Rolling bearing comprising wear ring and related manufacture method

A rolling bearing, anti-wear technology, applied in the direction of rolling contact bearings, rotating bearings, bearings, etc., can solve the problem of increasing the number of bearing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

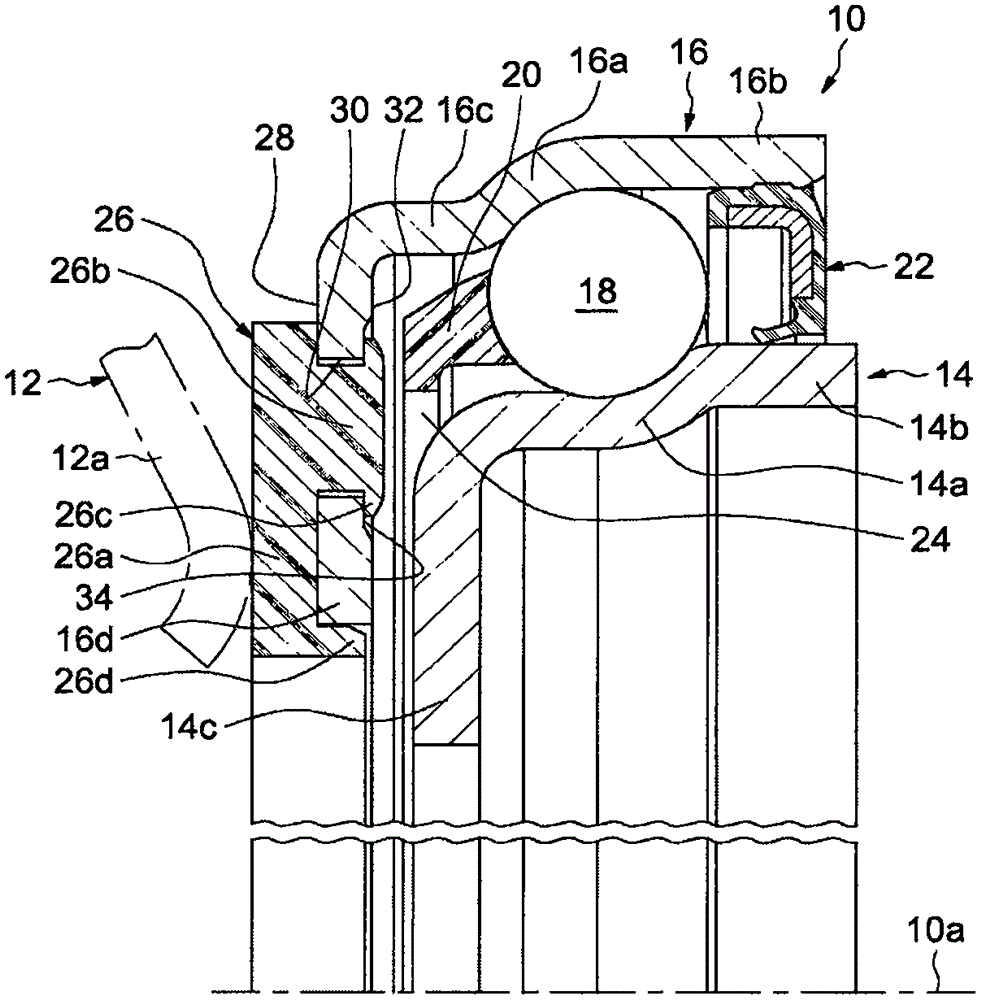

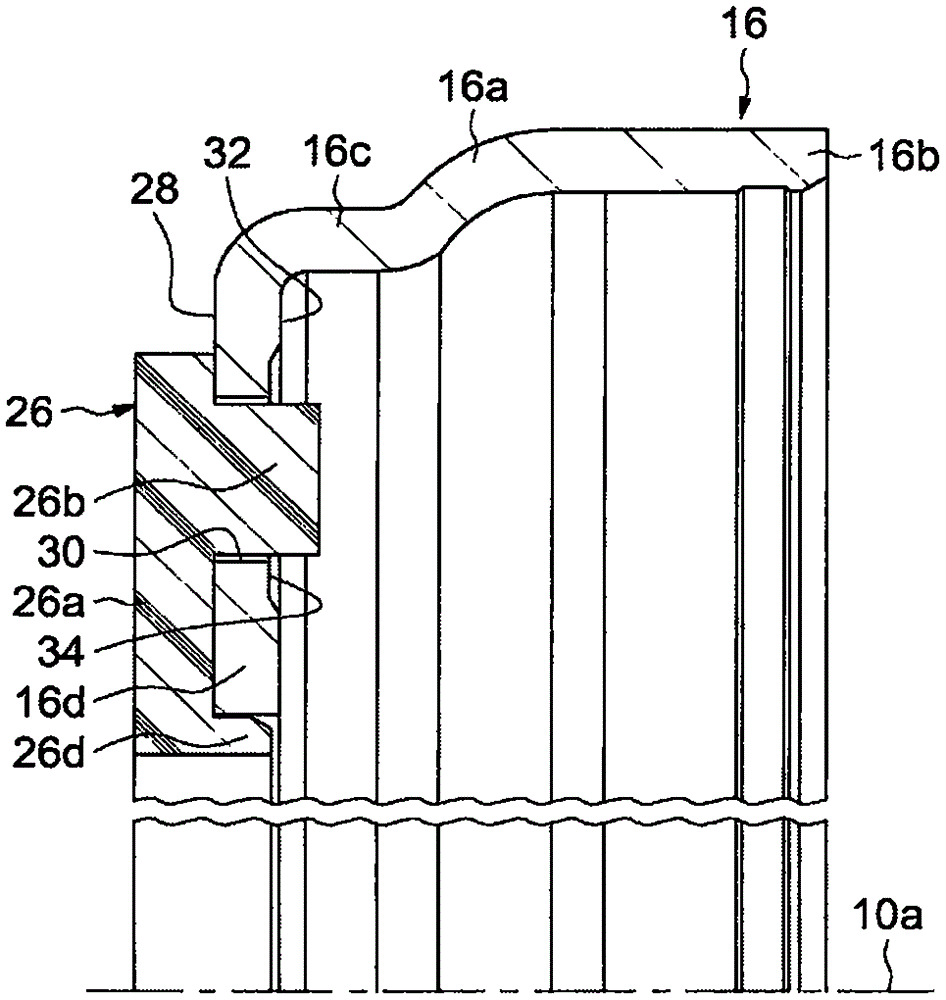

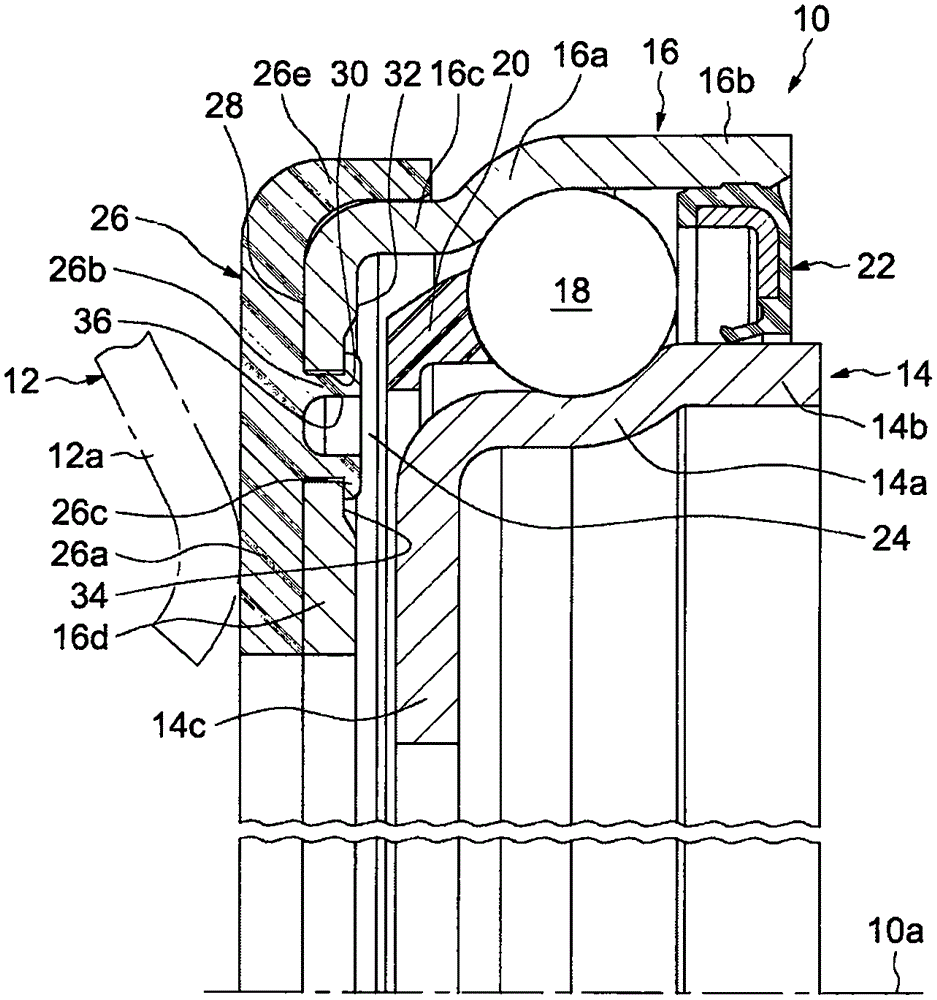

[0024] exist figure 1 , the rolling bearing of which the entire assembly is referenced 10 is intended to be used in a separator release bearing arrangement arranged to act on a diaphragm 12 of a clutch, in particular for a motor vehicle. In this figure, the diaphragm 12 is partially shown and indicated by dashed lines. The diaphragm 12 includes a plurality of rods 12a spaced apart in the circumferential direction. The rolling bearing 10 is intended to be mounted on an operating member (not shown) of an associated separator release bearing arrangement and arranged to move axially.

[0025] Rolling bearing 10 with axis 10a comprises a non-rotating inner ring 14, a rotating outer ring 16, a row of rollers made here in the form of balls and arranged radially between the rolling paths provided on said rings. The member 18, the cage 20 for maintaining the regular circumferential spacing of the rolling members 18, and the annular sealing washer 22 fixed on the outer ring. A rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com