Micro-region temperature and moisture regulating device for air-jet loom

A temperature and humidity adjustment, air-jet loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of warp passage resistance, shortened device service life, low humidification efficiency, etc., to improve air supply efficiency and prolong use. Effect of life and motor power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

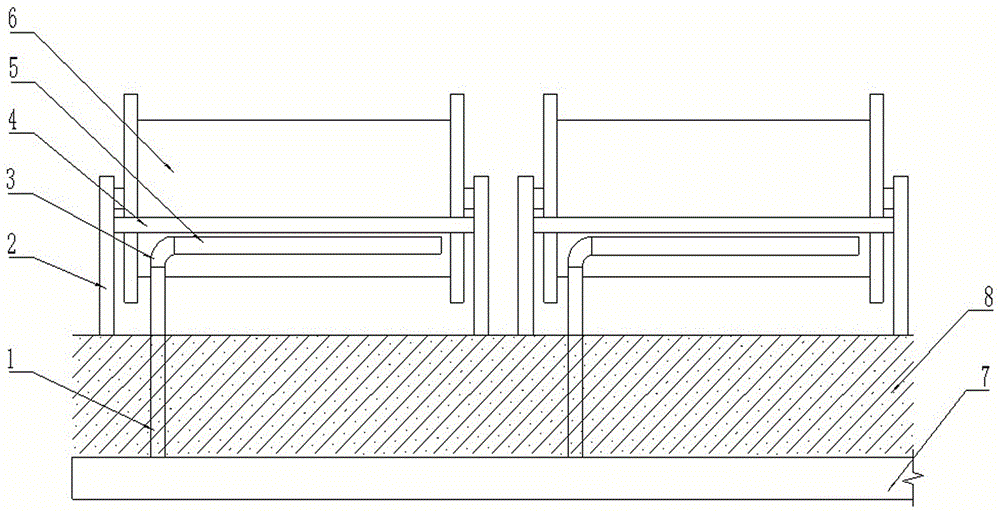

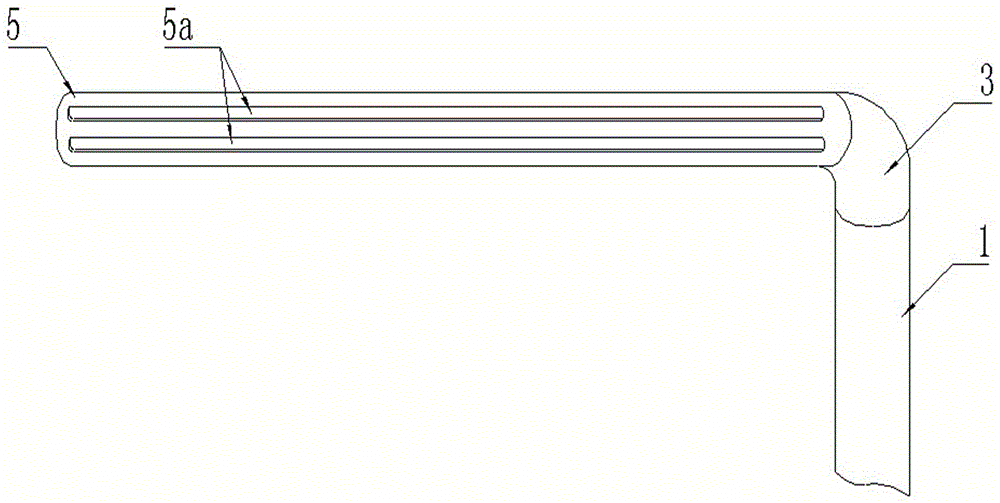

[0011] like figure 1 , figure 2 As shown, a small-area temperature and humidity adjustment device for an air-jet loom of the present invention includes a main air duct 7, the main air duct 7 is arranged below the concrete floor 8, and a number of weaving shafts are respectively arranged by brackets 2 above the concrete floor 8 6. The main air duct 7 is provided with a branch air pipe 1 corresponding to the weaving shaft 6, and the other ends of the branch air pipe 1 are respectively connected to a horizontal air pipe 5 through an elbow 3, and the horizontal air pipe 5 is arranged in parallel Below one side of the weaving shaft 6, the horizontal air pipes 5 are respectively provided with a plurality of strip-shaped air outlets 5a, and the air supply angle of the strip-shaped air outlets 5a points to the lower half of the weaving shaft 6; Cover 4, the transparent cover 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com