A tilting mechanism for an injection mold

A technology of inclined roof mechanism and injection mold, which is applied in the field of injection mold, can solve the problems affecting the demoulding quality of products, and achieve the effect of improving convenience, good waterproof sealing effect, and flexible assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

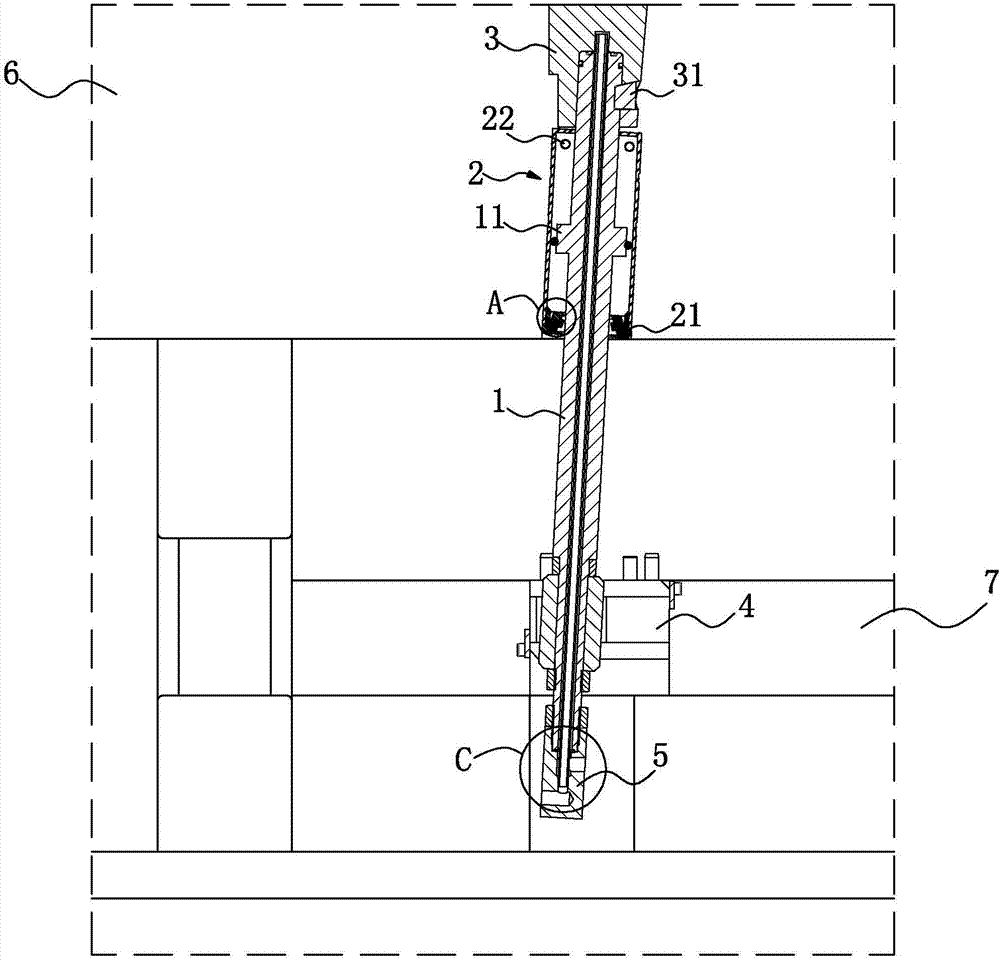

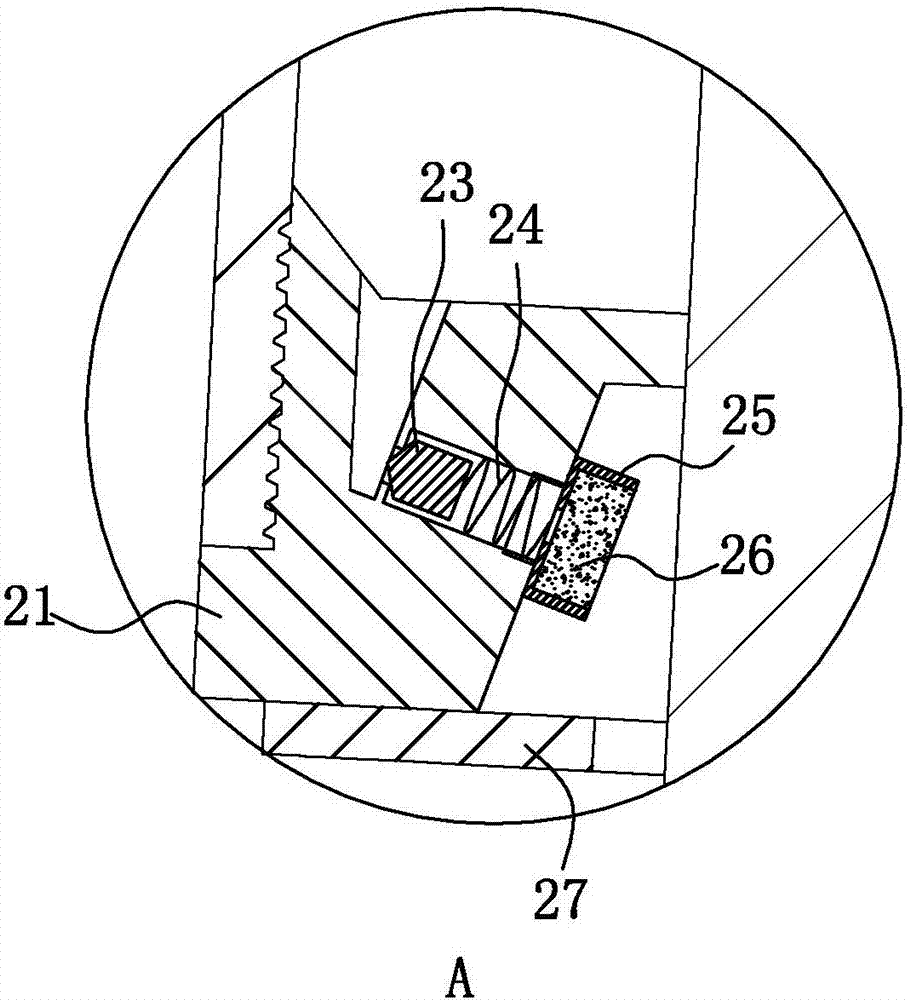

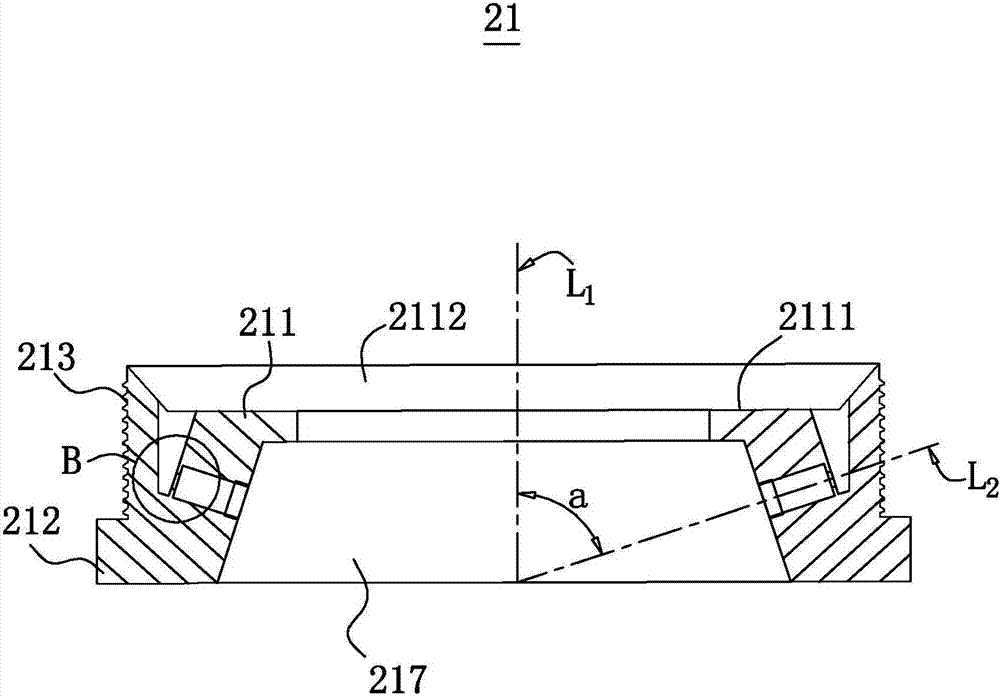

[0048] See figure 1 , An inclined top mechanism of an injection mold, including inclined top rod 1, cylinder body 2, inclined top block 3, sliding seat 4 and water collector 5. The inclined top block 3 is arranged at the end of the inclined top rod 1, and the key 31 is matched to make the inclined top block 3 and the inclined top rod 1 fixed; the cylinder block 2 is sleeved outside the inclined top rod 1, and a piston 11 is provided on the outer wall of the inclined top rod 1. The piston 11 is housed in the cylinder block 2, in the cylinder The bottom of the body 2 is threadedly connected with a mounting block 21. After disassembly and installation, the entire cylinder body 2 is a hollow arrangement with a lower end opening 113. The outer wall of the top of the cylinder body 2 is provided with two air inlet holes 22. 6 will be provided with a ventilation channel communicating with the outside, and the air inlet hole 22 is in communication with the ventilation channel, but the nu...

Embodiment 2

[0061] See Figure 11 to Figure 13 The difference from the first embodiment lies in the design of the piston 11. In this embodiment, the piston 11 is set in a cup shape, also made of fluoroelastomer, with its opening 113 facing, and the piston 11 has a piston 11 seat. The seat is clamped on the inclined top rod 1.

[0062] The specific working principle is: when the inclined mandrel 1 is lifted and demolded, the piston 11 is deformed by the pressure of the air above, causing the opening 113 to shrink. At this time, a gap is formed between the piston 11 and the inner wall of the cylinder 2, and the air is driven from the gap. Enter under the piston 11 until the demolding process is completed; when the inclined mandrel 1 is pulled back into position, the piston 11 is compressed, and the inner wall of the opening 113 of the piston 11 is deformed by the pressure of the air, causing the piston 11 to flatten the piston. The edge of the opening 113 of 11 is close to the inner wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com