Device for directly powering on electric vehicle by ground power supply

A ground power supply and electric vehicle technology, applied in the direction of two-part connecting device, connecting device parts, coupling device, etc., can solve the problems of manual power connection facilities occupying large land and space, increasing charging costs, and hindering traffic. Reach the effect of reducing charging cost, convenient power consumption and high firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Fabrication and installation of ground output devices

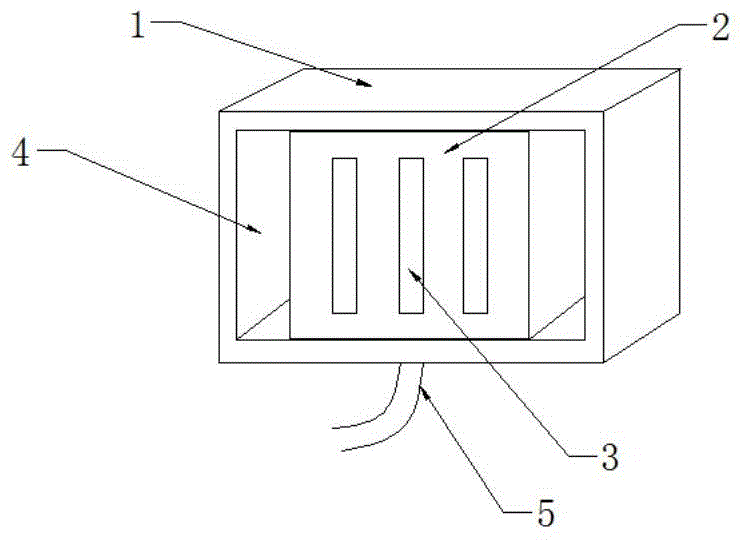

[0044] Weld a 1CM thick steel plate into a rectangular iron box with an inner opening of 8CM*6CM and a depth of 10CM, and drill a 1.5CM threading hole from the center of the long side of the iron box to the bottom.

[0045] Make a special socket with a seat surface of 6CM*6CM and a depth of 10CM with parallel long strip jacks, and make each jack 5CM long and 1CM wide (use the length of the jack to solve the height deviation caused by the weight of the electric vehicle. ).

[0046] Insert and fix the special socket into the iron box. And make a 1CM gap evenly on both sides of the iron box, and pass the socket wire through the hole in the iron box (see figure 1 ).

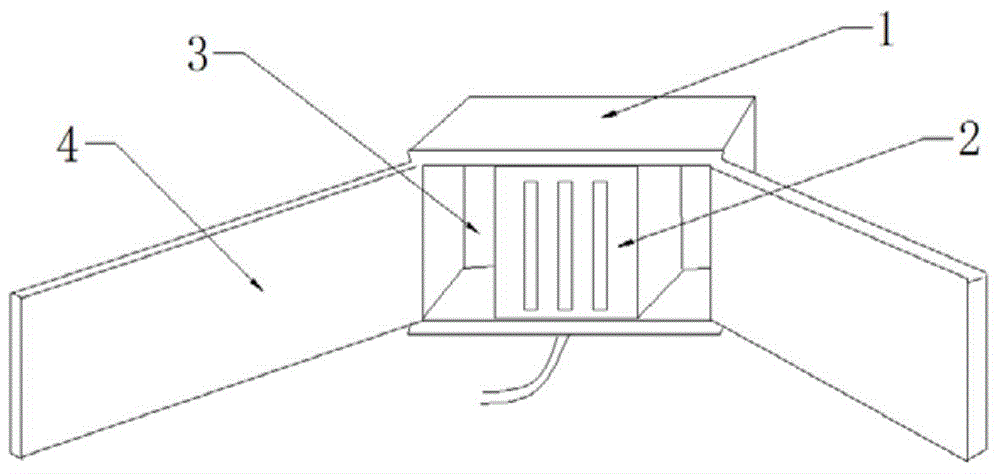

[0047] Take two steel plates with a length of 20CM, a width of 5CM, and a thickness of 1CM, and weld the two steel plates at a 45-degree angle on both sides of the iron box mouth as the lead plate of the socket (see figure 2 ).

