A hydraulically controlled flushing box-type wave-making device and method

A wave-making device and punching box technology, which is applied to measuring devices, instruments, and the use of repeated force/pulsation force to test the strength of materials, etc., can solve the problems affecting the accuracy of model test results, troubles in wave model tests, and low frequency of wave simulation. problem, to achieve the effect of authenticity and credibility of the test process, strong comprehensive application ability, and elimination of the influence of reflected waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

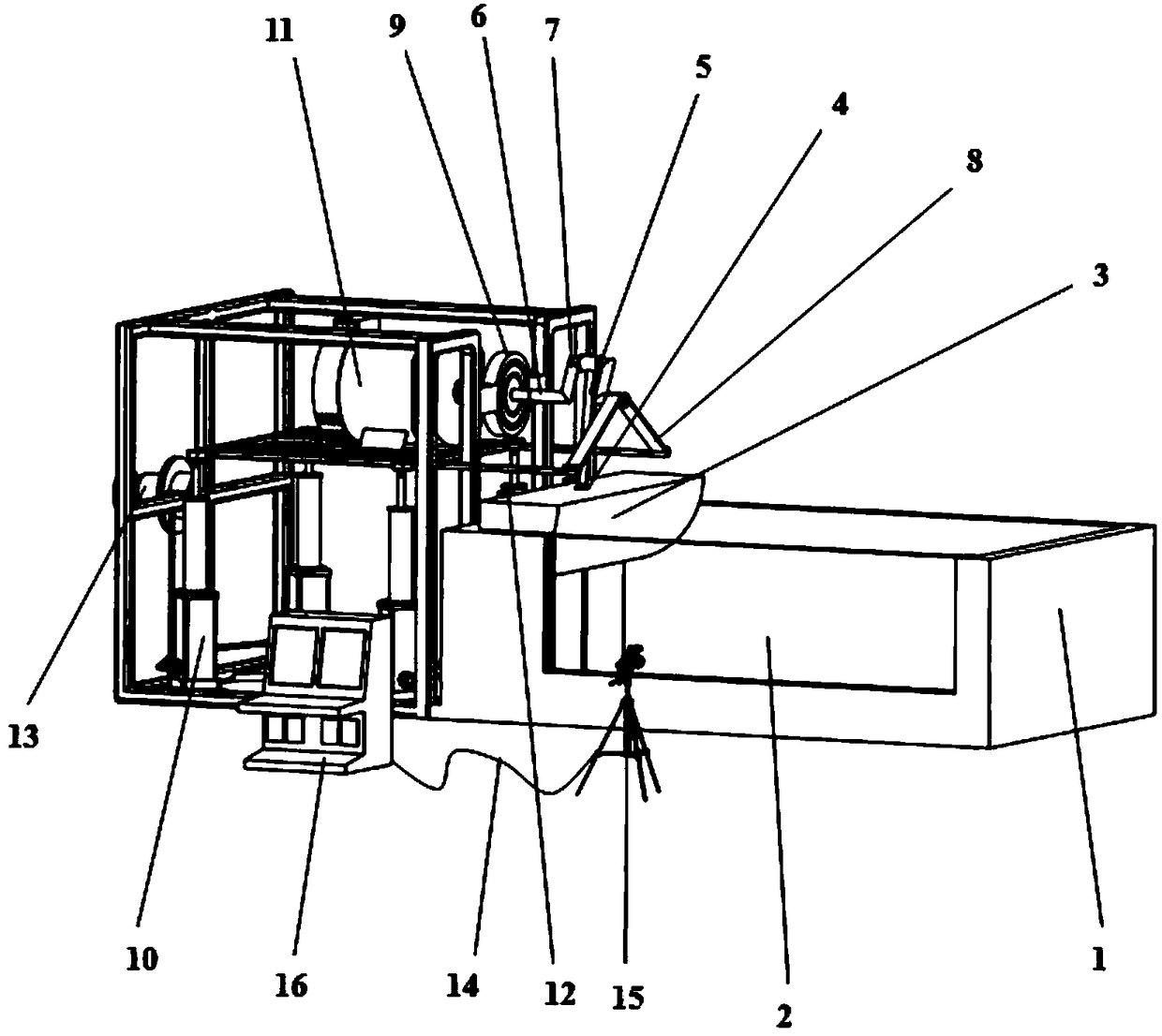

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, a hydraulically controlled punching box type wave-making device includes a test channel 1; tempered glass 2; punching box 3; ball joint 4; transmission rod 5; rotating shaft 6; camshaft 7; fixed bracket 8; Hydraulic jack 10; Motor 11; Guide rail 12; Hydraulic controller 13; Data connection line 14; High-speed camera 15; Ocean wave spectrum display 16;

[0027] The punching box 3 is connected with a transmission rod through a ball joint, and the power end of the transmission rod is driven to move up and down by a camshaft 7. The camshaft 7 is connected with the output shaft of the motor 11, and is driven by the motor 11 to rotate, so The motor 11 described above is driven to move up and down by a set of hydraulic drive device, and real-time control of wave amplitude, frequency and phase is realized by adjusting the elevation and rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com