Calibrating device for spinning frame roller side boundary gauge

A calibration device and spinning frame technology, applied in the direction of textiles and papermaking, can solve the problems of increased verticality error, inability to detect or calibrate, and easy wear of cylindrical surfaces, so as to ensure accuracy and technical requirements and improve flat car The effect of quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The verification device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

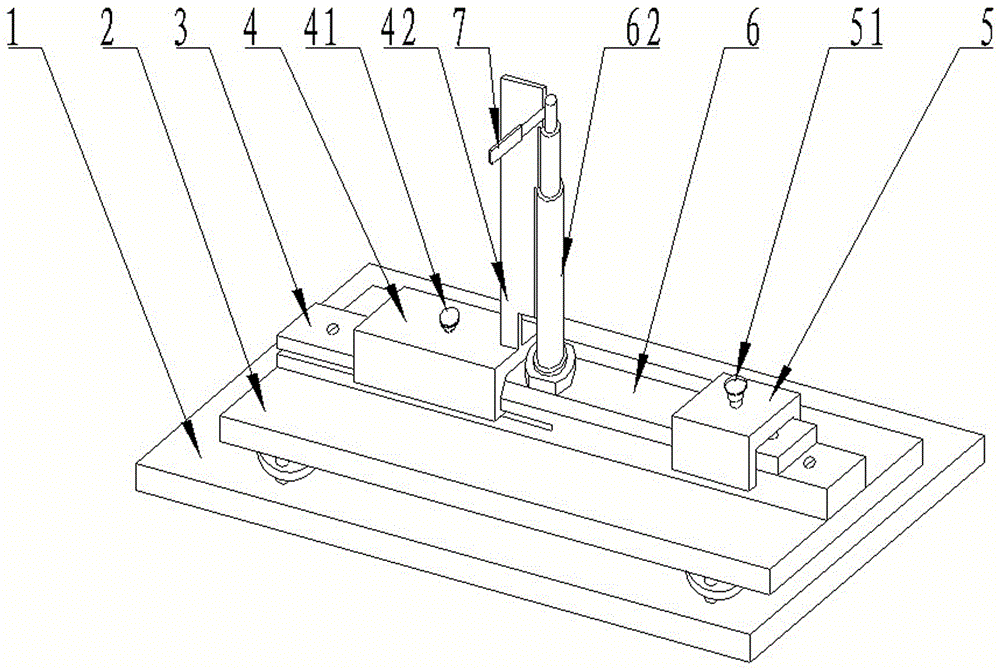

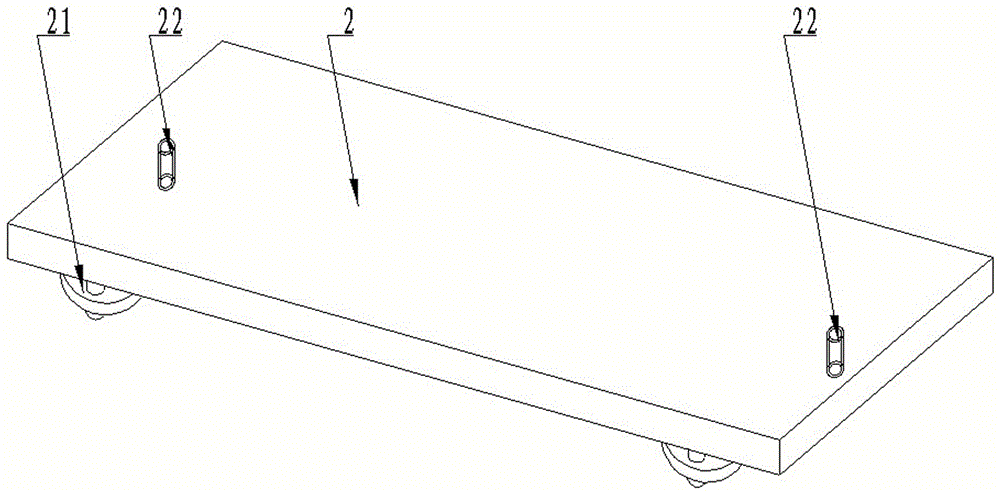

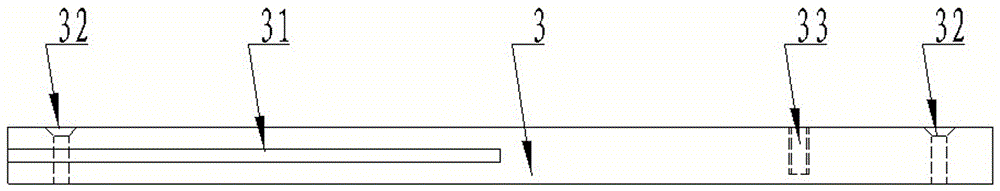

[0023] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 It can be seen that the device for verifying the roller sidelines of the spinning frame of the present invention comprises a base 1, a detection plate 2 is arranged on the base 1, a parallel block 3 is arranged above the center line of the detection plate 2, and the two sides of the parallel block 3 The left end of the side is provided with a concave groove 31 along the midline, and a detection component 4 is arranged in the concave groove 31. One end of the parallel block 3 is provided with a positioning component 5, and the positioning component 5 is fixed on the parallel block 3 by a positioning bolt 51. Above, a roller sideline gauge 6 is arranged between the detection component 4 and the positioning c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com