Laminated hanging basket device of lead-acid battery plate pack machine

A technology of lead-acid battery and plate wrapping machine, which is applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. It can solve the problems of plate rollover, low stacking efficiency, and inconvenient maintenance, and improve Efficiency, not easy to rollover, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

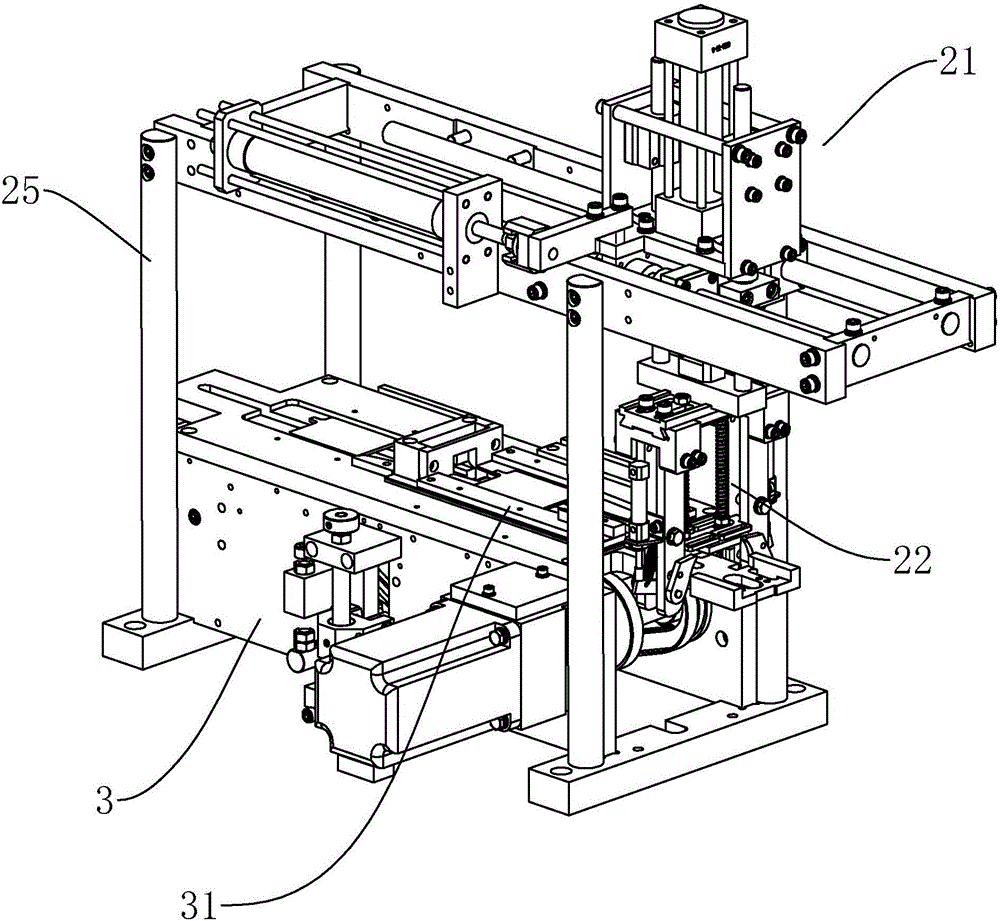

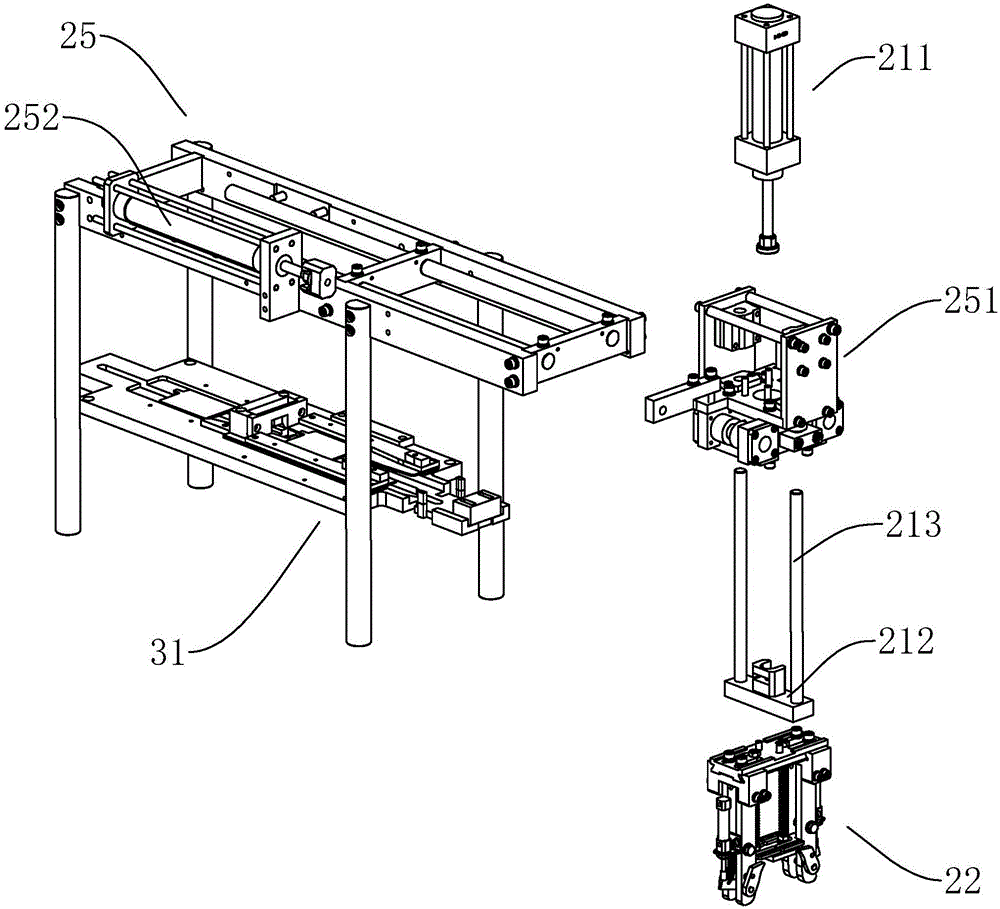

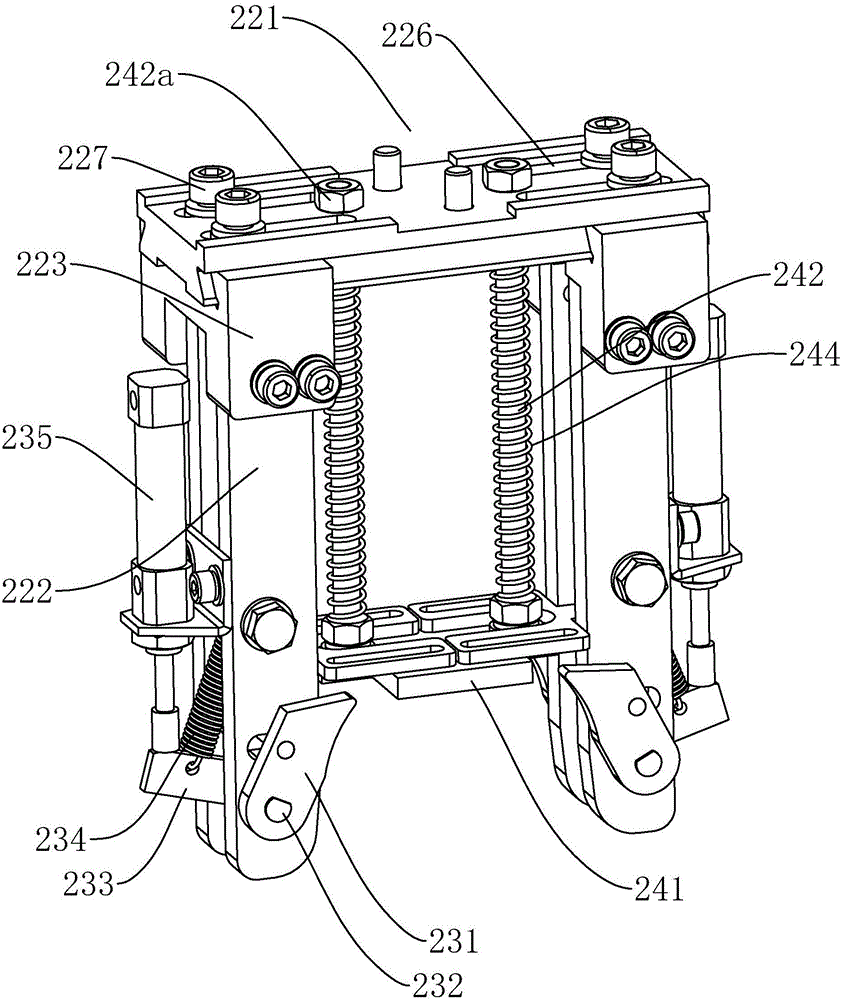

[0025] refer to Figure 1 to Figure 6 , Figure 1 to Figure 6 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a lamination hanging basket device of a lead-acid battery cladding machine includes a frame 25, a lifting mechanism 21 and a hanging basket mechanism 22. The frame 25 A lifting seat 251 is slidably arranged on the upper side through a sliding column mechanism, and a hanging basket longitudinal movement driving mechanism capable of driving the lifting seat 251 to slide is configured on the frame 25, and the lifting mechanism 21 includes a lifting cylinder arranged on the lifting seat 251 211, the vertical movement driving mechanism of the hanging basket includes a vertical movement cylinder 252 arranged on the side of the frame 25, the ejector rod of the vertical movement cylinder 252 is connected to the vertical movement cylinder 252, and a device for conveying the pole plate is arranged under the frame 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com