Spraying square gun

A nozzle and nozzle technology, which is applied in the field of spray square guns, can solve problems such as deficiencies, and achieve the effects of scientific pressing angle, reasonable and compact overall structure, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

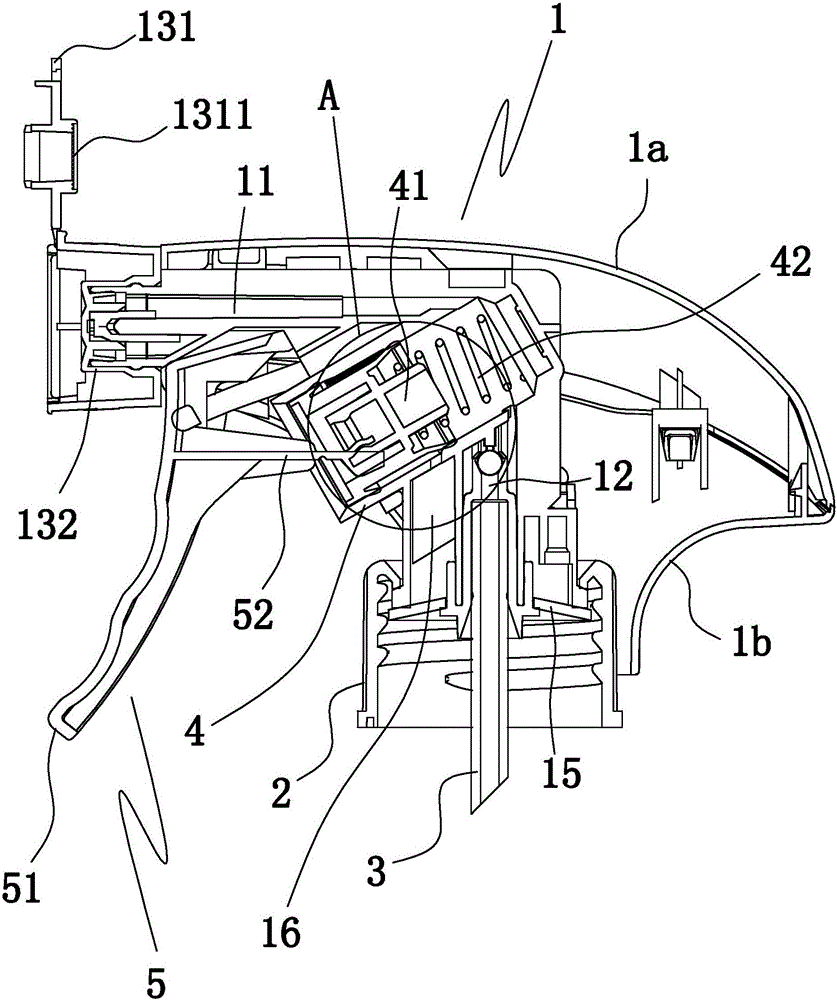

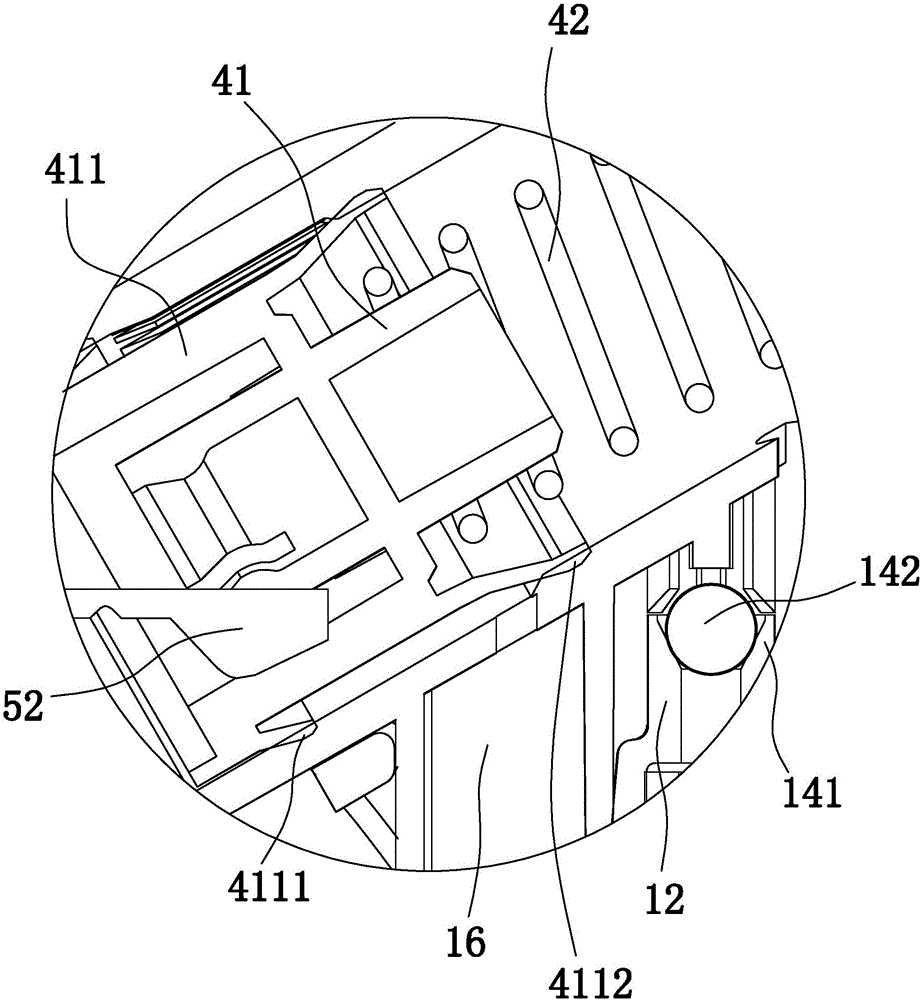

[0020] Embodiment 1: as figure 1 , figure 2 In the shown embodiment, a kind of spray square gun comprises outer cover 1, sleeve cover 2 with internal thread, cover cover is at the lower end of outer cover, is provided with spray pipe in the outer cover, is provided with suction pipe 3 on the outer cover, and spray tube includes spray The pipe section 11, the straight pipe section 12 connected with the injection pipe section, the straight pipe section is connected with the suction pipe, the straight pipe section is provided with a liquid outlet check valve, the direction of the liquid outlet check valve is from bottom to top, and the outer cover is provided with the injection pipe section Connected spout portion, the outer cover is provided with a pressing cylinder 4, the outer end of the pressing cylinder communicates with the outside world, the inner end of the pressing cylinder communicates with the nozzle, the pressing cylinder is provided with a piston 41 that is sliding ...