[004...

Embodiment 2

[0063] (1) Fabrication and installation of ground installations

[0064] Take a high-elastic steel plate with a length of 30CM and a width of 20CM and a thickness of 0.5CM, and a piece of bakelite board with a length of 45CM and a width of 12CM and a thickness of 1.5CM. 3 pieces of aluminum sheets, two of which are glued to the lower sides of the other side of the bakelite board with resin, with a distance of 4cm between the two aluminum sheets, and the other piece is glued to the middle of the bakelite board, with a distance of 1.5cm between the two aluminum sheets below, on the steel plate Glue an electric plug firmly with resin in the middle of the upper end of the other side, and drill a 1.6MM diameter round hole at the center of the overlapping range of the bakelite board and the steel plate, pass the plug wire through the round hole through the steel plate and the bakelite board and Solder on the three aluminum sheets respectively. At this time, the three aluminum sh...

Embodiment 3

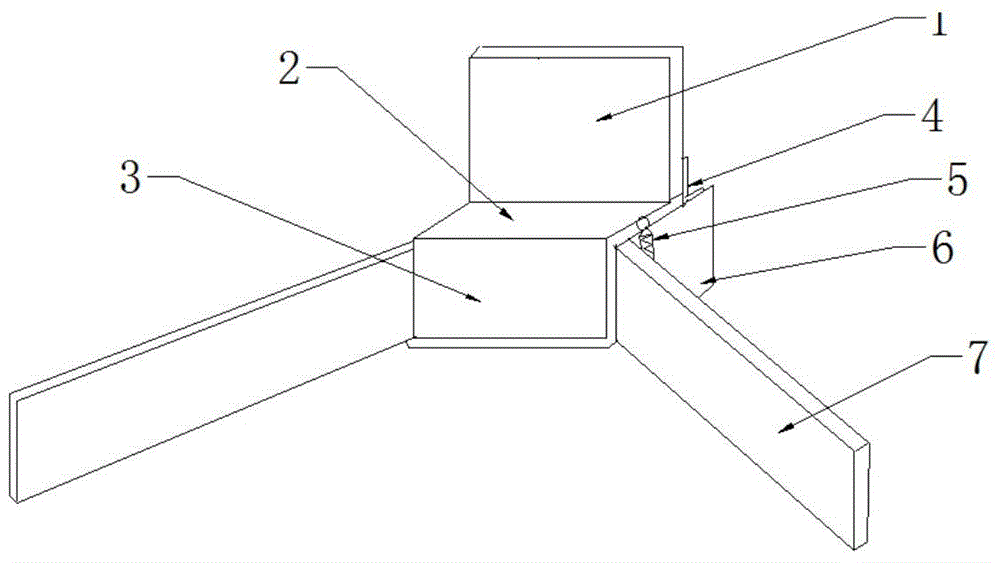

[0075] (1) Fabrication and installation of ground installations

[0076] Take a piece of high elastic steel plate with a length of 35CM, a width of 10CM, and a thickness of 0.5CM, two pieces of magnetic steel with a length of 20CM, a width of 1.5CM, and a thickness of 1CM. , only 5CM steel plate is left on the top of the magnetic steel, and then the bakelite is glued to the steel plate, and then the second piece of magnetic steel is glued to the steel plate, so that the two magnets on the steel plate are exactly the same as the bakelite. Sandwiched in the middle, take 3 pieces of square aluminum sheets with a side length of 3CM and a thickness of 0.3CM, and stick two of them with resin to the lower and two sides of the bakelite board. The aluminum sheets are 2CM apart, and at this time, the three aluminum sheets are in the shape of a character on the bakelite (see Figure 17a ), stick an electric plug with resin in the middle of the upper end of the back of the steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com