based on a high numerical aperture, which is used to image the pattern on the mask OS onto the image plane IS, and is suitable for traditional photolithography machines and imagers with an image-side numerical aperture greater than 0.93. An immersion lithography machine with a square numerical aperture greater than 1.35, which sequentially includes a first lens group G1, a second lens group G2, and a third lens group G3 along the direction of light propagation, and the first lens group G1, the second lens group G2, and the third lens group The three lens groups G3 are on the same optical axis and are all made of fused silica with good internal transmittance and optical quality, which reduces the difficulty of assembly and improves the resolution of the projection objective len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com