Rigid-flex circuit board and manufacturing method thereof

A combination of soft and hard, manufacturing method technology, applied in the direction of multi-layer circuit manufacturing, printed circuit components, structural connection of printed circuits, etc., can solve the problems of large alignment deviation, unfavorable high density and thin design, etc., to reduce area, reducing defects, and improving alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

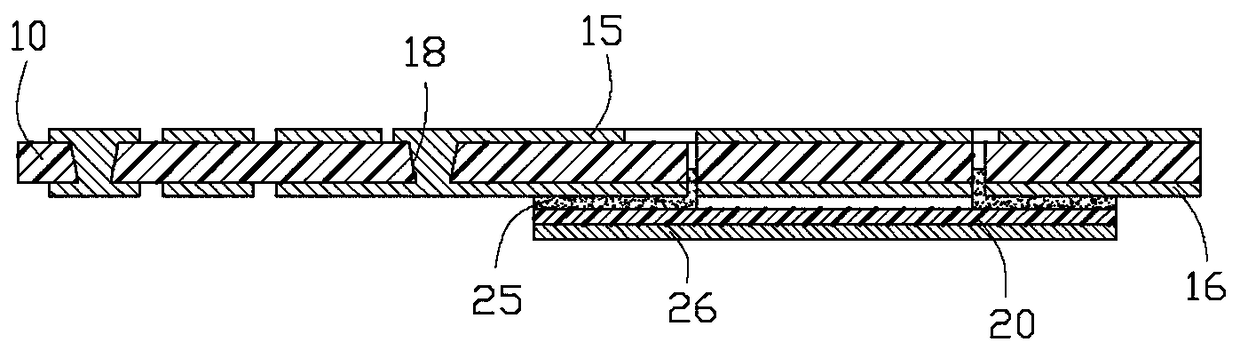

[0054] The manufacturing method of the soft-rigid circuit board provided by the technical solution includes the following steps:

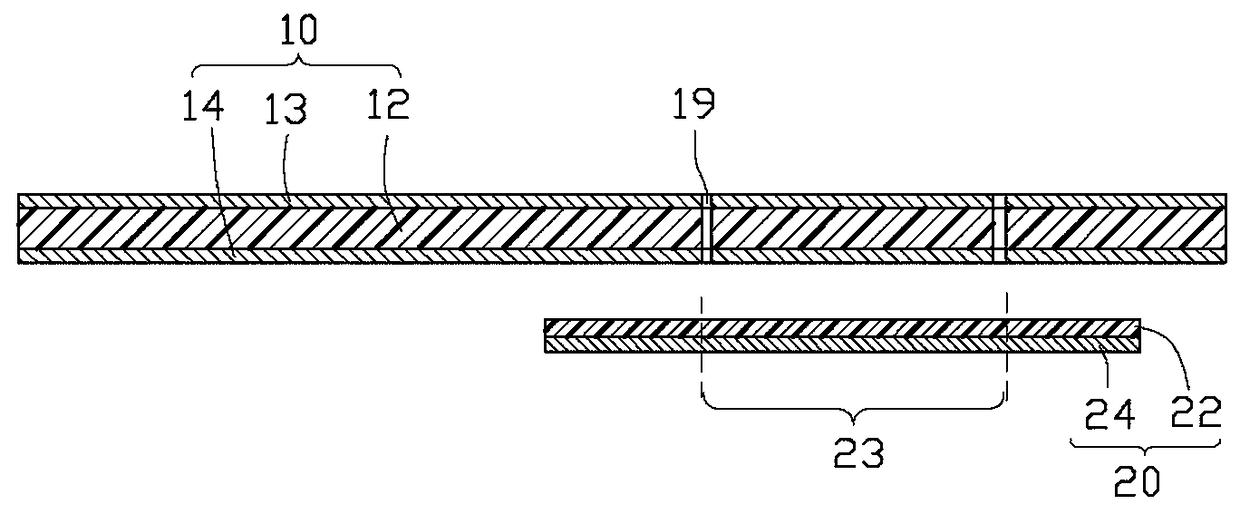

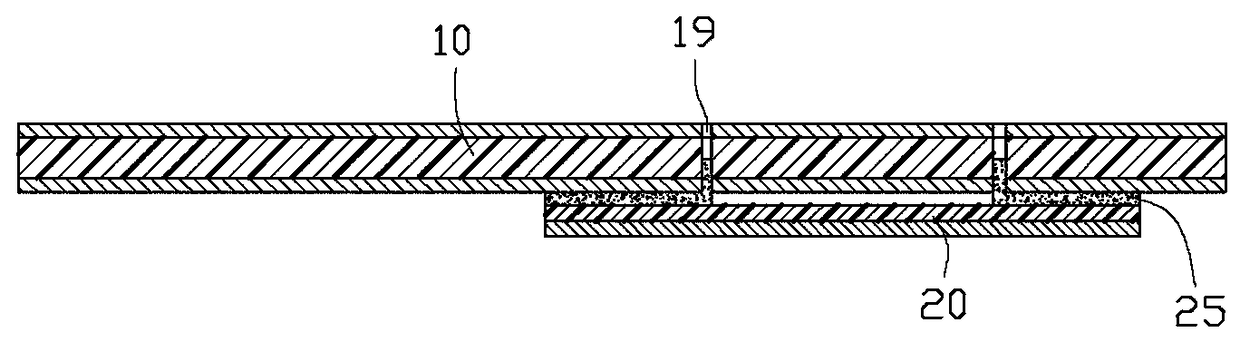

[0055] For a first step, see figure 1 , providing a core layer 10 and a flexible substrate 20 .

[0056] The core layer 10 includes a base layer 12 , a first copper foil 13 and a second copper foil 14 . The first copper foil 13 and the second copper foil 14 are coated on both sides of the base layer 12 respectively.

[0057] The flexible substrate 20 includes a base plate 22 and a flexible copper foil 24 formed on the surface of the base plate 22 .

[0058] The flexible substrate 20 includes a flexible region 23 . The flexible region 23 corresponds to the bending region after the subsequent rigid-flex board is formed.

[0059] The core layer 10 is pre-fractured (by drilling or scooping) to form two pre-fracture openings 19 . The two pre-slits 19 are formed on the core layer and arranged parallel to each other. The two pre-splitting openings 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com