Car Seat Packaging Bag Making Machine

A technology for car seats and packaging bags, which is applied in packaging, bag making operations, transportation and packaging, etc. It can solve the problems of using a large labor force, and achieve the effects of reducing costs, increasing production speed, and reducing personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings.

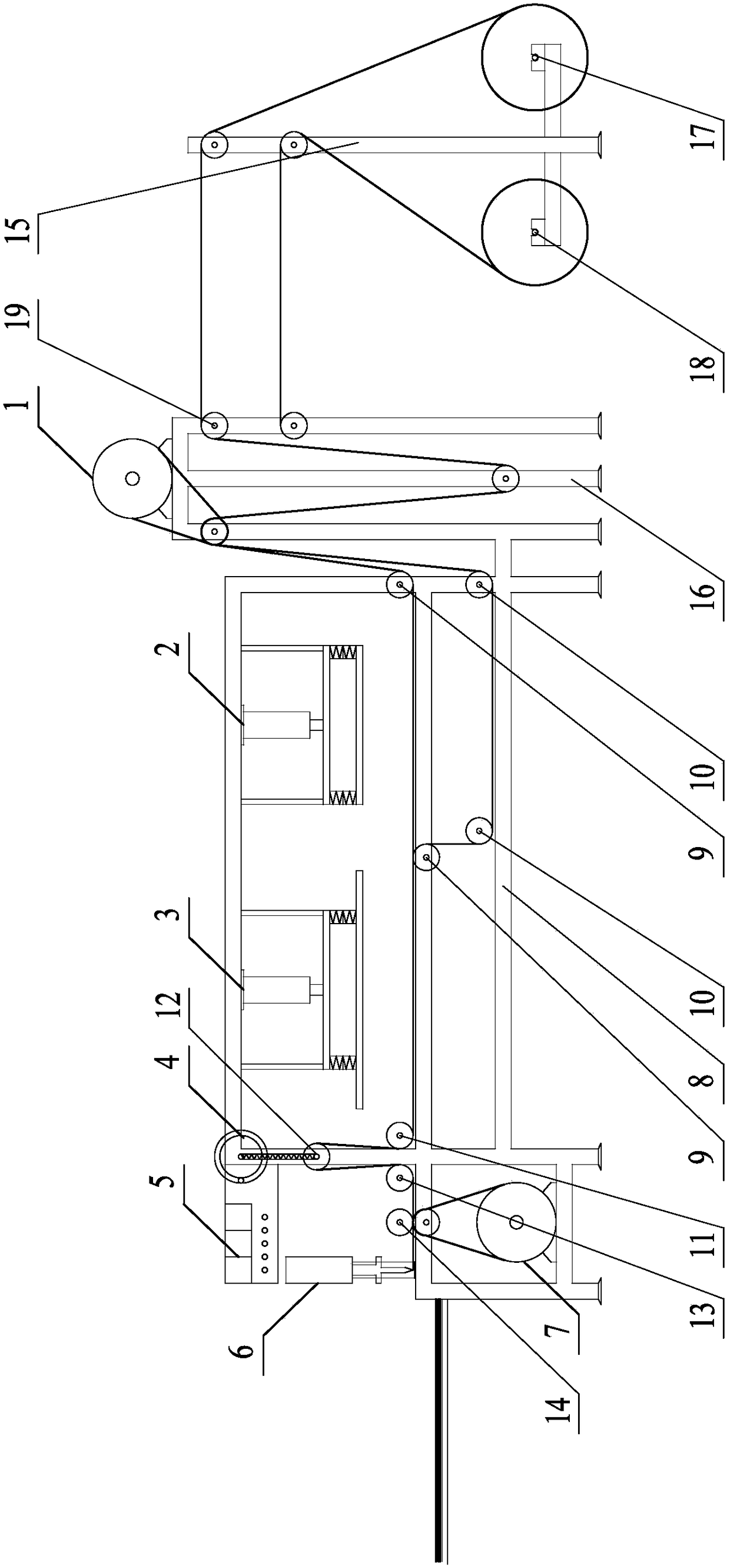

[0015] Such as figure 1 As shown: the car seat packaging bag making machine includes a feeding traction motor 1, a pneumatic electric ironing knife for headrest bags 2, a pneumatic electric ironing knife for packaging bag appearance 3, a length adjustment wheel 4, a touch control screen 5, and a pneumatic electric heating cut-off Ironing knife 6, main traction motor 7, working frame 8, upper conveying roller 9, lower conveying roller 10, first discharging roller 11, length adjusting roller 12, second discharging roller 13, traction roller group 14, Raw material frame 15, feeding traction frame 16, upper layer raw material drum 17, lower layer raw material drum 18, feed roller 19, etc.

[0016] Such as figure 1 As shown, the car seat packaging bag making machine of the present invention includes a working frame 8, a feeding mechanism is installed at the feeding end of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com