Internal-wiring robot revolute joint module

A technology of rotary joints and robots, applied in the field of robots, can solve the problems of difficult elimination of gear gaps, complex structures, and limited rotation range, etc., and achieve the effects of small axial size, simple structure, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

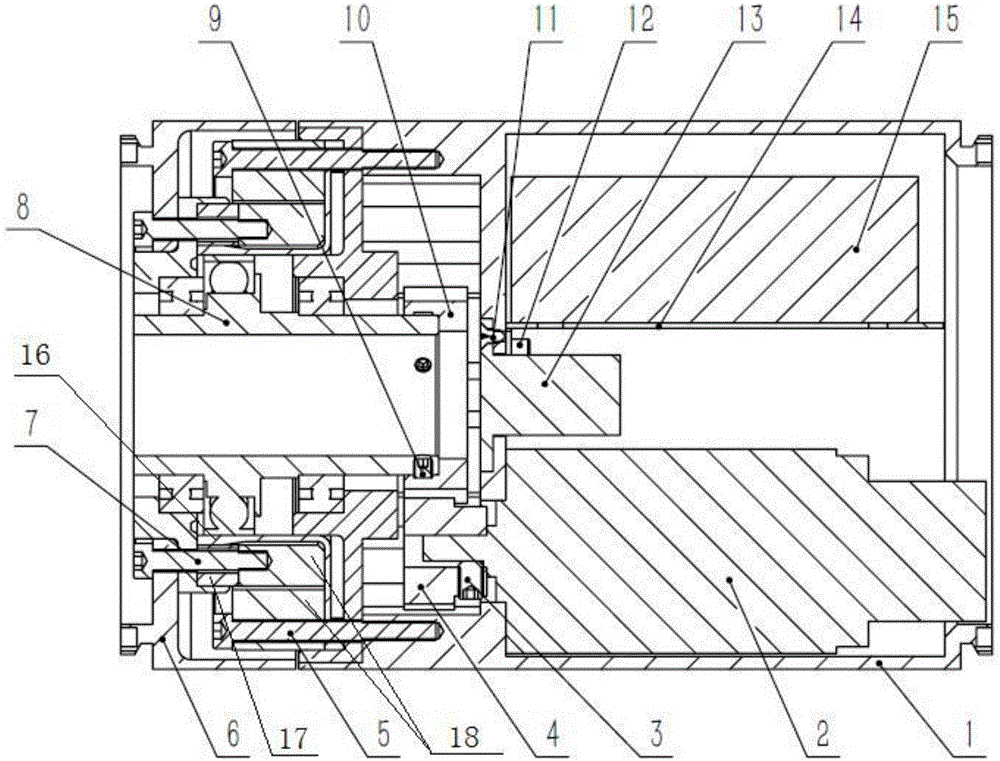

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0025] see figure 1 with figure 2 , the rotary joint module of the inner cable routing robot of the present invention includes a base 1, a joint output member 6, a drive motor 2 and a power transmission mechanism.

[0026] see figure 1 with figure 2 , the interior of the base 1 is divided into a motor installation cavity and a power transmission mechanism installation cavity by a partition plate along the axis direction. The driving motor 2 is arranged in the motor installation cavity. The power transmission mechanism is arranged in the installation chamber of the power transmission mechanism. The power transmission mechanism includes a cylindrical gear transmission mechanism and a harmonic reducer. The main shaft of the drive motor 2 passes through the partition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com