Union type single tube pass floating head heat exchanger

A single-tube heat exchanger technology, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as inconvenient installation and maintenance, high assembly requirements, and sealing leakage, etc., to achieve Easy to disassemble, ensure sealing, and reduce the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

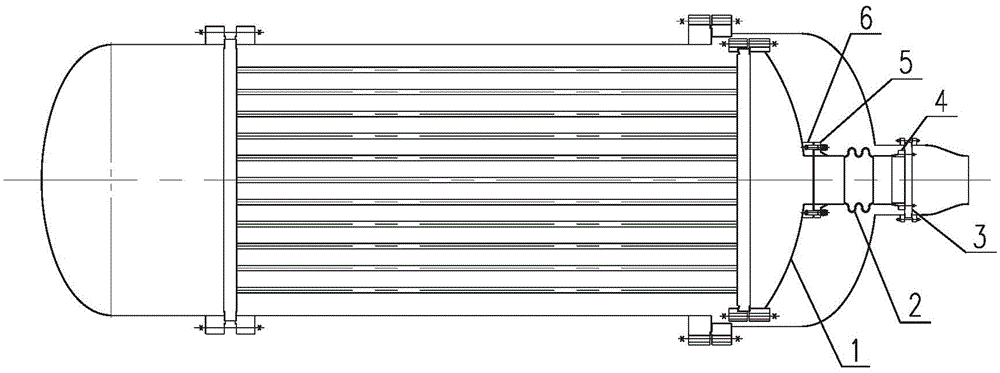

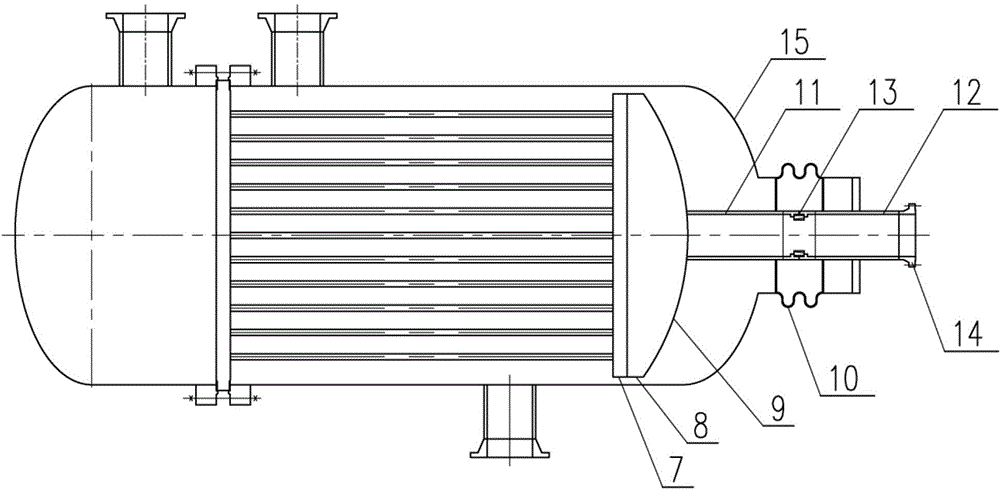

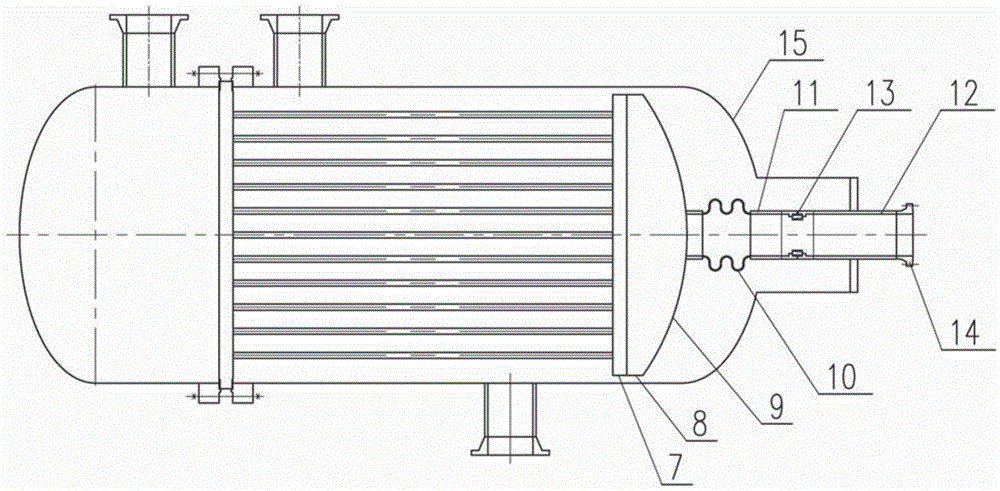

[0048] Such as diagram 2-1 with Figure 2-2 , image 3 As shown, the expansion joint 10 is set on the shell side, and the outer head cover is set to place the short joint of the expansion joint. The floating tube sheet 7 is directly connected with the cylinder body 8 (or head 9) (the cylinder body may not be designed.), and the floating head The connecting pipe 11 on the floating head is directly connected with the sealing head 9, the connecting pipe 12 on the outer head cover is directly connected with the outer head cover 15, and the connecting pipe 11 on the floating head and the connecting pipe 12 on the outer head cover are directly connected by a union 13. Connection terminal 16 is image 3the shape shown. The two connection terminals 16 are installed on an axis, and the two ends are respectively welded to the connecting pipe 11 on the floating head and the connecting pipe 12 on the outer head cover. The inner surface of the end of the connection terminal 16 is proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com