Embodiment 2

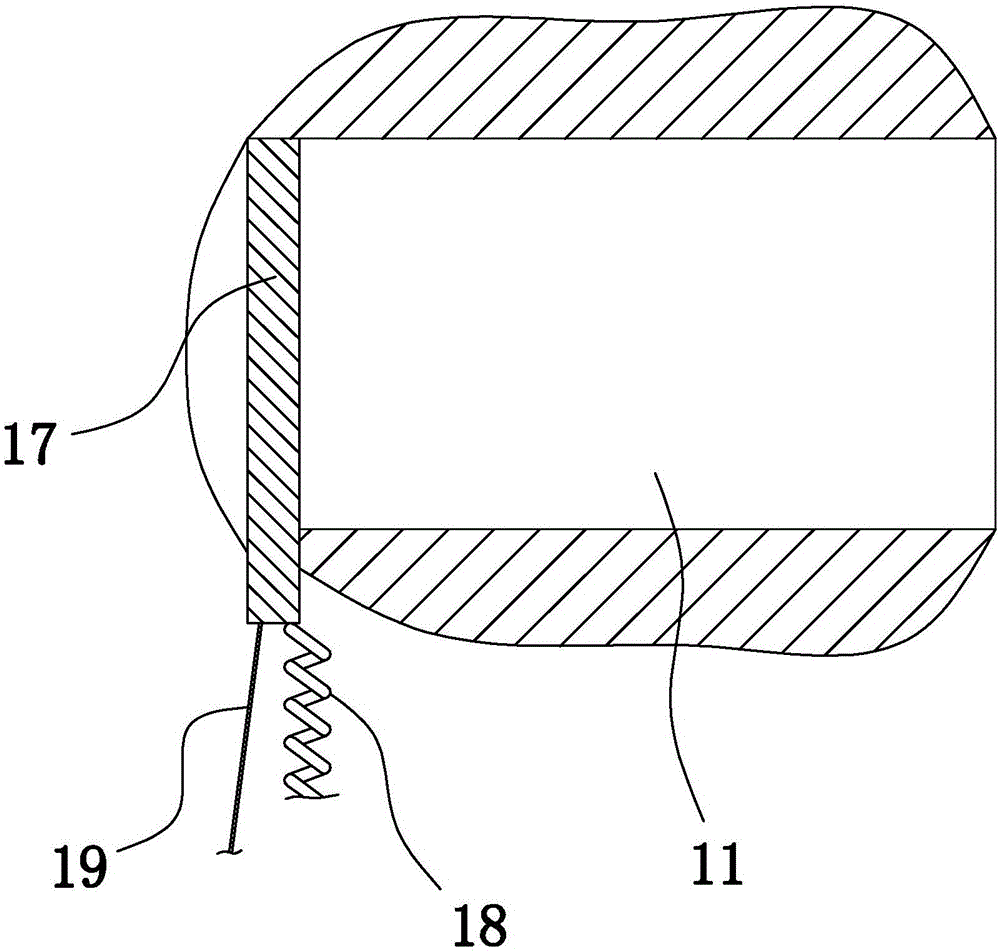

[0029] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as image 3As shown in , the spray pipe section is arranged horizontally, and the connection between the spray pipe section and the nozzle is provided with a partition 17 for cutting off the spray pipe section. The lower end of the clapboard stretches out of the injection pipe section, and the lower end of the clapboard is provided with a reset spring 18 for the upper clapboard, the upper end of the reset spring is connected to the lower end of the clapboard, the lower end of the reset spring is connected to the outer cover, and the wrench is provided with a drag cable 19, one end of which is connected to the The lower end of the partition is connected with a wrench at the other end of the drag cable, and the drag cable is in a tensioned state. The main purpose of using the present invention is to provide fast and powerful "spray". However, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com